SECTION 8

ELECTRICAL SYSTEM

July 2003

p. 8-3

05130703

After pressing the START Pushbutton:

• The unloading valve delays hydraulic pressure build-up while the

motor starter circuit accelerates the motor to normal rotating speed.

• The intensifier assembly starts operating. Reversal position is sensed

by proximity switches, which send signals to the relay logic inside the

control panel. The relay logic activates the opposite solenoid on the

directional control valve.

8.2 Maintenance Overview

Electrical components require minimum attention and service.

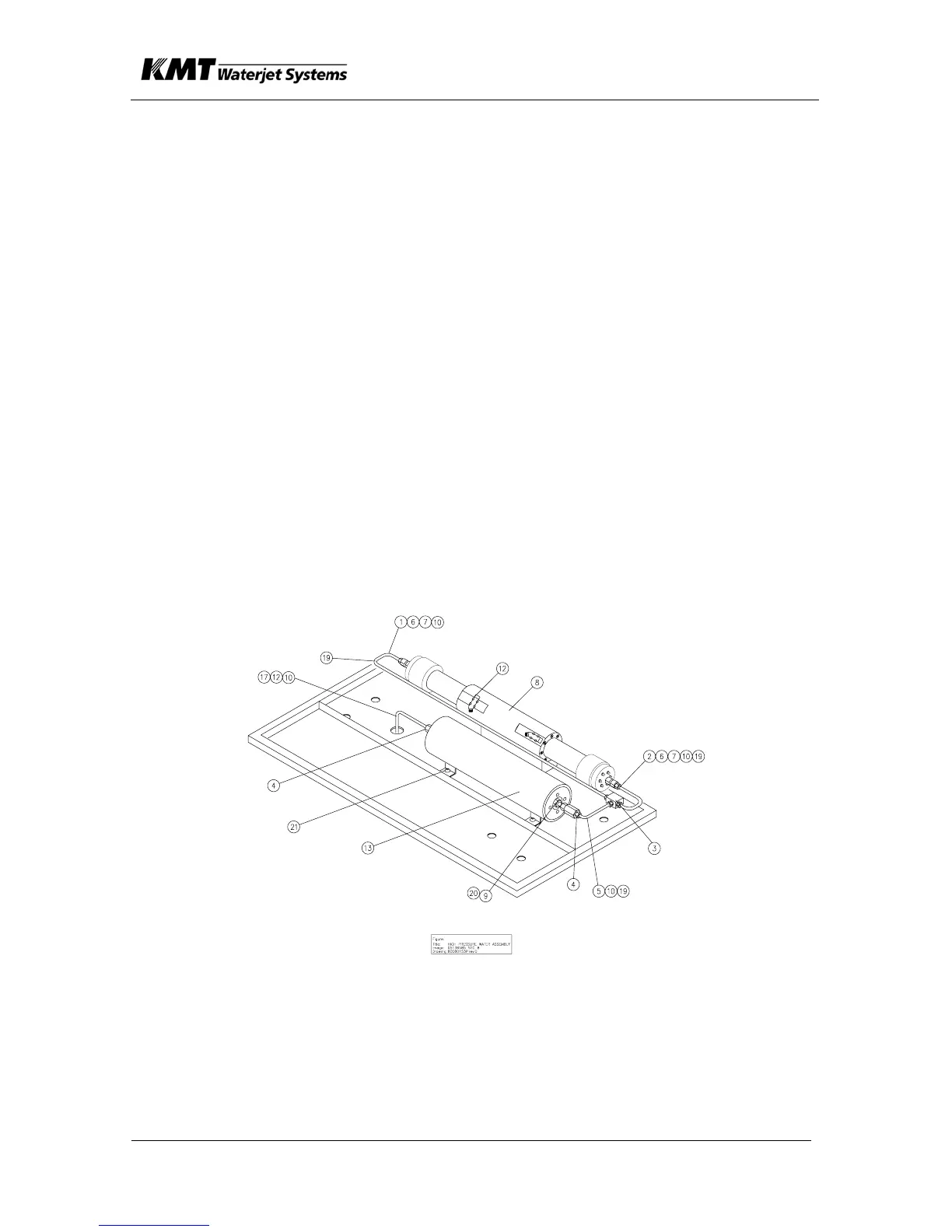

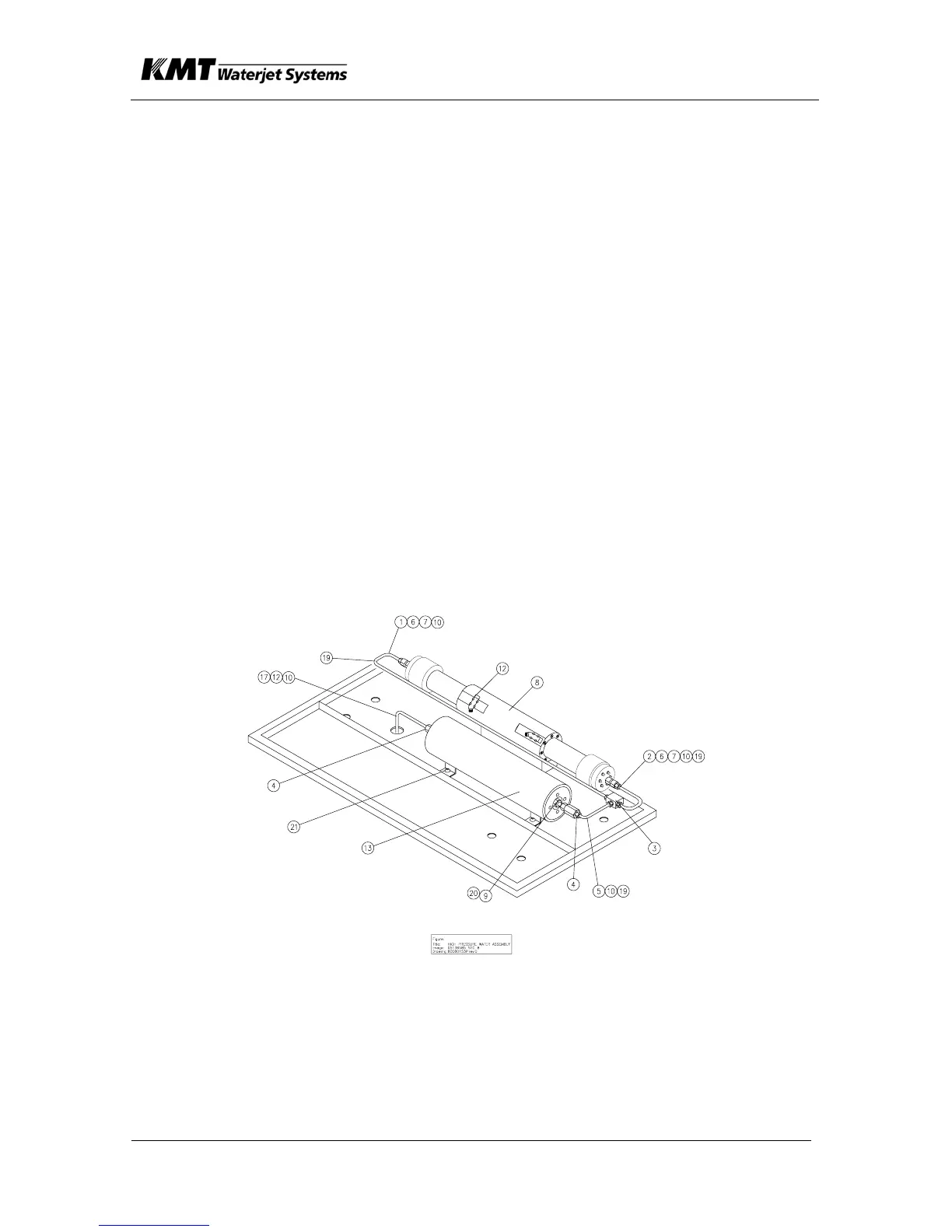

8.2.1 Proximity Switch Service

If the pump quits pumping water, the proximity switch may need to be

replaced. Check the LED lights on the switch.

Symptoms of a failed proximity switch are (1) the LED lights do not

change state (indicating not sensing the piston) or (2) the LED lights are

continuously flashing. Replace the switch when failure occurs.

Recommended Tools:

Allen (hex) Wrench,

M5

Torque Wrench

Rags

Components:

(1) Intensifier

Assembly

(2) Electrical Harness

(3) Proximity Switch

(4) Hydraulic Cylinder

(5) Piston

Parts:

Proximity Switch

1 HP Tube

2 HP Tube

3 Tee Fitting

4 HP Fitting

5 HP Tube

6

Gland Nut - HP

Tube

7 Collar - HP Tube

8 HP Intensifier

9 HP Fitting

10 Ferrule, .25 Hose

12 Proximity Switch

13 HP Attenuator

19 Conduit, Flexible

20 Enclosure End

21 Spacer

Loading...

Loading...