1298.GB

C 2

3 First commissioning

3.1 Commissioning without battery

m

This operating mode is not permitted when negotiating inclines and gradients (no bra-

ke!).

A

If the truck is operated without battery, the load bearing wheel brake must be released

before commissioning.

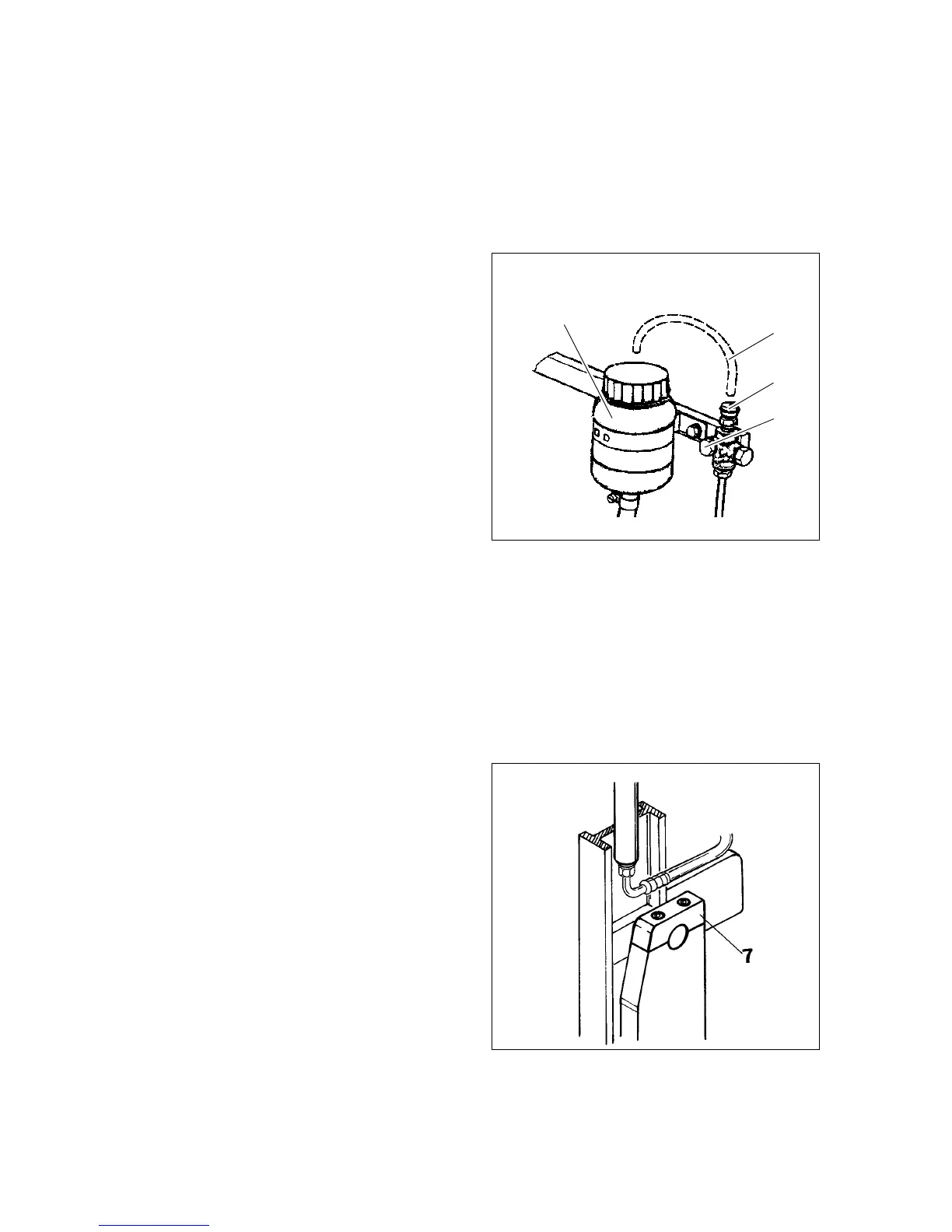

– Screw off the protective cover (5) of

the vent valve.

– Push tube (4) onto vent connection

and insert the other end of the tube

into the brake fluid reservoir (3) loca-

ted above.

f

Brake fluid is under pressure.

Danger of causticization.

– Open vent valve (6) and allow emer-

ging brake fluid to drain into the brake

fluid reservoir.

– Close vent valve and brake fluid re-

servoir.

A

The operatability of the brake system is restored after inserting the battery and after

operating the foot switch several times.

m

Test the brake deceleration.

These measures may only be performed by service engineers of the manufacturer.

3.2 Commissioning with dismounted or tilted mast

If the truck has been delivered with dismounted or tilted mast due to tall height, the

mast has to be mounted by a trained mechanic.

