1298.GB

F 10

5.5 Inspecting the hoisting chains

Excessive wear and exterior damages:

According to the official regulations a chain is to be considered as worn-off, when it

has stretched by 3% in the section around the guide pulley. For safety reasons, the

manufacturer recommends to replace the chain when it has stretched by 2%.

If exterior damages are noticeable the chain is to be replaced immediately, since the-

se damages will lead to fatigue fractures.

m

If the truck is equipped with two sets of hoisting chains, the chains must always be

replaced in pairs. Only this guarantees a balanced load distribution to both chains.

When replacing the chain, the link pins between chain latch and the chain itself must

also be replaced. Only original replacement parts of the manufacturer may be used.

5.6 Repairing the chain

Only original replacement parts of the manufacturer may be used when repairing a

chain. The rivet heads must be ground-off before dismounting. This prevents the pin

from damaging the borehole when being forced through the intermediate ring respec-

tively the inner link. Dismounted pins and rings may not be re-used.

5.7 Changing the transmission oil

m

Under no circumstances oil may be allowed to enter the ground or the sewer system.

Waste oil must be securely stored until it is disposed of properly.

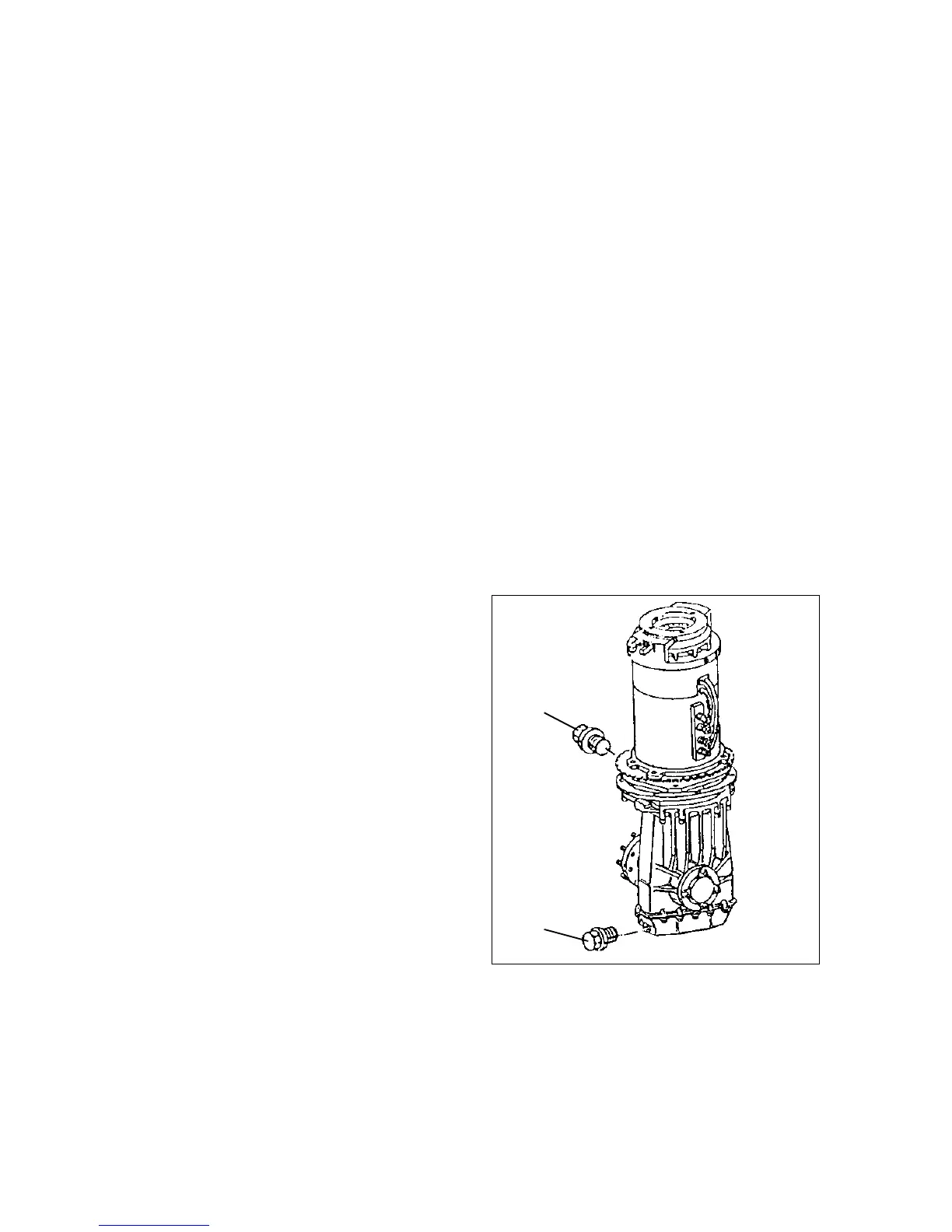

Draining the oil:

– Place an oil pan under the transmissi-

on.

– Open the oil drain plug (7) at the trans-

mission bottom and drain the oil.

Refilling oil:

– Screw in oil drain plug (7) and tighten.

– Open the oil level and filling plug (6) at

the transmission top.

– Fill with new transmission oil up to the

oil level plug opening.

– Screw in the oil level and filling plug

(6).

A

Since the waste oils must be disposed of

in accordance with the applicable envi-

ronmental protection regulations and be-

cause special tools and skills may be required for changing transmission oil, hydraulic

oil, and brake fluid as well for replacing filters, these operations should be performed

by the manufacturer’s service personnel.

