1298.GB

F 6

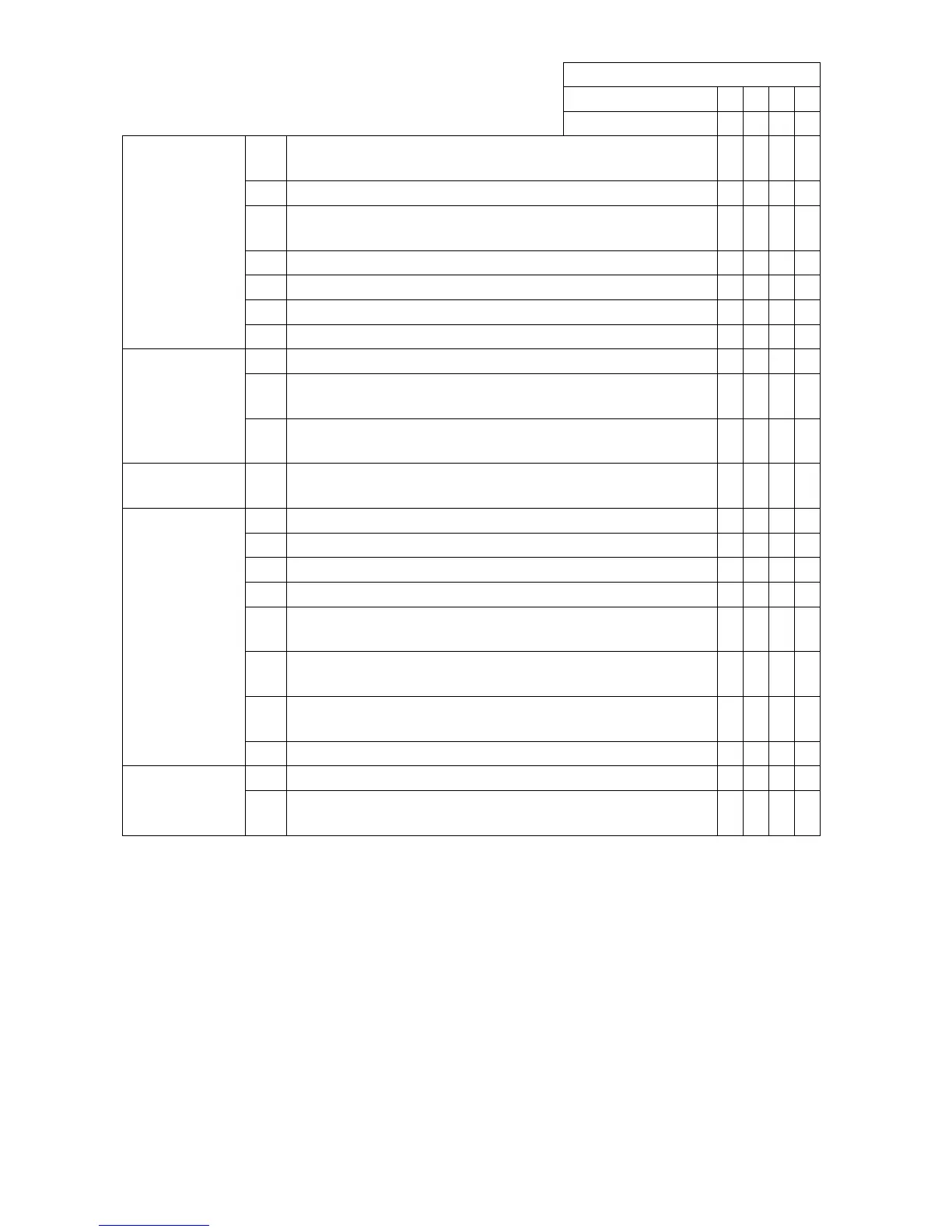

j) Chain to be first checked after approx. 100 operating hours; tighten, if necessary.

e) IG: induction-guided trucks

Maintenance intervals

Standard = t WMMM

13612

Lifting device 10.1 Apply grease to rollers and side run areas of idler pulleys

in the hoist frame profiles.

t

10.2 Check secure attachment of hoist frame t

10.3 Check hoisting chains and chain guide for wear; adjust

and grease j)

t

10.4 Visual check of rollers, slide pieces and stops t

10.5 Check hoisting frame seatings t

10.7 Check fork tines and fork carrier for wear and damage t

10.8 Lubricate lubricating points of the chain rollers t

Attachments: 11.1 Check function t

11.2 Check secure attachment at the device and supporting

elements

t

11.3 Check seatings, guides and stops for wear and damage;

apply grease

t

Lubrication

service:

12.1 Grease truck according to lubrication plan t

General mea-

surements:

13.1 Check electrical system for short to ground t

13.2 Check driving speed and braking distance t

13.3 Check lifting and lowering speed t

13.4 Check safety facilities and switch-off devices t

13.5 IG: Check amperage of guide wire; re-adjust,

if necessary e)

t

13.6 Check driving behavior on IG wire and maximum devia-

tion; re-adjust, if necessary e)

t

13.7 Check track-in and driving behaviour on the IG wire

during aisle track-in e)

t

13.8 Check IG emergency STOP function e) t

Demonstrati-

on:

14.1 Perform a trial run under a nominal load t

14.2 Upon completion of servicing operations, demonstrate

the truck to the person responsible

t

1298.GB

F 6

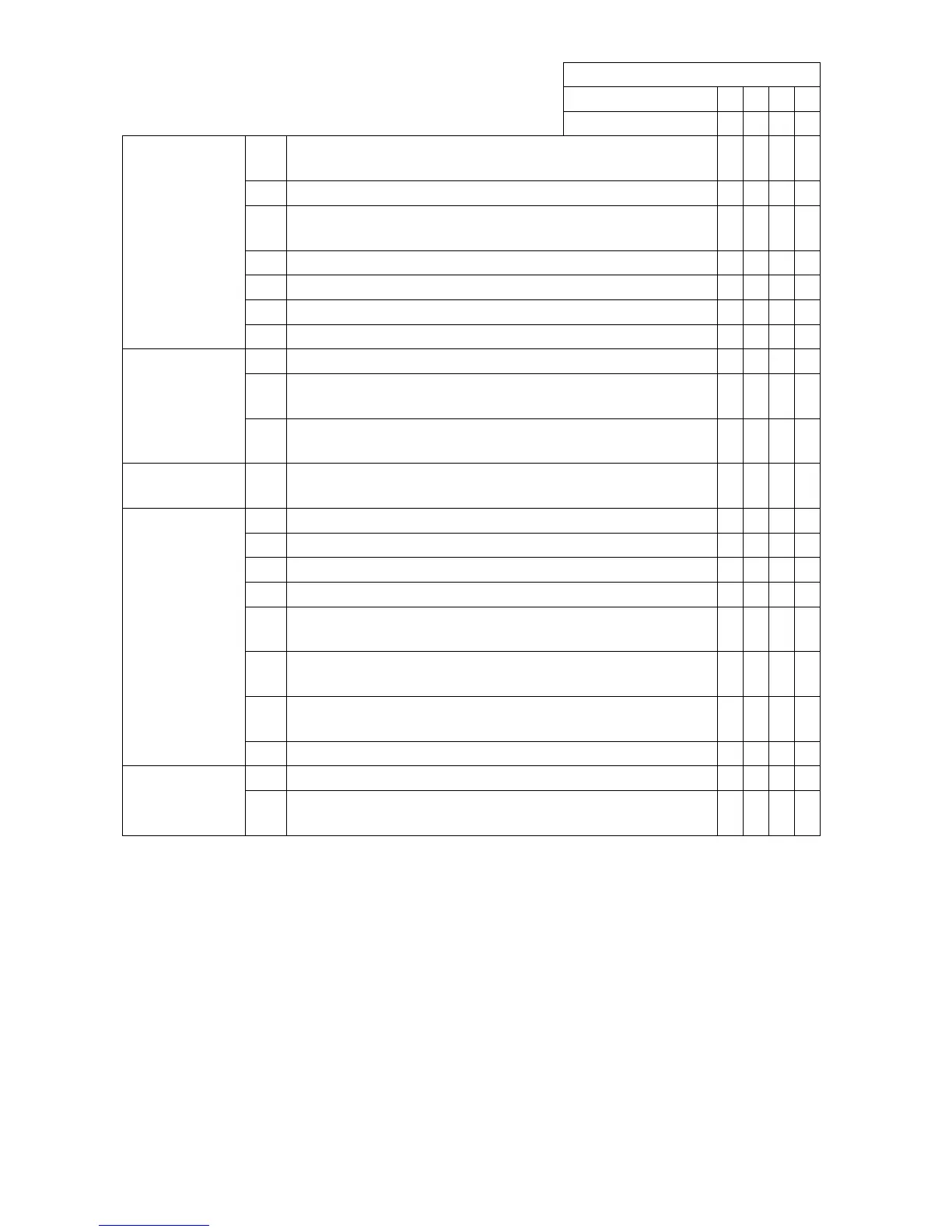

j) Chain to be first checked after approx. 100 operating hours; tighten, if necessary.

e) IG: induction-guided trucks

Maintenance intervals

Standard = t WMMM

13612

Lifting device 10.1 Apply grease to rollers and side run areas of idler pulleys

in the hoist frame profiles.

t

10.2 Check secure attachment of hoist frame t

10.3 Check hoisting chains and chain guide for wear; adjust

and grease j)

t

10.4 Visual check of rollers, slide pieces and stops t

10.5 Check hoisting frame seatings t

10.7 Check fork tines and fork carrier for wear and damage t

10.8 Lubricate lubricating points of the chain rollers t

Attachments: 11.1 Check function t

11.2 Check secure attachment at the device and supporting

elements

t

11.3 Check seatings, guides and stops for wear and damage;

apply grease

t

Lubrication

service:

12.1 Grease truck according to lubrication plan t

General mea-

surements:

13.1 Check electrical system for short to ground t

13.2 Check driving speed and braking distance t

13.3 Check lifting and lowering speed t

13.4 Check safety facilities and switch-off devices t

13.5 IG: Check amperage of guide wire; re-adjust,

if necessary e)

t

13.6 Check driving behavior on IG wire and maximum devia-

tion; re-adjust, if necessary e)

t

13.7 Check track-in and driving behaviour on the IG wire

during aisle track-in e)

t

13.8 Check IG emergency STOP function e) t

Demonstrati-

on:

14.1 Perform a trial run under a nominal load t

14.2 Upon completion of servicing operations, demonstrate

the truck to the person responsible

t

Loading...

Loading...