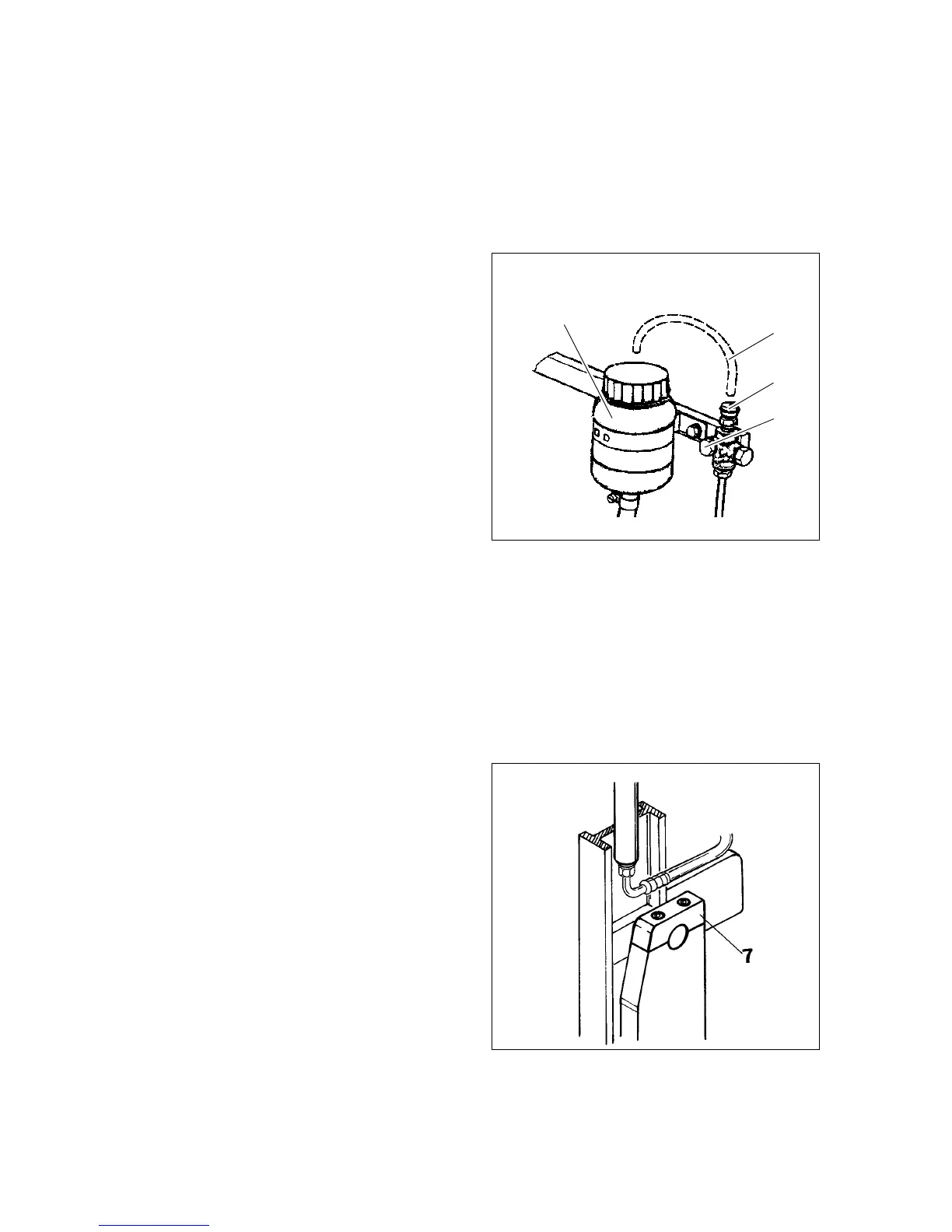

– If mast is tilted, loosen lift mast pede-

stal (7) (do not remove screws).

– Set hoist frame with suitable hoisting

equipment to a vertical position. Add

compensating sheets, if available,

and screw down mast and lifting mast

bearing.

3

4

5

6

1298.GB

C 2

3 First commissioning

3.1 Commissioning without battery

m

This operating mode is not permitted when negotiating inclines and gradients (no bra-

ke!).

A

If the truck is operated without battery, the load bearing wheel brake must be released

before commissioning.

– Screw off the protective cover (5) of

the vent valve.

– Push tube (4) onto vent connection

and insert the other end of the tube

into the brake fluid reservoir (3) loca-

ted above.

f

Brake fluid is under pressure.

Danger of causticization.

– Open vent valve (6) and allow emer-

ging brake fluid to drain into the brake

fluid reservoir.

– Close vent valve and brake fluid re-

servoir.

A

The operatability of the brake system is restored after inserting the battery and after

operating the foot switch several times.

m

Test the brake deceleration.

These measures may only be performed by service engineers of the manufacturer.

3.2 Commissioning with dismounted or tilted mast

If the truck has been delivered with dismounted or tilted mast due to tall height, the

mast has to be mounted by a trained mechanic.

– If mast is tilted, loosen lift mast pede-

stal (7) (do not remove screws).

– Set hoist frame with suitable hoisting

equipment to a vertical position. Add

compensating sheets, if available,

and screw down mast and lifting mast

bearing.

3

4

5

6

Loading...

Loading...