MasterMig 353, 355

Operating manual- EN

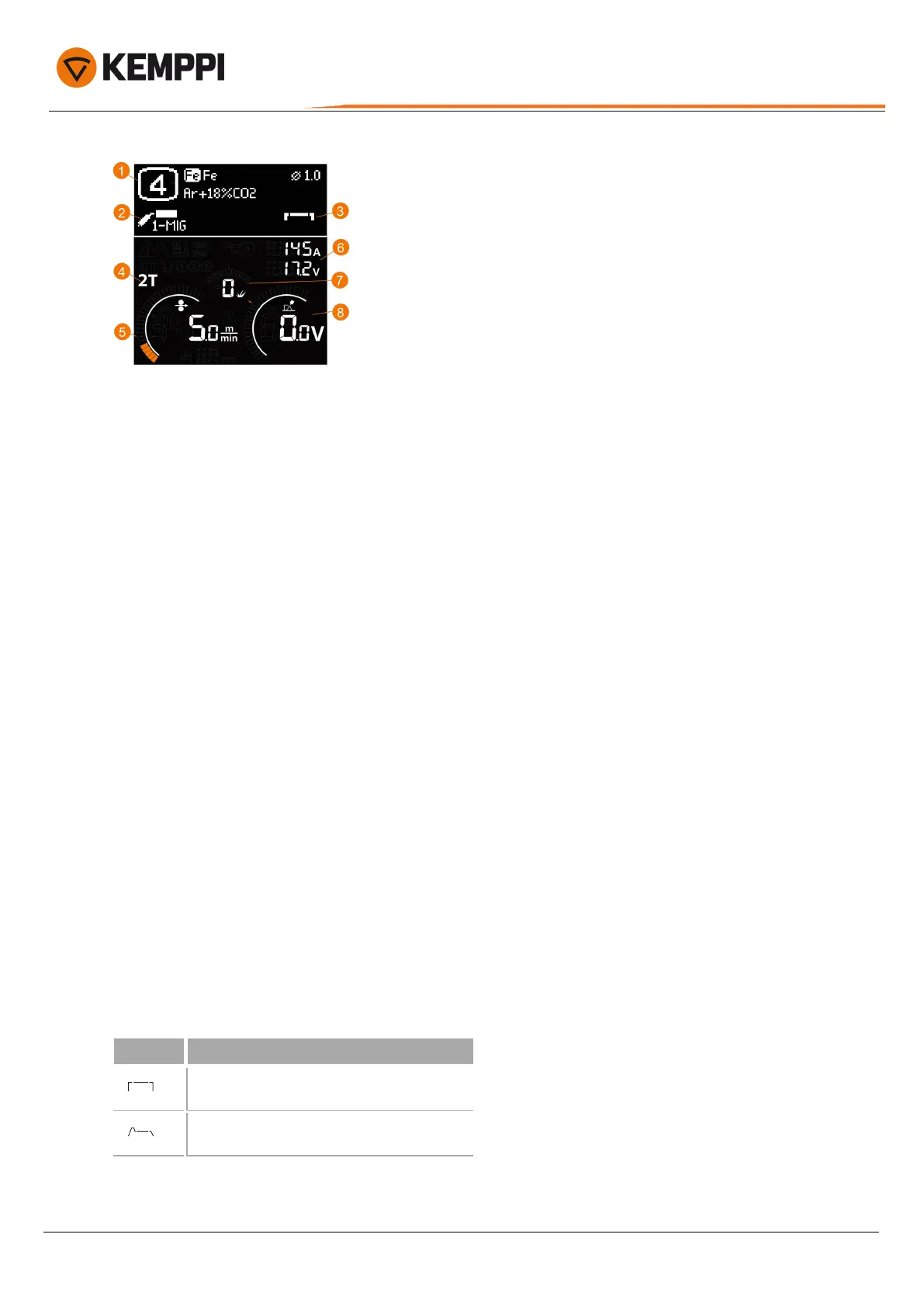

1. Memory channel (and filler wire and shielding gas settings, if set)

2. Active welding process

3. Applied welding functions*

4. Applied trigger logic function

5. Wire feed speed

>> The value range is defined by the active welding program, step 0.1, default = 5.0 m/min

6. Current and voltage

7. Dynamics

>> Controls the short circuit behavior of the arc. The lower the value the softer the arc, the higher the value the

rougher the arc. Value range: -9 ... +9, default = 0

>> With MAX process a corresponding MAX parameter adjustment is displayed

8. Welding voltage

>> With 1-MIG process voltage fine tuning is displayed

>> With MAX process a corresponding MAX parameter adjustment is displayed.

