1298.GB

F 4

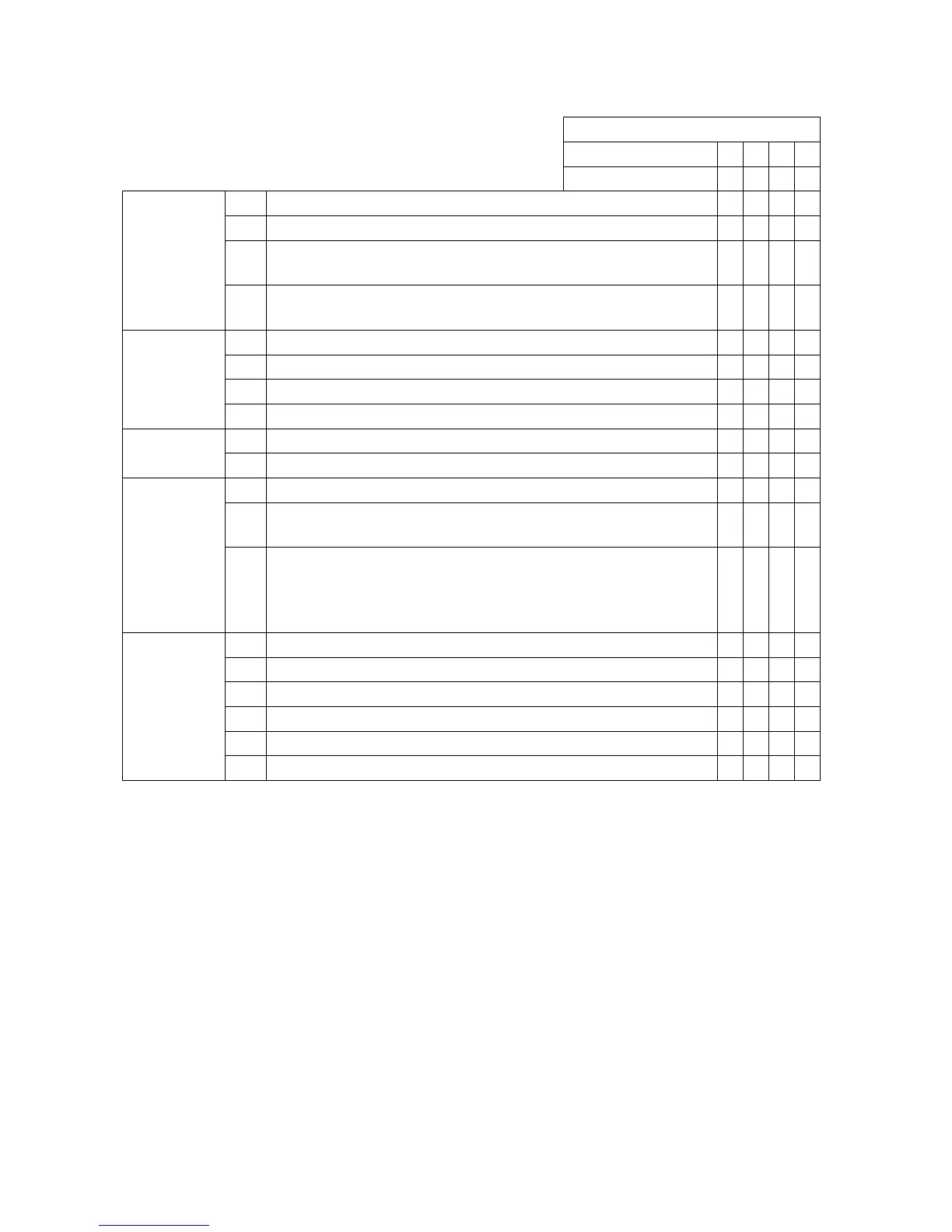

4 Maintenance checklist KMS 100

a) Wheel nuts to be first checked for tightness after approx. 100 operating hours; tighten, if

necessary.

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

d) First change after 500 operating hours

A

The maintenance intervals refer to normal service conditions.

In case of aggravated conditions, the intervals must be reduced as required.

Maintenance intervals

Standard = t WMMM

13612

Chassis/

superstruc-

ture:

1.1 Check all load bearing elements for damage t

1.2 Check all bolted connections t

1.3 Check Operator platform for correct functioning and dama-

ges

t

1.4 Check marking locations, identification labels and warning

signs for readability; replace if necessary

t

Drive unit: 2.1 Grease seating between drive motor and transmission t

2.2 Check the transmission for noises and leakage t

2.3 Check the transmission oil level t

2.4 Change the gear oil t

Wheels: 3.1 Check for wear and damage t

3.2 Check seating and fixing a) t

Steering: 4.1 Lubricate steering pinion and ring gear at the transmission t

4.2 Check the wheel position indicator for correct functioning

and alignment

t

4.3 Check the distance between guide rollers and rail guide on

the entire length of the rails. The play between the two gui-

de rollers should be 0 to 5 mm (measured across the axle).

