KICstart Version 1.1.0.x

KICstart User Manual 49

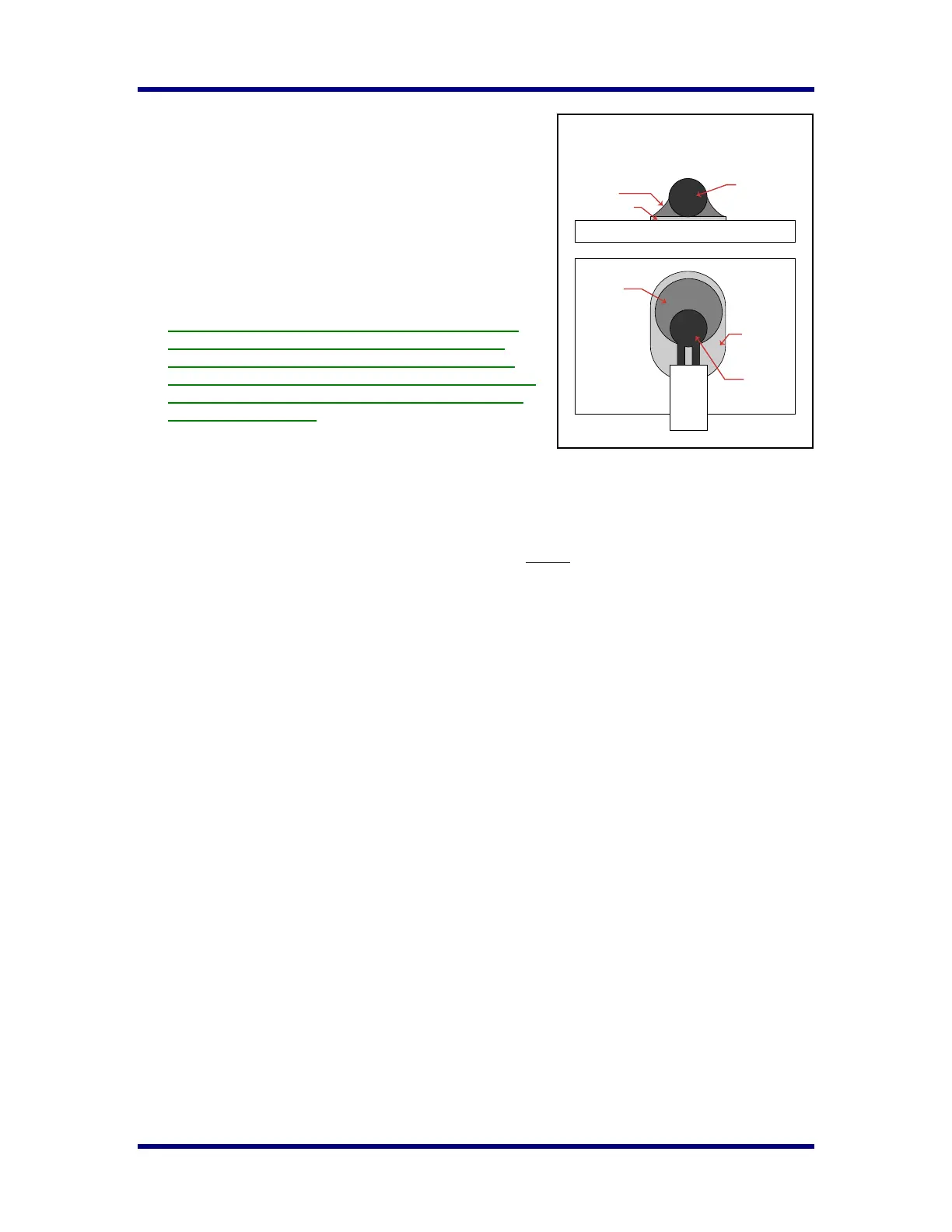

High Temperature Solder

Do not attempt to attach the TC by melting solder into the spot

and then shoving in the bead. Place the TC bead on the

attachment surface and heat both evenly with the soldering iron.

Make sure your iron is set to achieve temperatures over the

solder melting point. For the solder KIC provides 300 C should

be sufficient. Then touch the solder to the heated TC bead and

let the heat from the TC bead melt the solder. This method

gives you superior wetting and a stronger solder attachment to

the pad or lead.

Be sure and remove any residual eutectic solder before

applying the high temperature solder. If the eutectic

solder is not removed, the tension of the thermocouple

wire may lift the component as soon as the eutectic solder

reaches it’s melting point, which is a lower temperature

than high temp. solder.