6

7

1298.GB

F 10

5.5 Inspecting the hoisting chains

Excessive wear and exterior damages:

According to the official regulations a chain is to be considered as worn-off, when it

has stretched by 3% in the section around the guide pulley. For safety reasons, the

manufacturer recommends to replace the chain when it has stretched by 2%.

If exterior damages are noticeable the chain is to be replaced immediately, since the-

se damages will lead to fatigue fractures.

m

If the truck is equipped with two sets of hoisting chains, the chains must always be

replaced in pairs. Only this guarantees a balanced load distribution to both chains.

When replacing the chain, the link pins between chain latch and the chain itself must

also be replaced. Only original replacement parts of the manufacturer may be used.

5.6 Repairing the chain

Only original replacement parts of the manufacturer may be used when repairing a

chain. The rivet heads must be ground-off before dismounting. This prevents the pin

from damaging the borehole when being forced through the intermediate ring respec-

tively the inner link. Dismounted pins and rings may not be re-used.

5.7 Changing the transmission oil

m

Under no circumstances oil may be allowed to enter the ground or the sewer system.

Waste oil must be securely stored until it is disposed of properly.

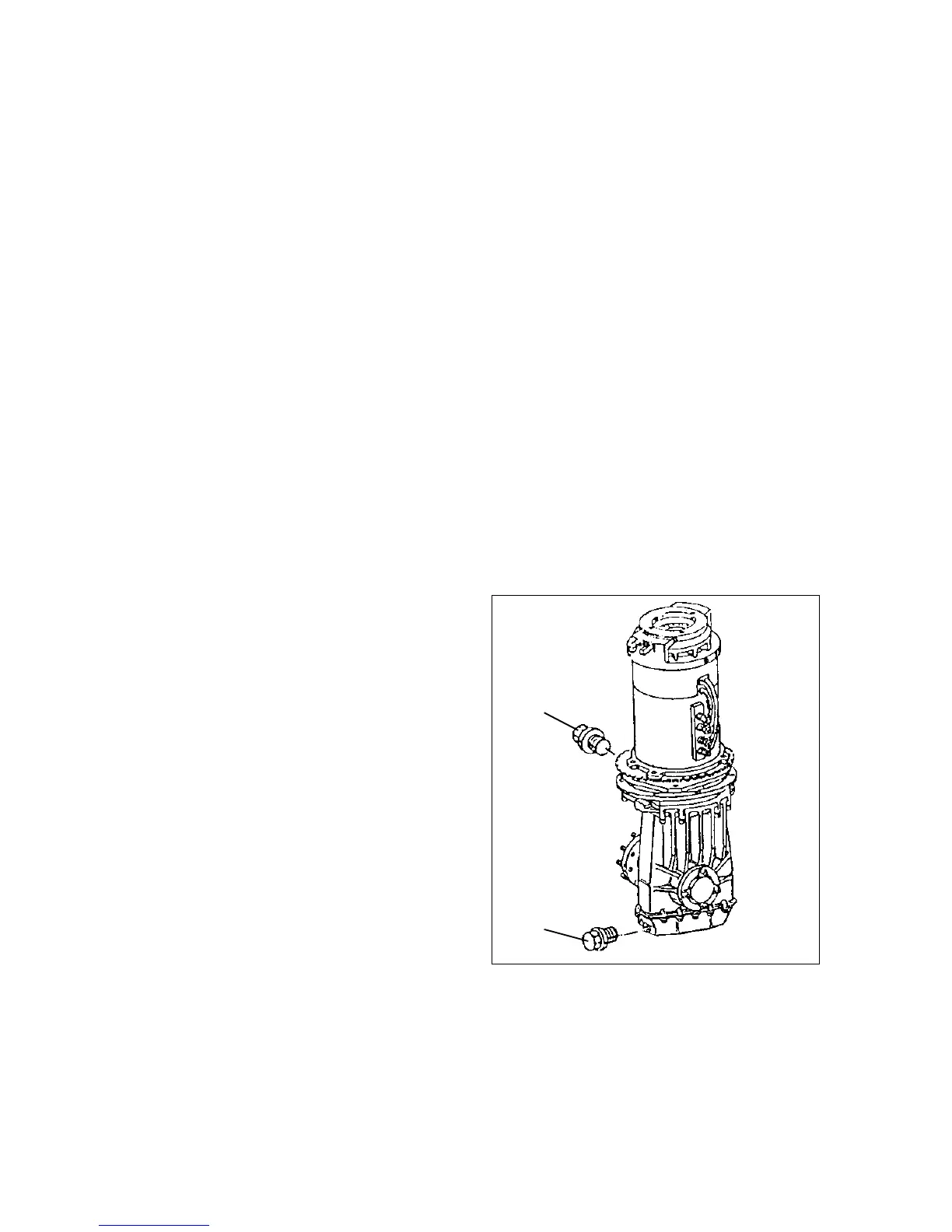

Draining the oil:

– Place an oil pan under the transmissi-

on.

– Open the oil drain plug (7) at the trans-

mission bottom and drain the oil.

Refilling oil:

– Screw in oil drain plug (7) and tighten.

– Open the oil level and filling plug (6) at

the transmission top.

– Fill with new transmission oil up to the

oil level plug opening.

– Screw in the oil level and filling plug

(6).

A

Since the waste oils must be disposed of

in accordance with the applicable envi-

ronmental protection regulations and be-

cause special tools and skills may be required for changing transmission oil, hydraulic

oil, and brake fluid as well for replacing filters, these operations should be performed

by the manufacturer’s service personnel.

6

7

Loading...

Loading...