ANTI-FREEZE

* At 760 mmHg pressure (atmospher-

ic). A higher boiling point is obtained

by using a radiator pressure cap.

This tractor is lled with 50% of eth-

ylene glycol at factory.

If the anti-freeze has been replaced

by tap water later on, the coolant can

be frozen, leading to damage to the

cylinder and radiator when the ambi-

ent temperature is below 0

℃.

Therefore, make sure to change

water into anti-freeze before winter

season comes.

When changing the anti-freeze with

one of another type, ush the cooling

system several times and contact a

professional for the mixture ratio.

Vol. %

Anti-freeze

Freezing

Point

Boiling

Point*

°F

°C °F °C

40

50

-12

-34

-24

-37

222

226

106

108

The temperatures shown on the

left are industry standards that

necessitate a minimum glycol

content in the concentrated anti-

freeze.

When the coolant level drops

due to evaporation, add water

only. In case of leakage, add an-

ti-freeze and water in the speci-

ed mixing ratio.

Anti-freeze absorbs moisture.

Keep unused anti-freeze in a

tightly sealed container.

Do not use radiator cleaning

agents when anti-freeze has

been added to the cooling water.

(Anti-freeze contains an anti-

corrosive agent, which will react

with the radiator cleaning agent

forming sludge which will affect

the engine parts)

NOTE

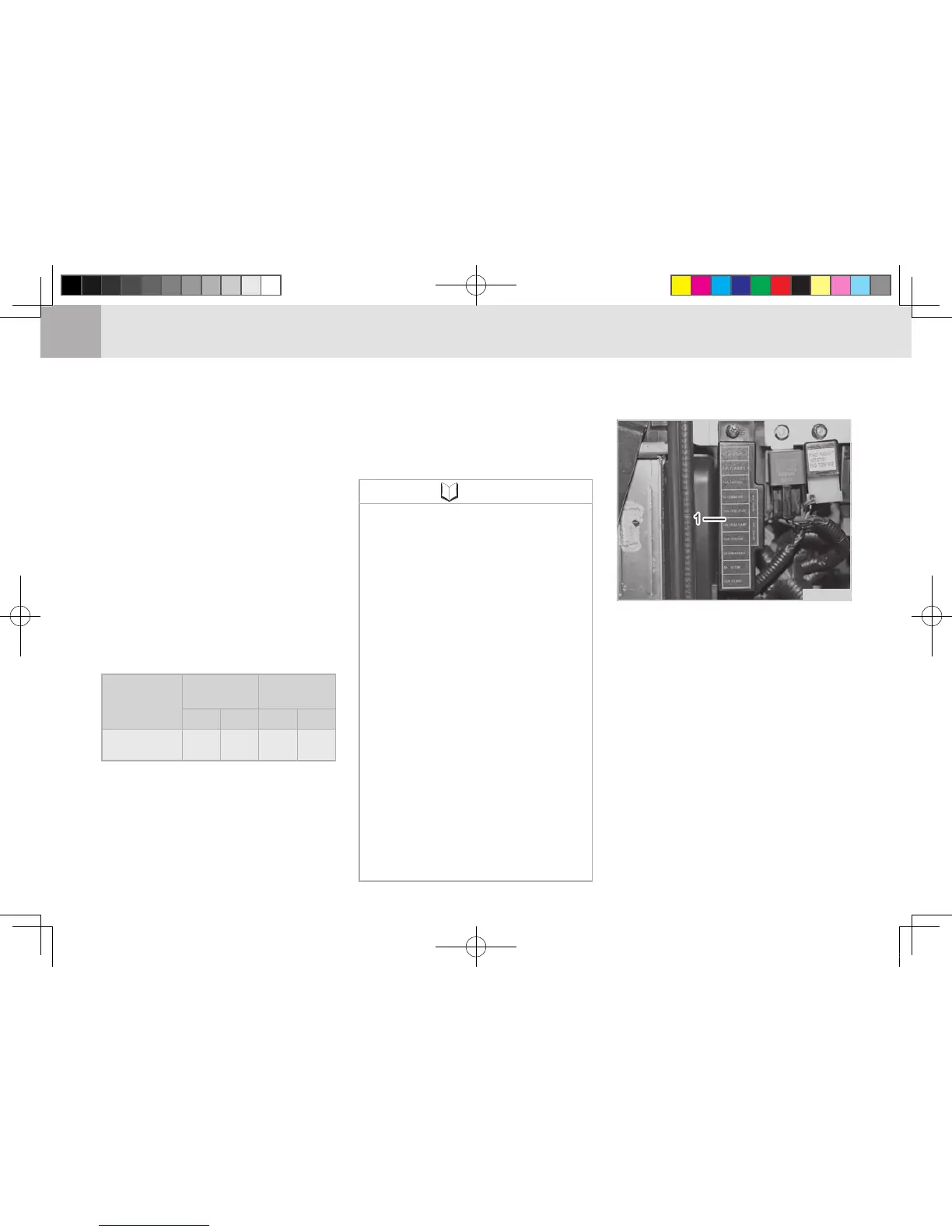

Fuses protect the tractor electrical

system from potential damage. A

blown fuse indicates that there is an

overload or short somewhere in the

electrical system.

(1) Fuse Box

M46O735A

REPLACING FUSE (AN)

Loading...

Loading...