FlexStat 11 Operation Guide, Rev. R

(Advanced) CO

2

Sensor (and DCV)

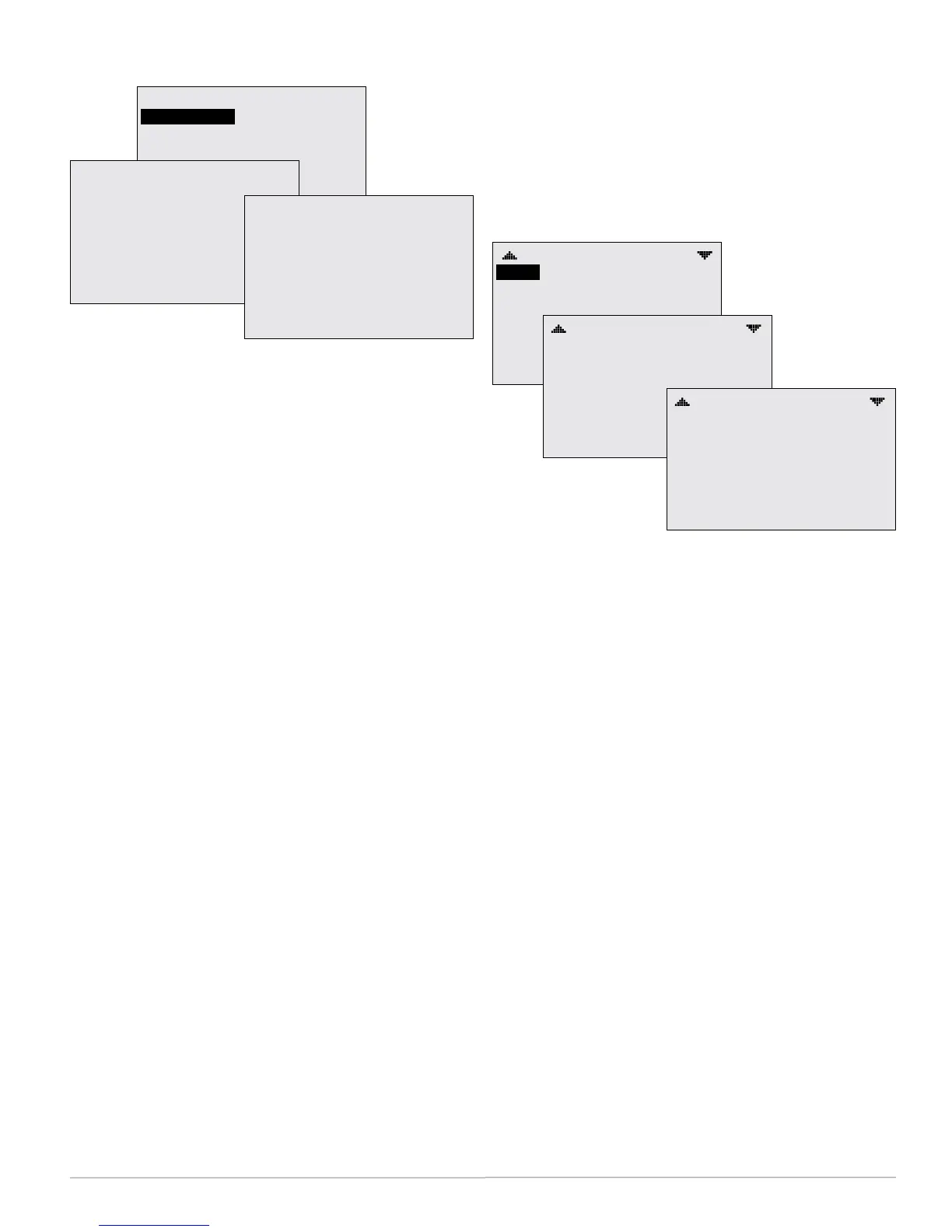

CO2 SENSOR

SENSOR INFO

CALIBRATION

CO2 SENSOR INFO

MODEL: T6615

SUB VOL: A15

SW DATE: 090217

S/N: AB00011759

CO2: 873

ELEVATION: 0

STATUS: NORMAL

CO2 CALIBRATION

ELEVATION: 0

REFERENCE GAS: 300

MODE: MONITOR

CO2: 1067

STATUS: NORMAL

CAL TIME: 00:00

CO

2

Sensor Setup and Information

NOTE: Set the desired CO

2

setpoint under the

Setpoints menu. See Setpoints on page 25.

