Submersible motor pumps (100 mm)

Annexure I - Environment Protection - Product Disposal after useful life

Products manufactured by KSB are designed with an extreme care for environmental protection. Innovative designs and wide

product ranges take care of customer’s requirements reducing material and electrical energy consumption. Product materials are

recyclable. Our customers are educated with environment friendly methods of disposing product ingredients at the end of product

useful life. Please find herewith methods of disposing used ingredients.

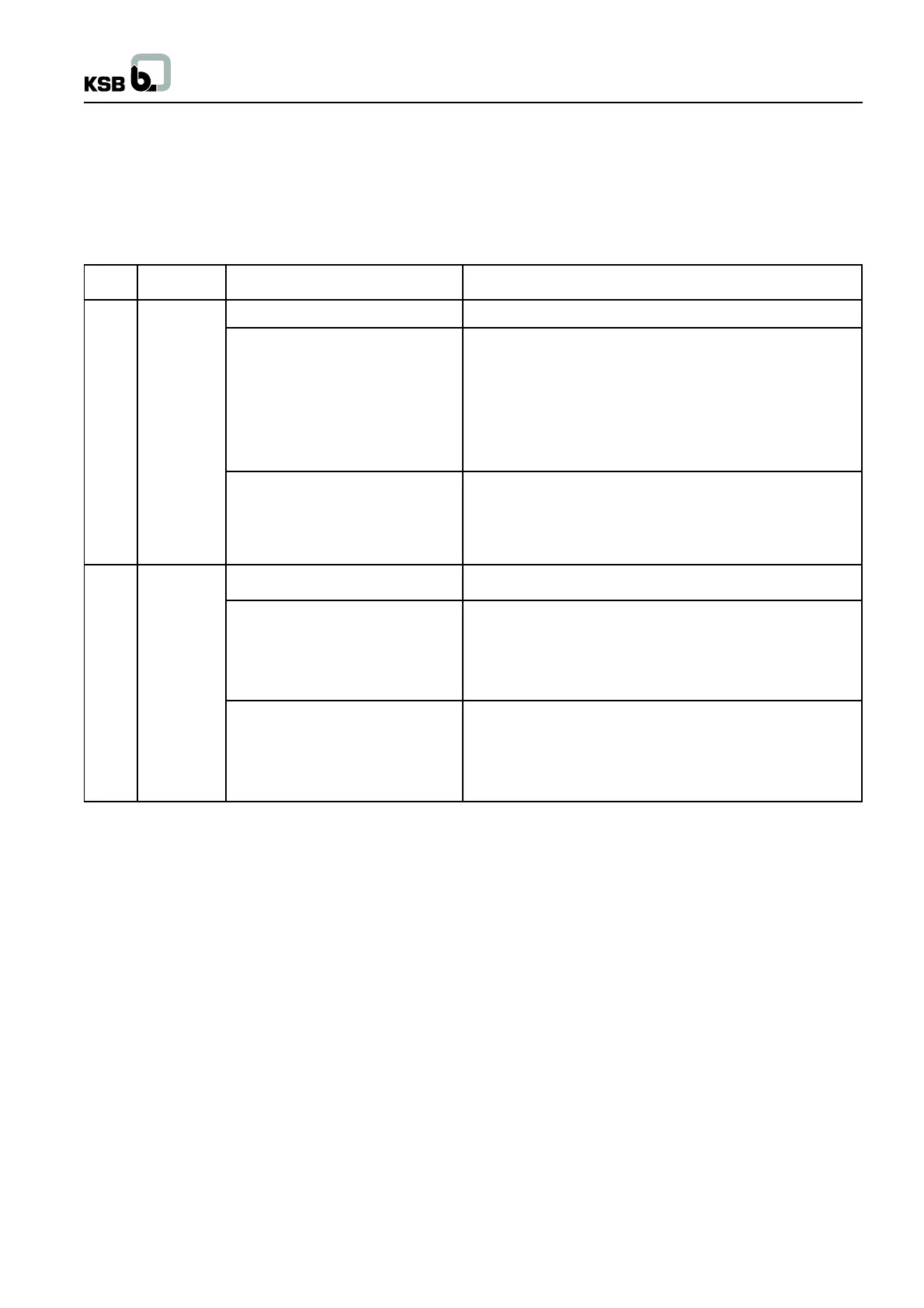

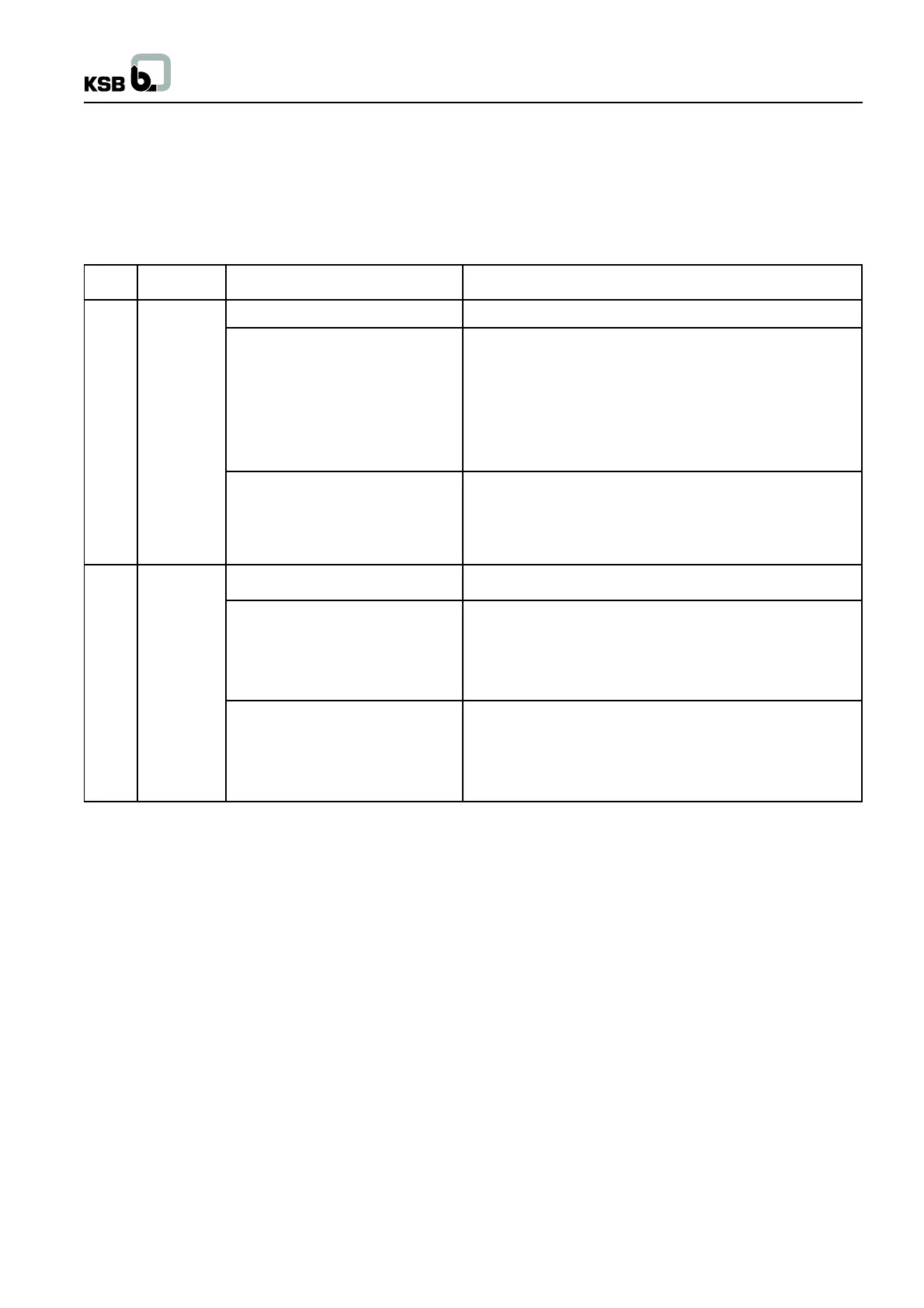

Environment Protection measures during product disposal

Sr. Product Ingredients Disposal Methods

1. Pumps Paint : Pump body, Base frame Sludge to be disposed through authorized re-processor

Non ferrous parts :

a) Impellers, Diffusers

b) Bushes

c) Stage sleeves

d) Thrust plate Sludge to be disposed through authorized re-processor

e) Wearing ring

f) Coupling Guard

g) Brg. Guard

Rubber / Plastic Parts :

a) Cover for NRV

b) Plastic cap Sludge to be disposed through authorized re-processor

c) Nozzle blanking

d) Cooling Fan

2. Motor Paint : Motor body, Rotor Sludge to be disposed through authorized re-processor

Non ferrous parts :

a) Support bushes

b) Copper sticks and stampings Sludge to be disposed through authorized re-processor

c) Balancing rings

d) Winding wire with varnish

Rubber / Plastic Parts :

a) Oil seal

b) Sand guard Sludge to be disposed through authorized re-processor

c) Notch keys, slot insulators

d) Overhang protection pipe

17

Loading...

Loading...