MasterMig 353, 355

Operating manual- EN

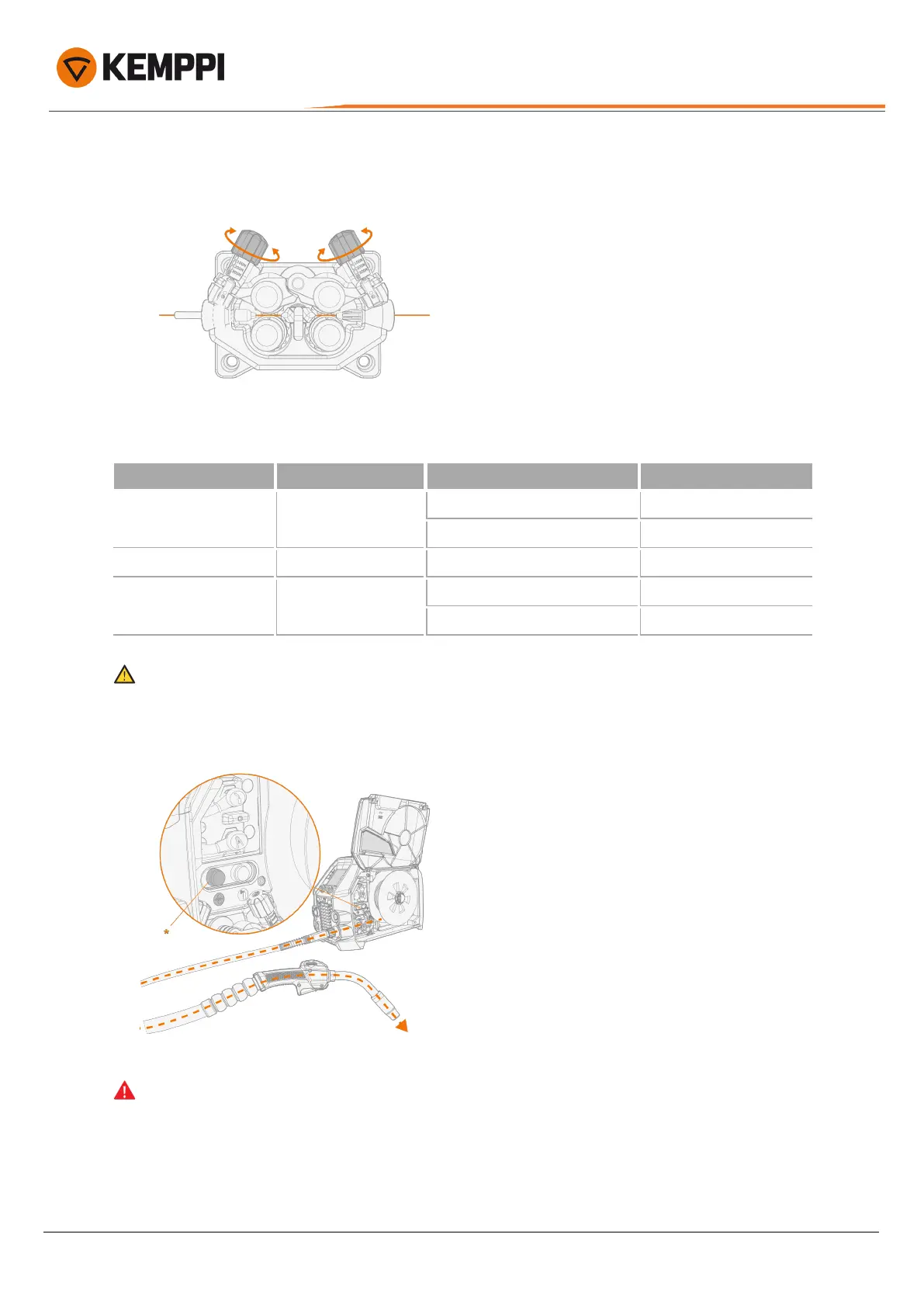

7. Adjust the pressure of the feed rolls with the pressure adjustment wheels. The pressure is the same for both feed

roll pairs.

The graduated scales on the pressure handle indicate the pressure applied to the feed rolls. Adjust the pressure of the

feed rolls according to the table below.

Filler wire material Feed roll profile* Filler wire diameter (mm) Adjustment (x100N)

Fe/Ss solid

V-groove 0.8-1.0 1.5-2.0

≥ 1.2 2.0−2.5

MC/FC

V-groove, knurled ≥ 1.2 1.0−2.0

Al

U-groove 1.0 0.5−1.0

1.2 1.0−1.5

Excessive pressure flattens the filler wire and may damage coated or cored filler wires. Excessive pressure also unne-

cessarily wears the feed rolls and increases gearbox load.