For maximum sensor accuracy, enter the elevation

(altitude)abovesealevel of the building’s location.

(The default value is 0.) Elevation for any particular

location can be found at such sources as www.earth-

tools.org. (For very tall buildings, the upper oors

would have a higher elevation than lower oors.)

After power is rst applied or the FlexStat is restart-

ed, the sensor goes through a warm-upfor approxi-

mately half a minute. During the time the sensor

count will be 0 ppm and the Status line will display

WARMUP instead of NORMAL.

The sensoranditsrmware are identied by the

model, the compilation subvolume (SUB VOL), com-

pilation date (SW DATE in yymmdd format), and

serial number.

NOTE: With the CO

2

sensor enabled, a trend log is

automatically generated. See (Advanced)

Trend Logs on page 20.

The BAC-13xxxx models do not have a calibration

with gas option. It uses Automatic Background

Logic, or ABC Logic

™

, a patented self-calibration

technique designed to be used inapplicationswhere

concentrationswilldroptooutsideambientcondi-

tions(approximately400ppm)atleastthreetimes

ina14dayperiod, typically during unoccupied

periods.

The BAC-14xxxx models have a calibrationoption

forapplyinggastothesensor for maintaining maxi-

mum accuracy. These models have a dual channel

sensor (a CO

2

channel measures gas concentration,

and a reference channel measures the sensor signal

intensity). Self-calibrations are performed approxi-

mately every 24 hours using the reference channel.

During the self-calibration the sensor PPM reading is

frozen and will not react to changing CO

2

.

For instructionsoncalibratingthe BAC-14xxxx

models withgas, see the CO

2

Sensor Calibration sec-

tion in the FlexStatApplicationGuide.

