F 5

1298.GB

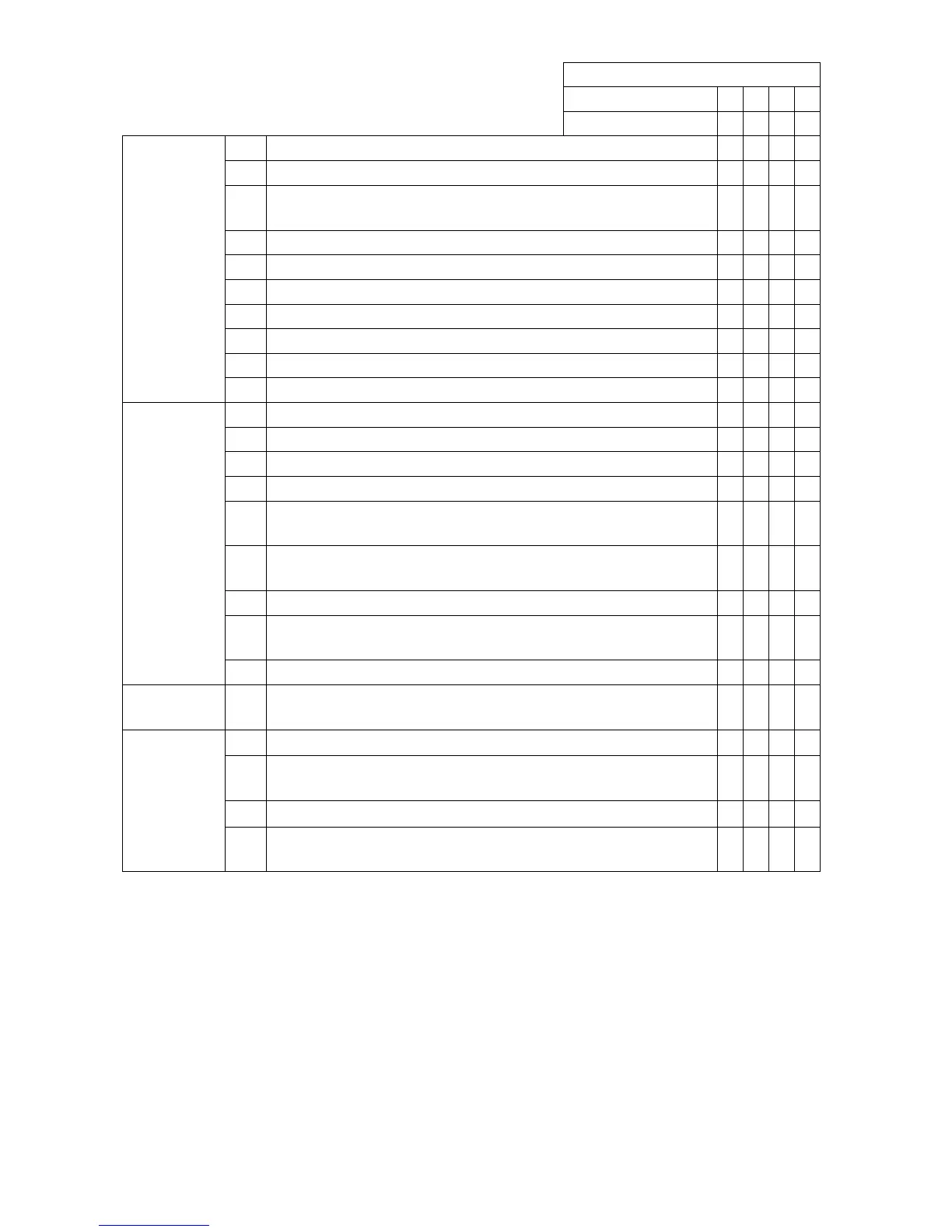

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

d) First change after 500 operating hours

p) Replace hydraulic hoses after 6 years of operation

Maintenance intervals

Standard = t WMMM

13612

Hydraulic

system:

6.1 Check function t

6.2 Check all connections for leakage and damage b) t

6.3 Check hydraulic cylinders for leakage, damage and secure

attachment

t

6.4 Check the oil level t

6.5 Check the hose line for correct functioning and damage t

6.6 Check breather and vent filters at the hydraulic reservoir t

6.7 Change breather and vent filters at the hydraulic reservoir t

6.8 Change hydraulic oil and filter insert d) t

6.9 Check the pressure relief valves for correct functioning t

6.10 Check hydraulic lines for tightness and damage p) t

Electrical

system.

7.1 Check the discharge of static electricity t

7.2 Check function t

7.3 Check all cables for secure connection and damage t

7.4 Check the cable runs for correct functioning and damage t

7.5 Check the warning facilities and safety switches for correct

functioning

t

7.6 Check all sensors for secure attachment, damage, cleanli-

ness and correct functioning

t

7.7 Check the instrument and indicators for correct functioning t

7.8 Check contactors and relays, replace wearing parts, if ne-

cessary

t

7.9 Check the fuses for correct amperage t

Electric

motors:

8.2 Check the motor for secure attachment t

Battery: 9.1 Check acid density, acid level and cell voltage t

9.2 Check the terminals for secure attachment and apply pole

grease

t

9.3 Clean battery connections, check for tight fit t

9.4 Check the battery cables for damage and replace, if neces-

sary

t

F 5

1298.GB

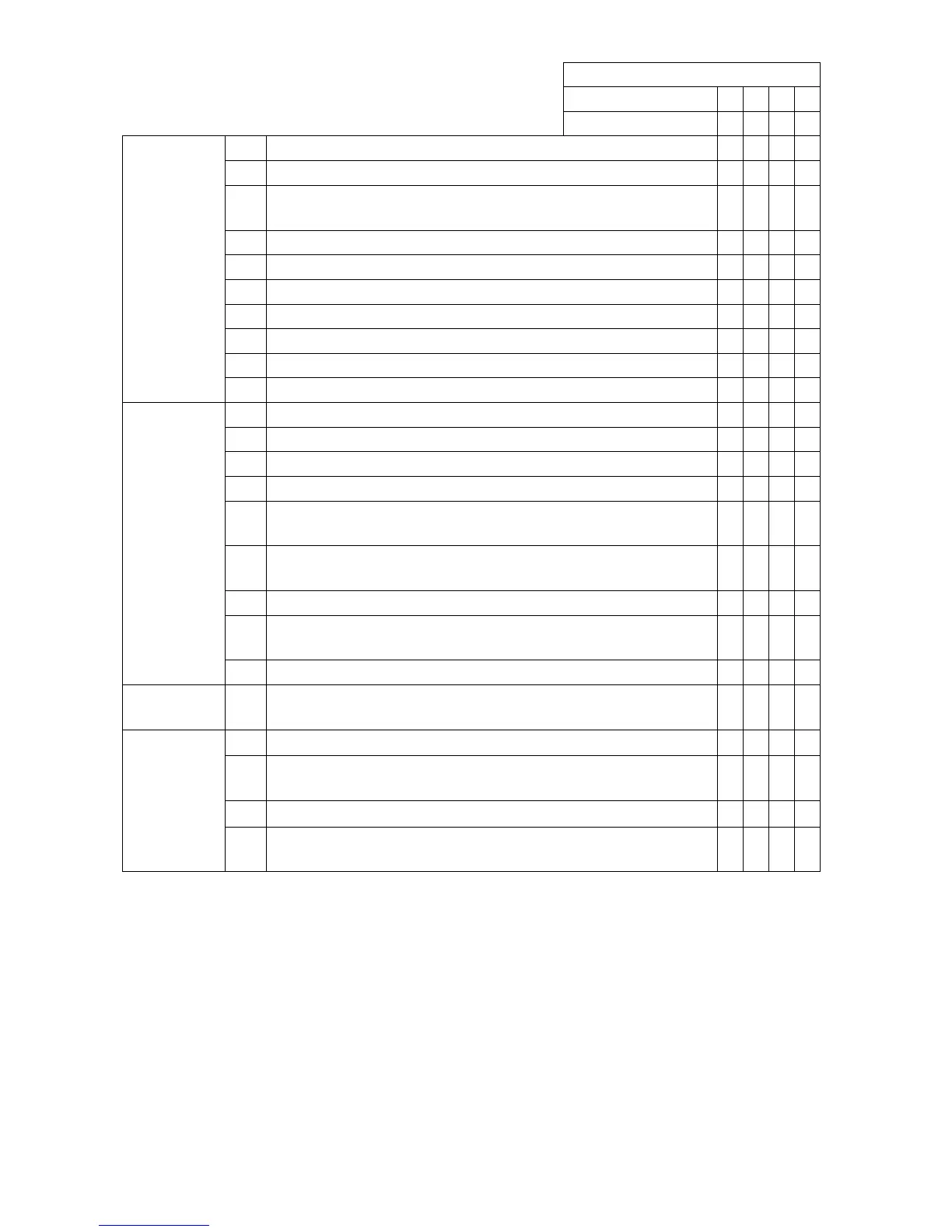

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

d) First change after 500 operating hours

p) Replace hydraulic hoses after 6 years of operation

Maintenance intervals

Standard = t WMMM

13612

Hydraulic

system:

6.1 Check function t

6.2 Check all connections for leakage and damage b) t

6.3 Check hydraulic cylinders for leakage, damage and secure

attachment

t

6.4 Check the oil level t

6.5 Check the hose line for correct functioning and damage t

6.6 Check breather and vent filters at the hydraulic reservoir t

6.7 Change breather and vent filters at the hydraulic reservoir t

6.8 Change hydraulic oil and filter insert d) t

6.9 Check the pressure relief valves for correct functioning t

6.10 Check hydraulic lines for tightness and damage p) t

Electrical

system.

7.1 Check the discharge of static electricity t

7.2 Check function t

7.3 Check all cables for secure connection and damage t

7.4 Check the cable runs for correct functioning and damage t

7.5 Check the warning facilities and safety switches for correct

functioning

t

7.6 Check all sensors for secure attachment, damage, cleanli-

ness and correct functioning

t

7.7 Check the instrument and indicators for correct functioning t

7.8 Check contactors and relays, replace wearing parts, if ne-

cessary

t

7.9 Check the fuses for correct amperage t

Electric

motors:

8.2 Check the motor for secure attachment t

Battery: 9.1 Check acid density, acid level and cell voltage t

9.2 Check the terminals for secure attachment and apply pole

grease

t

9.3 Clean battery connections, check for tight fit t

9.4 Check the battery cables for damage and replace, if neces-

sary

t

Loading...

Loading...