0206.GB

E 8

3 Starting up the truck

F

Before the truck can be commissioned, operated or a load unit lifted, the driver must

ensure that there is nobody within the hazardous area.

Checks and operations to be performed before starting daily work

– Check the whole of the outside of the truck for signs of damage and leaks.

– Check the battery attachment and wire connections for damage, make sure they

are secure.

– Check the battery connector is secure.

– Check the overhead guard for damage.

– Check the load handler for visible damage such as cracks, bent or severely worn

load forks.

– Check the load wheels for damage.

– Make sure the load chains are evenly tensioned.

– Make sure all safety mechanisms are correct and working.

– For rail guidance systems check the guide rollers are smooth and not damaged.

F

It is forbidden for more than one person to enter the driver’s cab at a time.

Adjusting the driver’s seat

– Pull up the adjusting lever and add or remove weight to obtain the correct height.

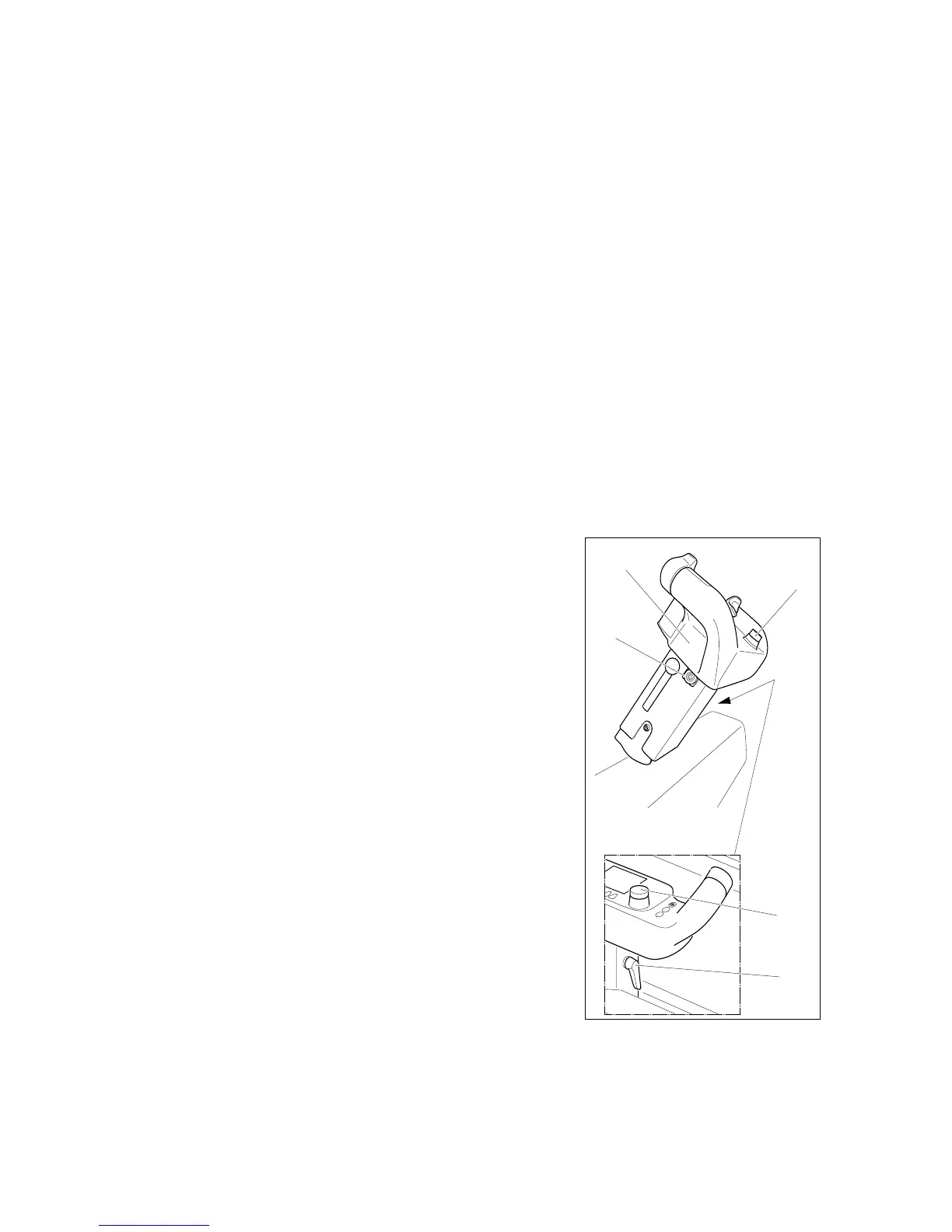

Control panel angle adjustment

Z

The control panel can be tilted to one of 5 positions.

– Press the control panel (1) to the right and adjust

the angle until the pin engages again.

Control panel height adjustment

– Release the lever (3).

– Position the control panel (upwards or downwards)

– Apply the lever (3).

To prepare the truck for operation

– Close the safety gates securely on both sides.

– Turn the EMERGENCY DISCONNECT switch (18)

to loosen it.

– Put the key in the key switch (2) and turn it

clockwise.

– Test the warning device (horn).

– Test the operating and parking brakes.

– Carry out a reference/test run on the lift mast to

adjust the height display (see page E 8).

F

Press the EMERGENCY DISCONNECT switch

immediately if the truck starts to move or lift when it

is switched on.

F

Brief steering movements arising from steering referencing are permissible.