DCV (Demand Control Ventilation) Setup

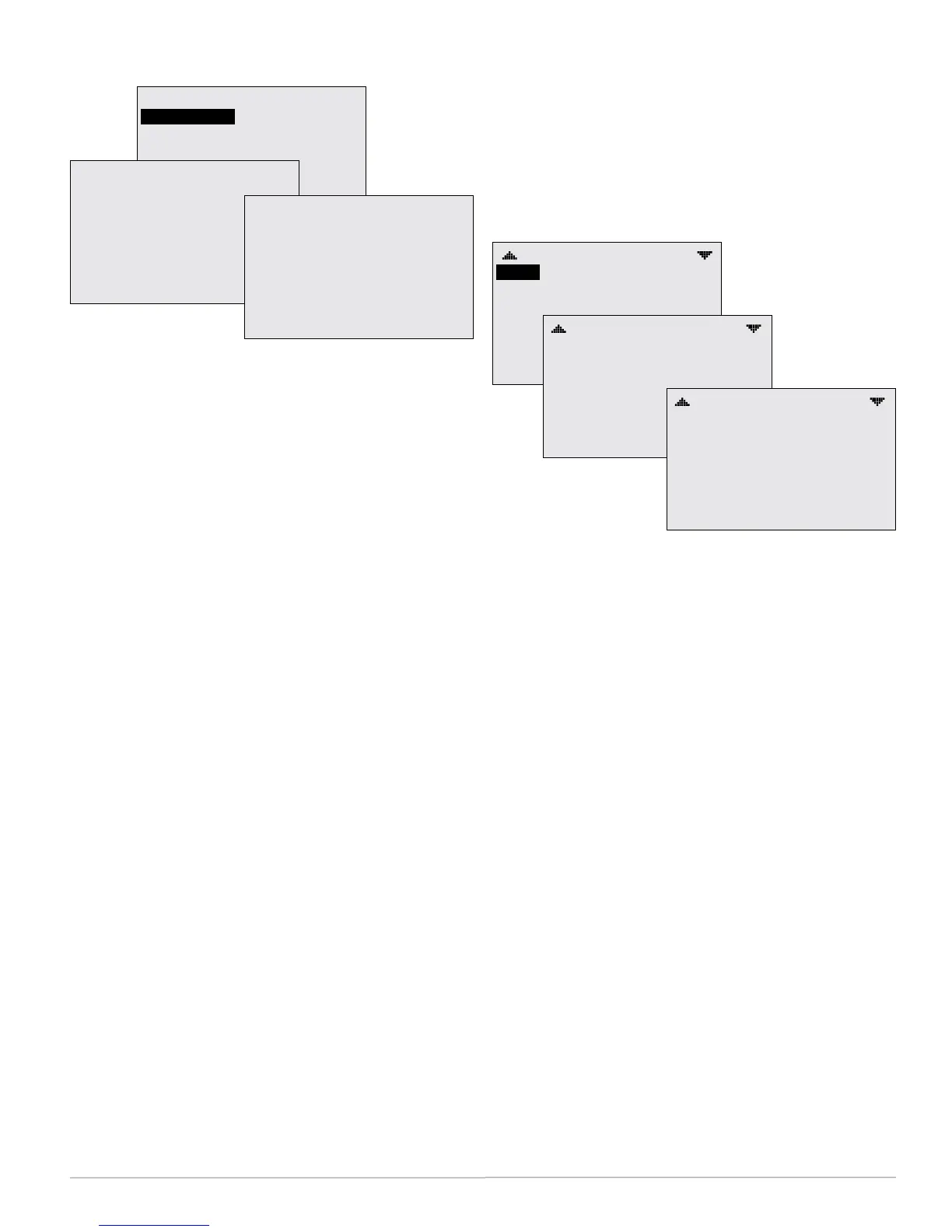

DAMPER SETUP

ECON:

DCV: ADVANCED

DCV SETUP

MIN POSITION: 0%

CNTRL (0–100%): 2–10 V

ECON ENBLE TEMP: 55° F

LOW LIMIT ALARM: 45° F

MODULATING

DCV SETUP

VENT MODE: STARTUP

DCV DAMPER SETUP

CO2 MAX (PPM): 1000

CO2 BASE (PPM): 400

OA AREA: 2%

OA FULL: 5%

OA MAX: 40%

DCV SETUP

OA PURGE: 0%

OA LOW VENT: 65°F

OA HIGH VENT: 80°F

FAN MAX OFF (MINS): 30

CLG DESIGN TEMP: 95°F

HTG DESIGN TEMP: 20°F

VENT OVRIDE (MINS): 30

The CO

2

sensor is used with DCV (Demand Control

Ventilation sequences to provide optimal ventila-

tion and energy savings for a space. When BAC-

12xxxx/13xxxx/14xxxx models have an application

with the CO

2

sensor AND a modulating economizer

option enabled, menu items for DCV (Demand Con-

trol Ventilation) will appear. Most DCV seings are

accessed from the Damper setup menu. See Damper

Setup on page 7, Setpoints on page 25, and DCV (De-

mand Control Ventilation) on page 24.

Although BAC-12xxxx FlexStats do not have a built-

in CO

2

sensor, they still have DCV control sequences

available. When DCV is enabled in the Damper

Setup menu of these models, IN9 is assumed to be

connected to an external SAE-10xx CO

2

(duct or

space) sensor. 0–5VDConthatinput (congured

in the (Advanced) Inputs menu)willmapto0–2000

ppm.TheoutputoftheconnectedSAE-10xxmust

alsobeconguredtomatchtheFlexStat’sinput (see

the installation guide for the appropriate SAE-10xx

model), and the FlexStat’s IN9 pull-upresistor must

be set for 0–12VDC (see the appropriate FlexStat

installation guide)! BAC-13xxxx/14xxxx FlexStats

also have the external sensor option, and if used, the

highest of the two readings (internal vs. external)

will be used to control DCV sequences. The CO

2

ppm

display (if enabled) also shows the highest of the two

levels. (Allow at least 15 minutes after installation for

the reading to stabilize.)

Loading...

Loading...