SECTION 4

MAINTENANCE

July 2003

p. 4-3

05130679

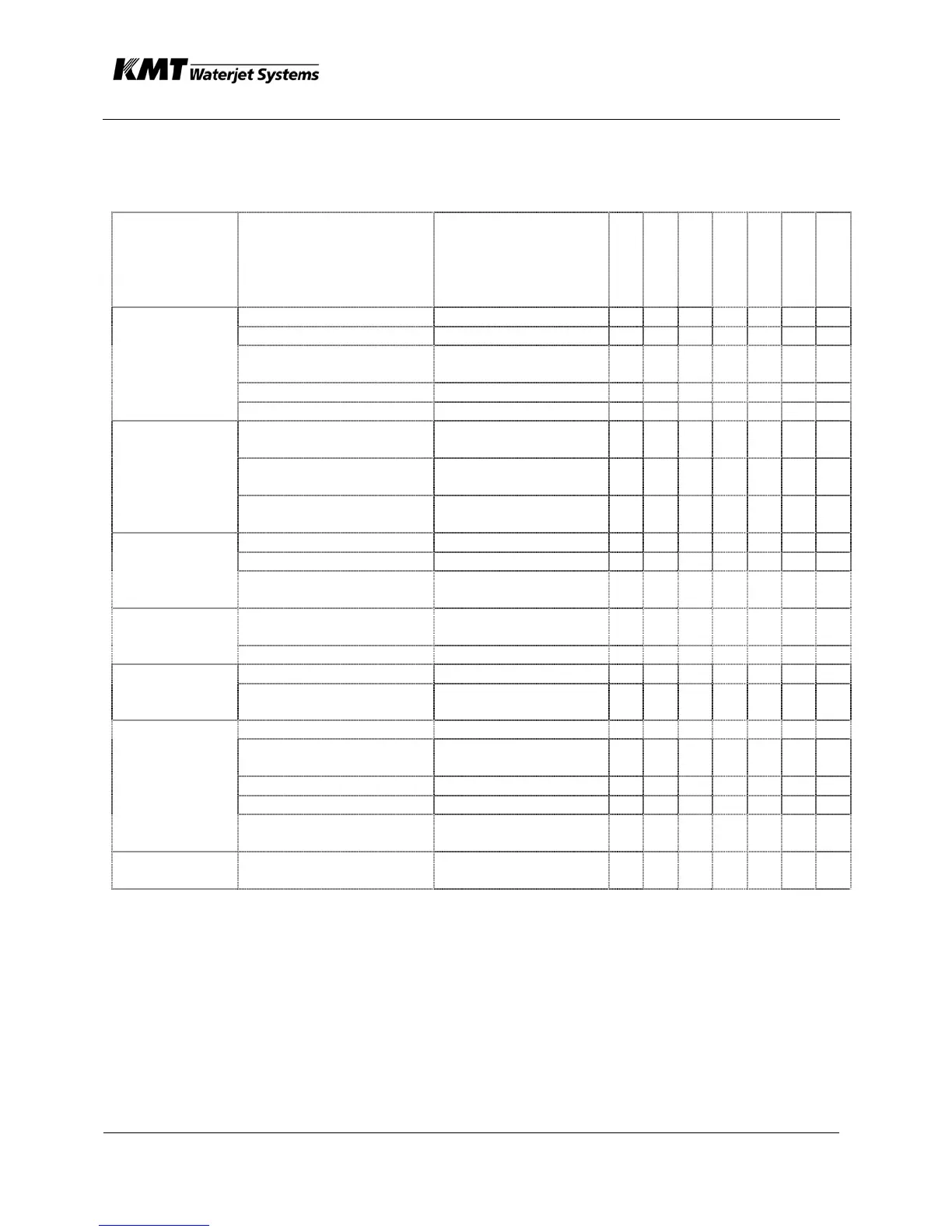

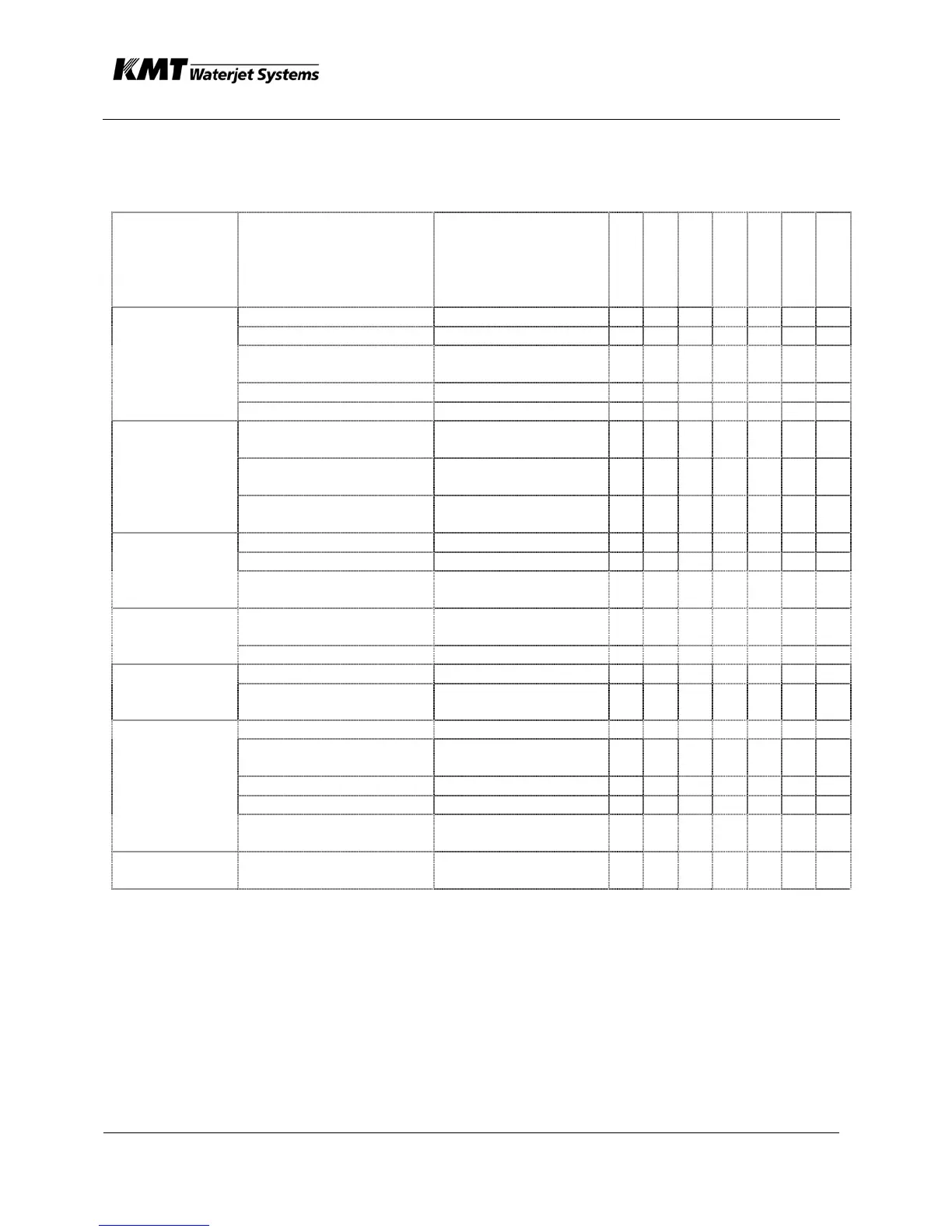

4.1 Scheduled Maintenance

Check

Description

Item to be Checked Major Component

As Req’d

Per Shift

Weekly

Monthly

3-Month

6-Month

Yearly

1

Oil Level Hydraulic Oil Tank X R

Oil Sample Hydraulic System F

Hydraulic Cartridge

Seals

Hydraulic Cylinder X X

Plunger Seals HP Cylinder X X

Fluid Level &

Leak Checks

Sealing Head HP Cylinder X X

Water Supply Pressure

Low Pressure Filter

Assembly

X X

Intensifier

Discharge Pressure

HP Piping X

Pressure &

Flow Checks

Hydraulic Pump

Pressure

Hydraulic Pump X

Plunger Seal HP Cylinder X X

HP Check Valve Port Sealing Head X X

Temperature

Checks

Cooling Water

Inlet/Outlet

Oil/Water Heat

Exchanger

X F

Motor Bearings Lube

Hydraulic Power

Unit

X R

Lubrication

& Filter

Checks

Hydraulic Filter Hydraulic Oil Tank X X R

Electric Motor F Vibrations-

Rotating

Equip.

Hydraulic Pump F

Hydraulic Pump F

HP Tubing, Valves, &

Fittings

F

Hydraulic Manifold Hydraulic Intensifier F

Control Panel Electrical Enclosure F

System

Cleaning &

Inspections

Gage Calibration

Hydraulic Pump &

HP Piping

F

Control

Lights

X

Key:

F: Information

X: To be observed

R: To be replaced

1

Yearly or 3,000 hours, whichever comes first.

4.2 General Maintenance

Proper maintenance is important for reliable and consistent performance. Preventive

maintenance reduces unscheduled downtime, and extends component life.

Loading...

Loading...