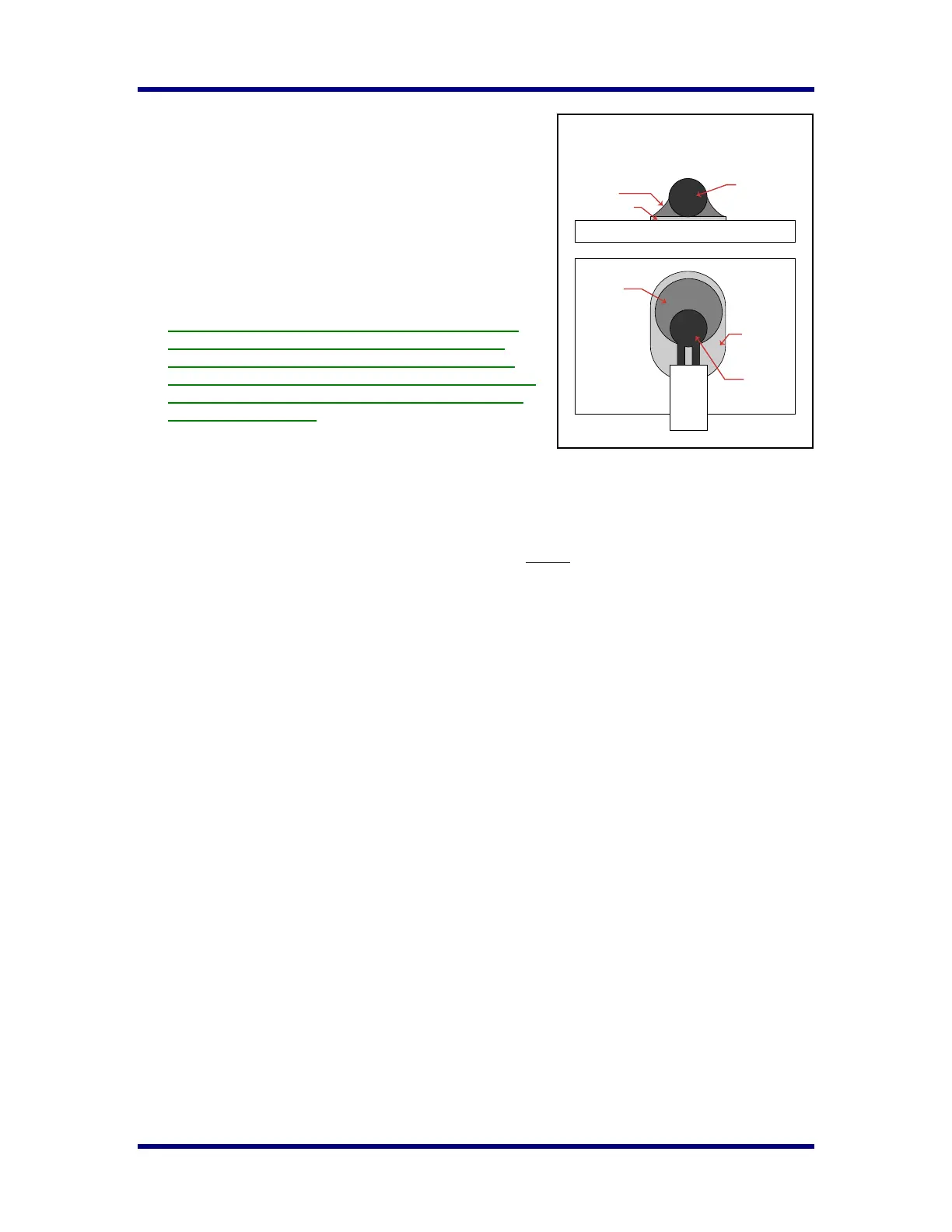

Your temperature reading will come from the first point of contact between the two wires leading from the

TC. To insure accurate readings, it is critical to carefully separate the two wires all the way up to the TC

bead after soldering.

High temperature solder is an efficient heat conductor, so if a tiny bit

gets between the TC bead and the

lead or pad; you will still get an accurate reading. However, too much solder at the measurement point will

increase the heat capacity of the TC and cause your peak temperature measurement to read low.

Thermocouple

Bead

High Temp

Solder

Solder Pad

Solder

Attachment Method

Board

Thermocouple

Bead

Solder Pad

Board

High Temp

Solder

Loading...

Loading...