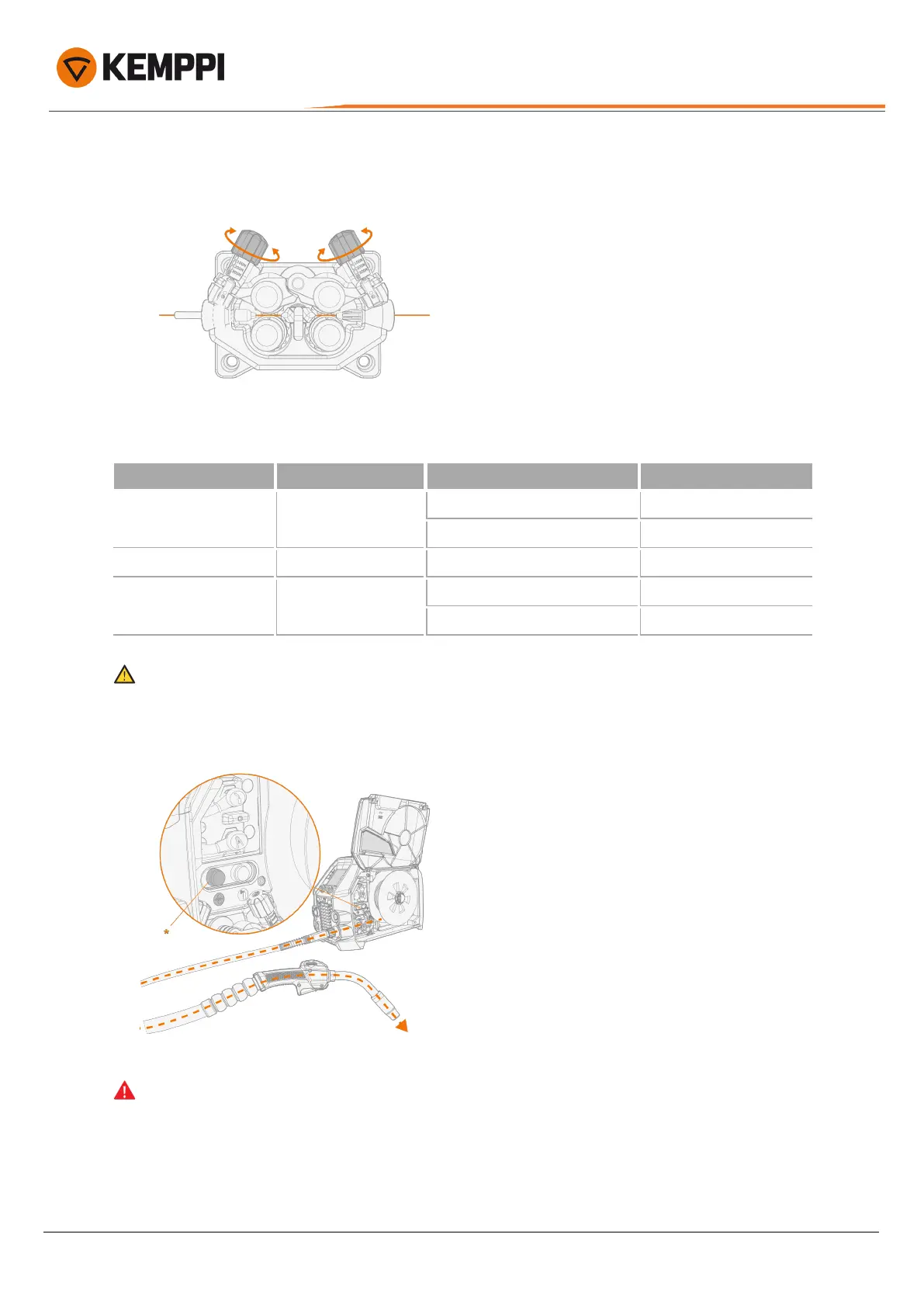

8. Press the wire inch button (*) to drive the filler wire into the welding gun. Stop when the wire reaches the welding

gun's contact tip. The wire feed speed can be adjusted in the control panel.

Watch out for the wire when it reaches the contact tip and exits the gun.

© Kemppi

23

1921960 / 2217

Loading...

Loading...