18

2

18

3

1

0206.GB

E 8

3 Starting up the truck

F

Before the truck can be commissioned, operated or a load unit lifted, the driver must

ensure that there is nobody within the hazardous area.

Checks and operations to be performed before starting daily work

– Check the whole of the outside of the truck for signs of damage and leaks.

– Check the battery attachment and wire connections for damage, make sure they

are secure.

– Check the battery connector is secure.

– Check the overhead guard for damage.

– Check the load handler for visible damage such as cracks, bent or severely worn

load forks.

– Check the load wheels for damage.

– Make sure the load chains are evenly tensioned.

– Make sure all safety mechanisms are correct and working.

– For rail guidance systems check the guide rollers are smooth and not damaged.

F

It is forbidden for more than one person to enter the driver’s cab at a time.

Adjusting the driver’s seat

– Pull up the adjusting lever and add or remove weight to obtain the correct height.

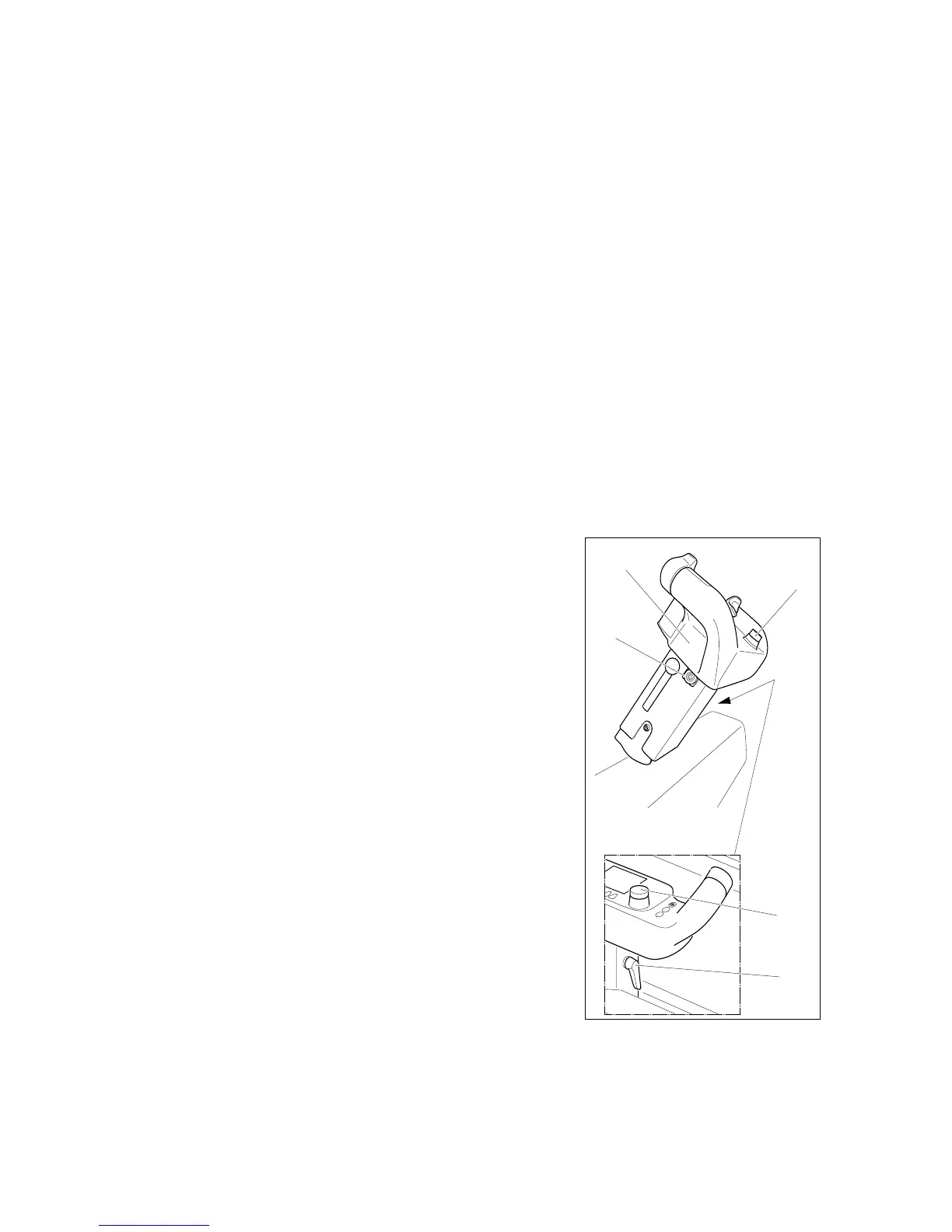

Control panel angle adjustment

Z

The control panel can be tilted to one of 5 positions.

– Press the control panel (1) to the right and adjust

the angle until the pin engages again.

Control panel height adjustment

– Release the lever (3).

– Position the control panel (upwards or downwards)

– Apply the lever (3).

To prepare the truck for operation

– Close the safety gates securely on both sides.

– Turn the EMERGENCY DISCONNECT switch (18)

to loosen it.

– Put the key in the key switch (2) and turn it

clockwise.

– Test the warning device (horn).

– Test the operating and parking brakes.

– Carry out a reference/test run on the lift mast to

adjust the height display (see page E 8).

F

Press the EMERGENCY DISCONNECT switch

immediately if the truck starts to move or lift when it

is switched on.

F

Brief steering movements arising from steering referencing are permissible.

18

2

18

3

1

Loading...

Loading...