Control knob functions

Left control knob:

• Manual MIG: Wire feed speed adjustment

• 1-MIG: Wire feed speed adjustment

• Pulse MIG: Wire feed speed adjustment

• DPulse MIG: Wire feed speed adjustment and switching between pulse levels with the control knob button

• TIG/MMA: Welding current adjustment.

Right control knob:

• Manual MIG: Welding voltage and dynamics adjustment

• 1-MIG:Dynamics adjustment and fine tuning of welding voltage and switching between the adjustments with the

control knob button

• Pulse MIG: Fine tuning of welding voltage

• DPulse MIG: Fine tuning of welding voltage

• MMA:Dynamics adjustment.

* Applied welding functions

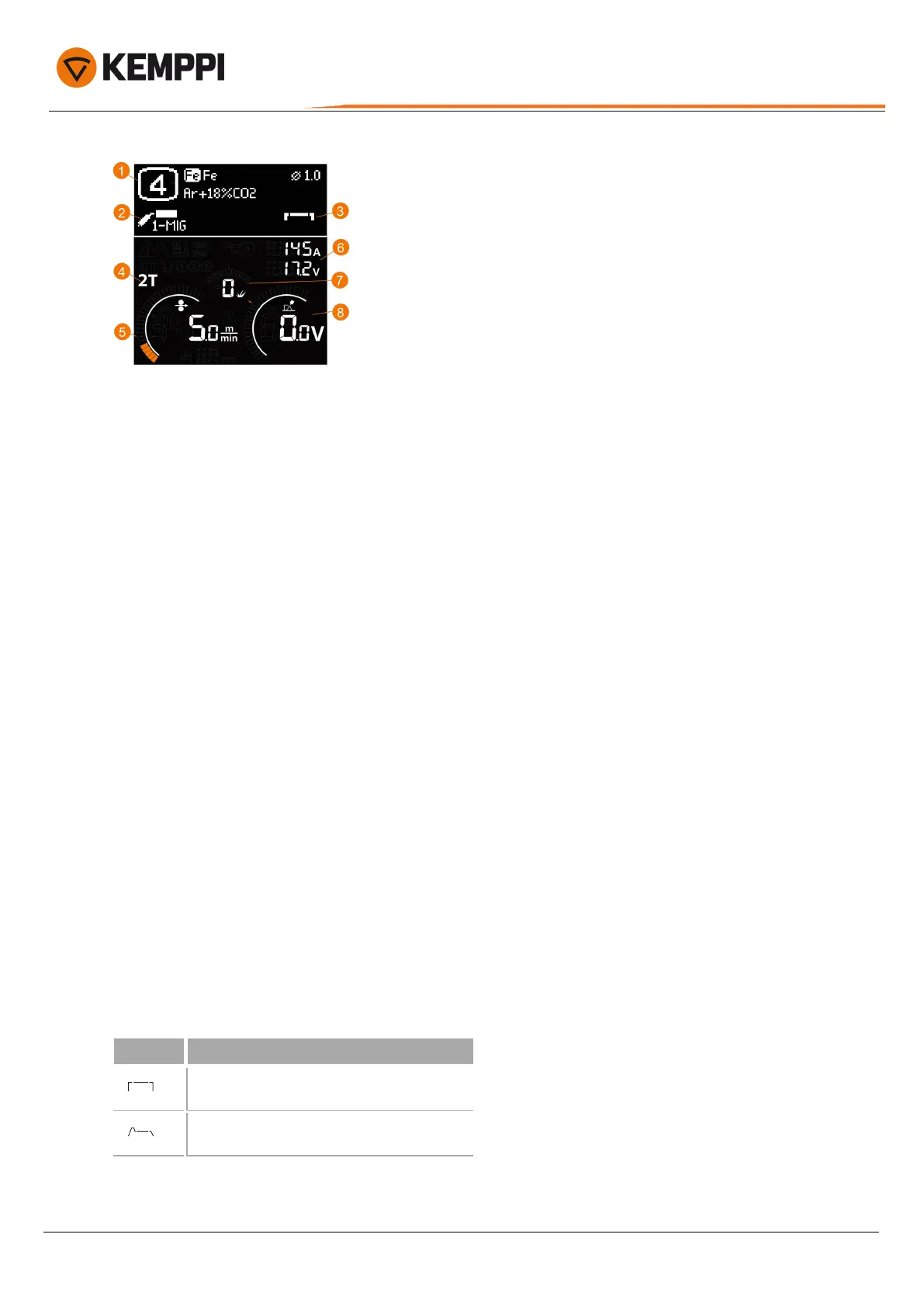

Graph Description

Hot start, Powerlog and crater fill OFF.

Hot start and crater fill ON.

© Kemppi

36

1921960 / 2217

Loading...

Loading...