Rollers must not jam.

t

Brake

system:

5.1 Check for correct function and adjustment t

5.2 Check the brake linings for wear t

5.3 Check the brake linkage; adjust and grease, if necessary t

5.4 Check the brake lines, connections and brake fluid level t

5.5 Check the brake fluid t

5.6 Change the brake fluid t

1298.GB

F 4

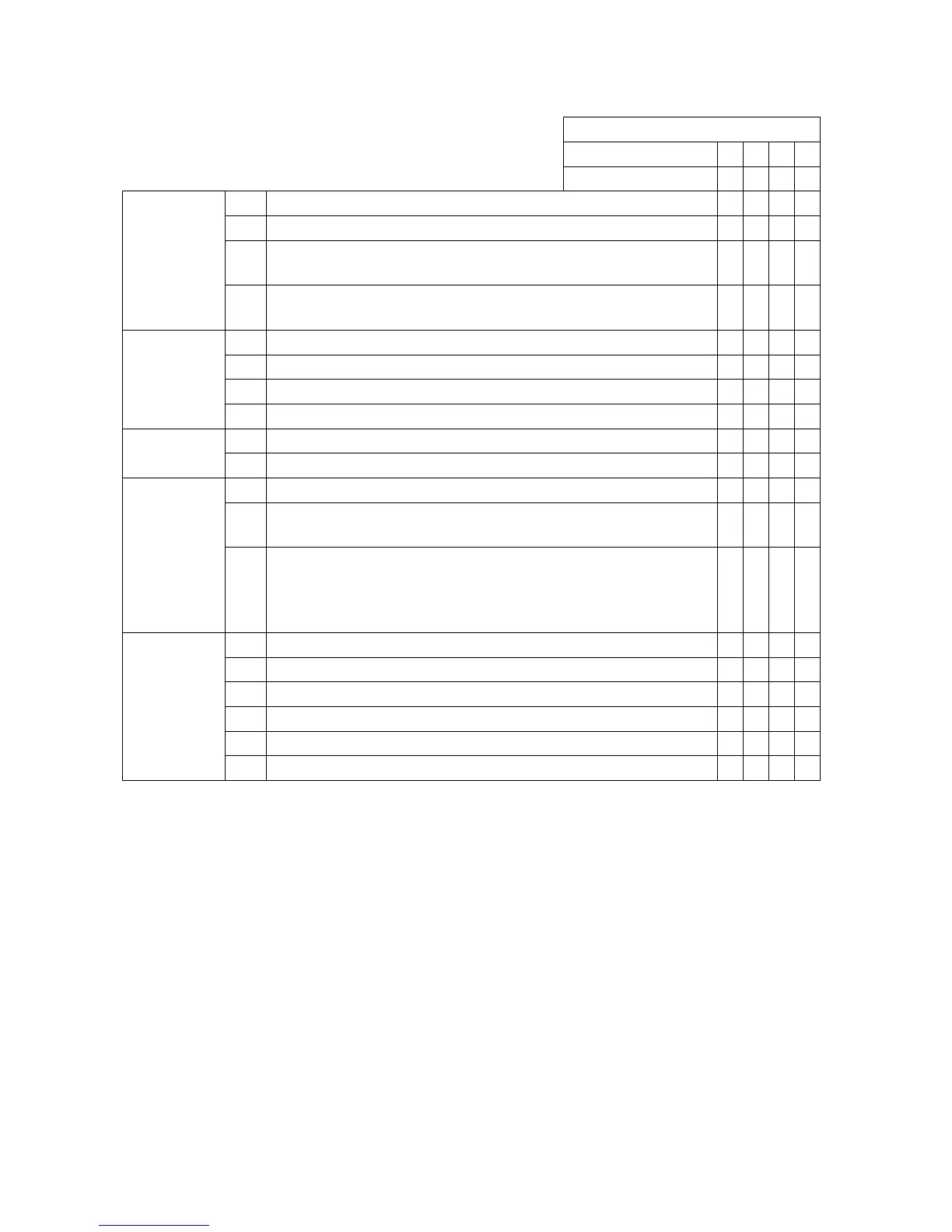

4 Maintenance checklist KMS 100

a) Wheel nuts to be first checked for tightness after approx. 100 operating hours; tighten, if

necessary.

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

d) First change after 500 operating hours

A

The maintenance intervals refer to normal service conditions.

In case of aggravated conditions, the intervals must be reduced as required.

Maintenance intervals

Standard = t WMMM

13612

Chassis/

superstruc-

ture:

1.1 Check all load bearing elements for damage t

1.2 Check all bolted connections t

1.3 Check Operator platform for correct functioning and dama-

ges

t

1.4 Check marking locations, identification labels and warning

signs for readability; replace if necessary

t

Drive unit: 2.1 Grease seating between drive motor and transmission t

2.2 Check the transmission for noises and leakage t

2.3 Check the transmission oil level t

2.4 Change the gear oil t

Wheels: 3.1 Check for wear and damage t

3.2 Check seating and fixing a) t

Steering: 4.1 Lubricate steering pinion and ring gear at the transmission t

4.2 Check the wheel position indicator for correct functioning

and alignment

t

4.3 Check the distance between guide rollers and rail guide on

the entire length of the rails. The play between the two gui-

de rollers should be 0 to 5 mm (measured across the axle).

Rollers must not jam.

t

Brake

system:

5.1 Check for correct function and adjustment t

5.2 Check the brake linings for wear t

5.3 Check the brake linkage; adjust and grease, if necessary t

5.4 Check the brake lines, connections and brake fluid level t

5.5 Check the brake fluid t

5.6 Change the brake fluid t

Loading...

Loading...