SECTION 3

OPERATION

July 2003

p 3-6

05132519

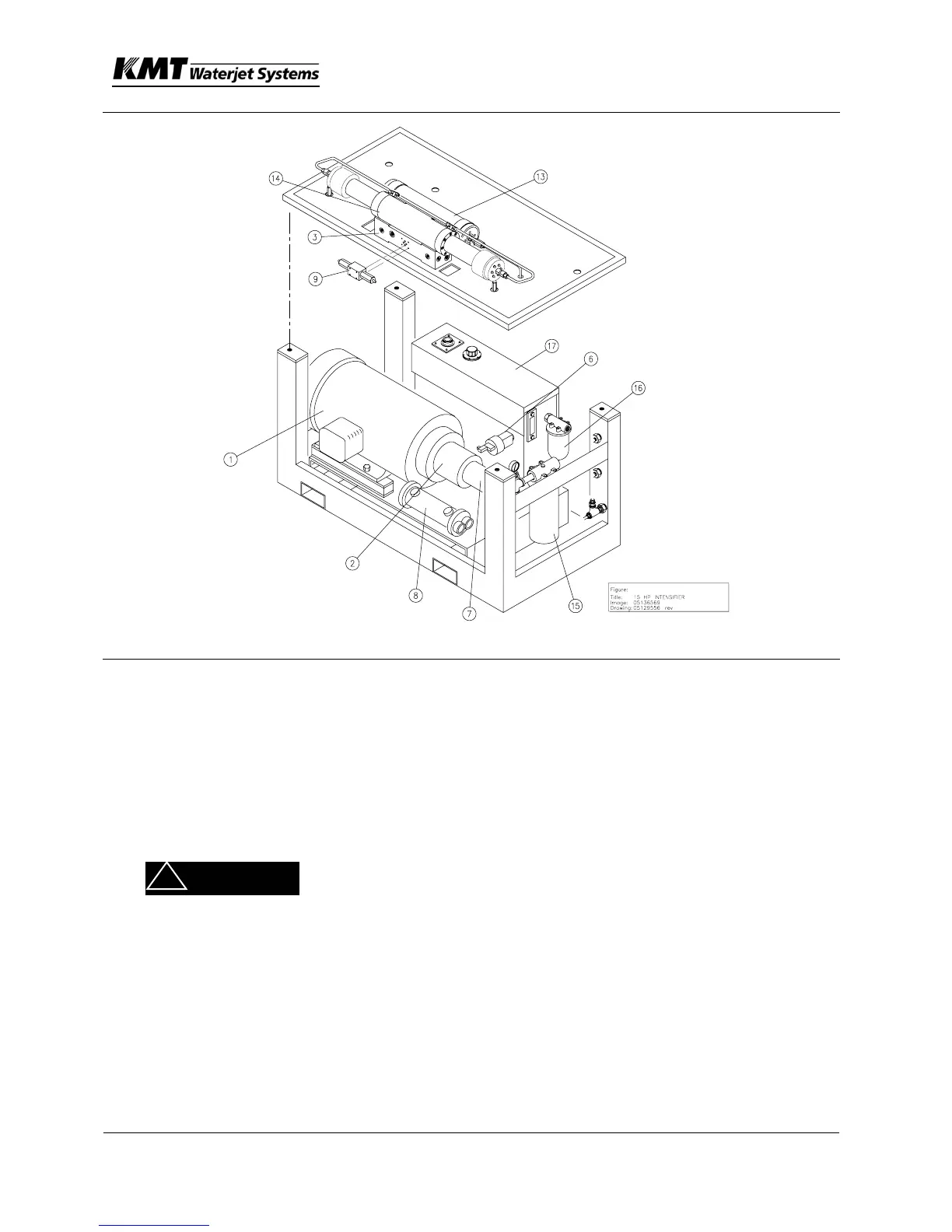

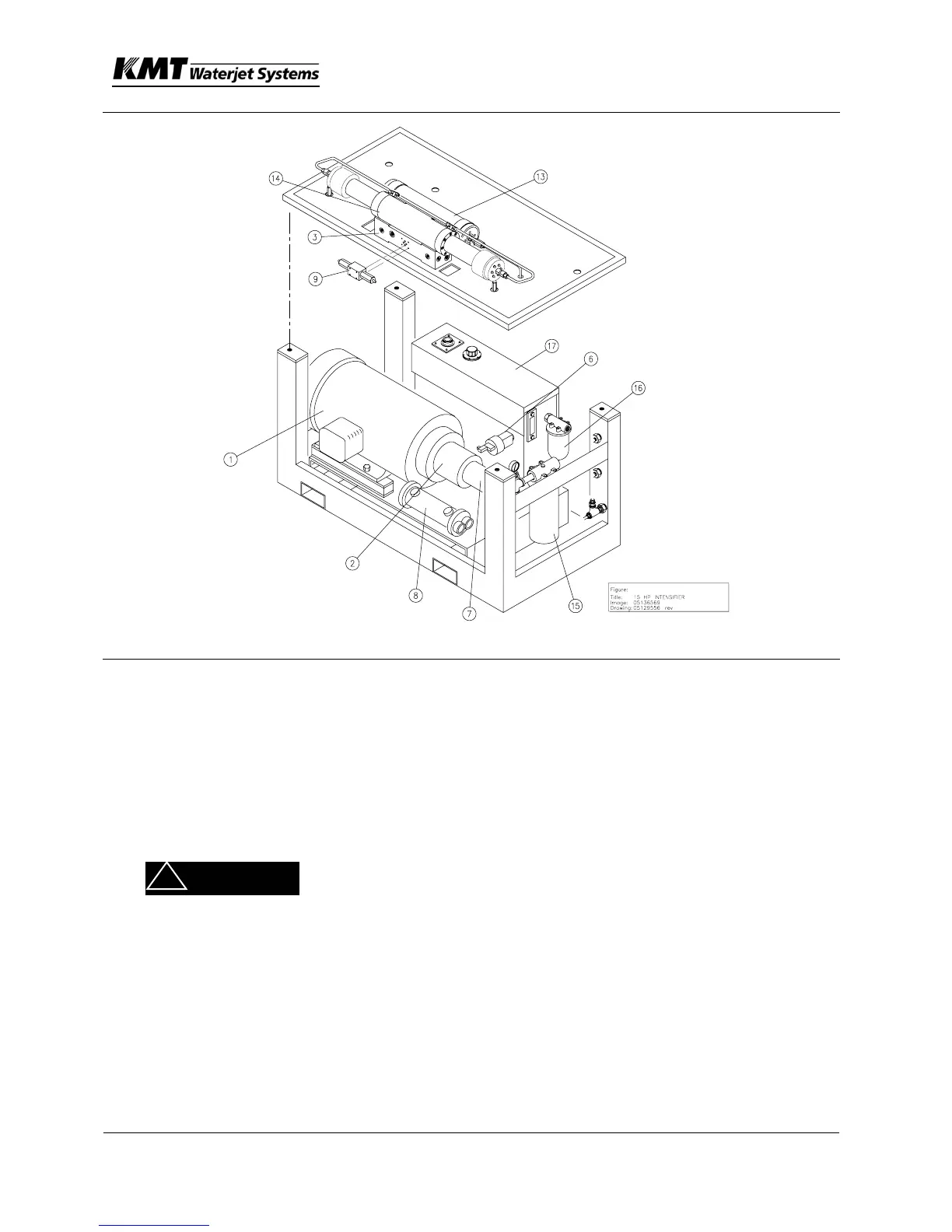

Item Description

1 Electric Motor

2 Hydraulic Pump

3 Manifold

6 Solenoid Shutoff

Valve

7 Hydraulic Gear

Pump

8 Heat Exchanger

9 Directional Control

Valve

13 HP Attenuator

14 Intensifier

15 LP water Filter

16 Oil Filter

17 Hydraulic Reservoir

• Insure all cooling water valves, supply water valves, and high pressure

valves are open.

• Check direction of motor rotation (see arrow).

Do not run the motor backwards, as the hydraulic pump

will likely be damaged.

Motor direction of rotation should be checked any time

electrical maintenance/modification is performed on the

motor starter wiring or on the service wiring to the pump.

Check that inlet cutting water is present before starting SL-

IV Pump.

• At initial startup, run the intensifier at low pressure (refer to procedure in

paragraph 3.3.4) with an open valve in the HP piping system for two

minutes. This procedure will eliminate trapped air in the high-pressure

cylinders, which could become extremely hot when compressed. Trapped air

will cause deterioration of HP seals.

CAUTION

Loading...

Loading...