Submersible motor pumps (100 mm)

3

2.3 Typical installation at site

Use lifting device of capability of carrying the weight of pump

unit as well as the weight of pipe filled with water for installation.

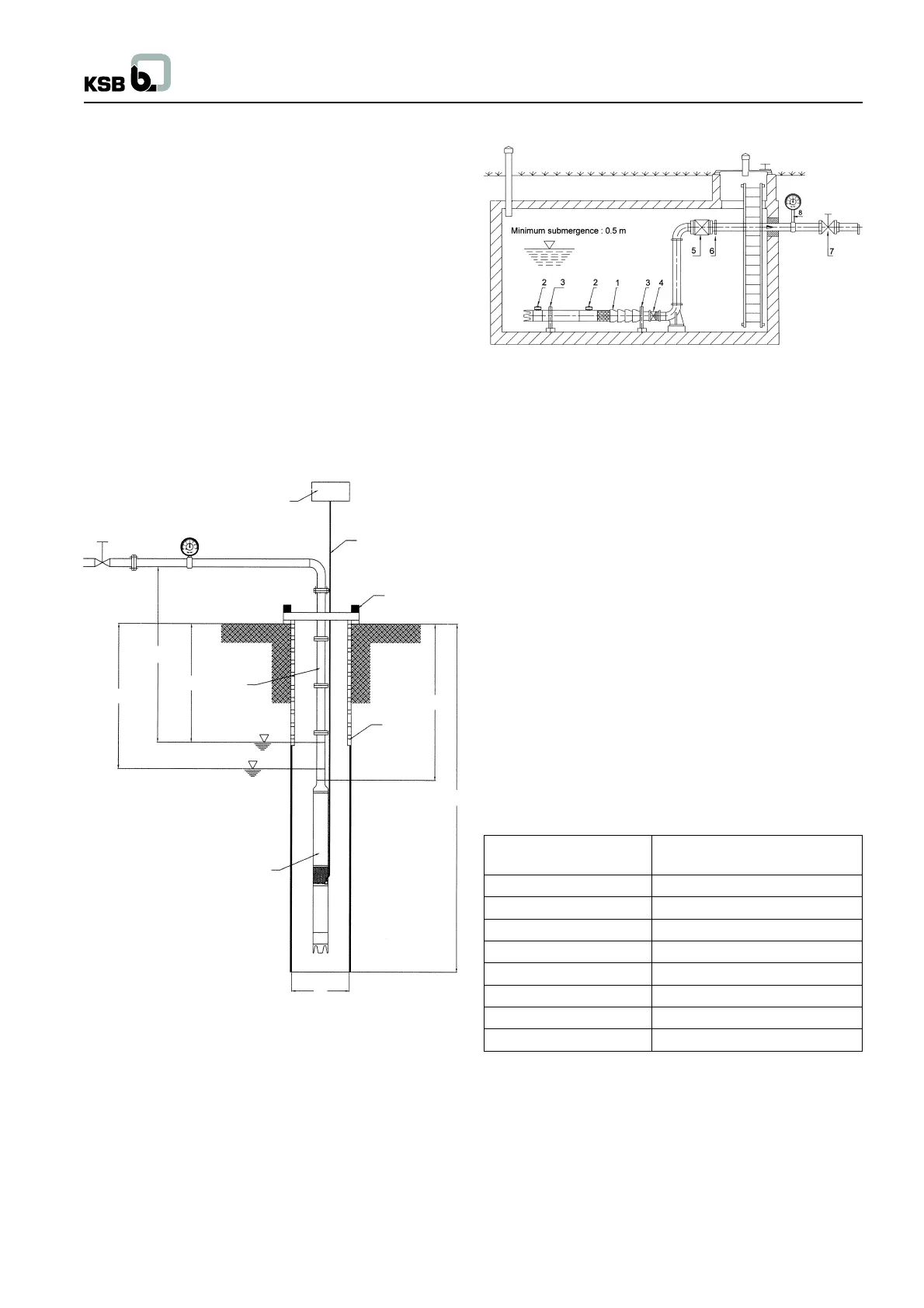

2.3.1 Vertical installation

Before installing the unit in narrow deep wells, the well should be

tested for trueness of size over its entire length (e.g. by running

a dummy cylinder of diameter 98 mm and length about 2 m inside

the well). A slight inclination of the well is immaterial, whereas

any twists or bends can make installation difficult.

Installation depth should be selected such that the motor would

never run dry even when the water level is at its lowest mark

(i.e. draw down of bore well capacity).

The minimum water level should be 0.5 m above the top of the

non-return valve.

The pump should always be installed with the suction strainer

above the slotted casing pipe. The effect is that the pump draws

in the water free from loose sand.

1. Discharge valve

2. Supporting clamp

3. Raiser pipe

4. Submersible motor-Pump set

5. Power supply cable

6. Starter

7. Slotted Casing pipe

(Length up to rock level)

8. Pressure Gauge

D = Well diameter

T

B

= Well depth

H

e

= Installation depth

H

h

= Stationary water level

H

t

= Operation water level

H

geo

= Geostatic head

Ht - Hh = Drawdown

Notes for installation :

The motor pump unit must be immersed minimum 0.5 m more

below the lowest operation water level H

t

.

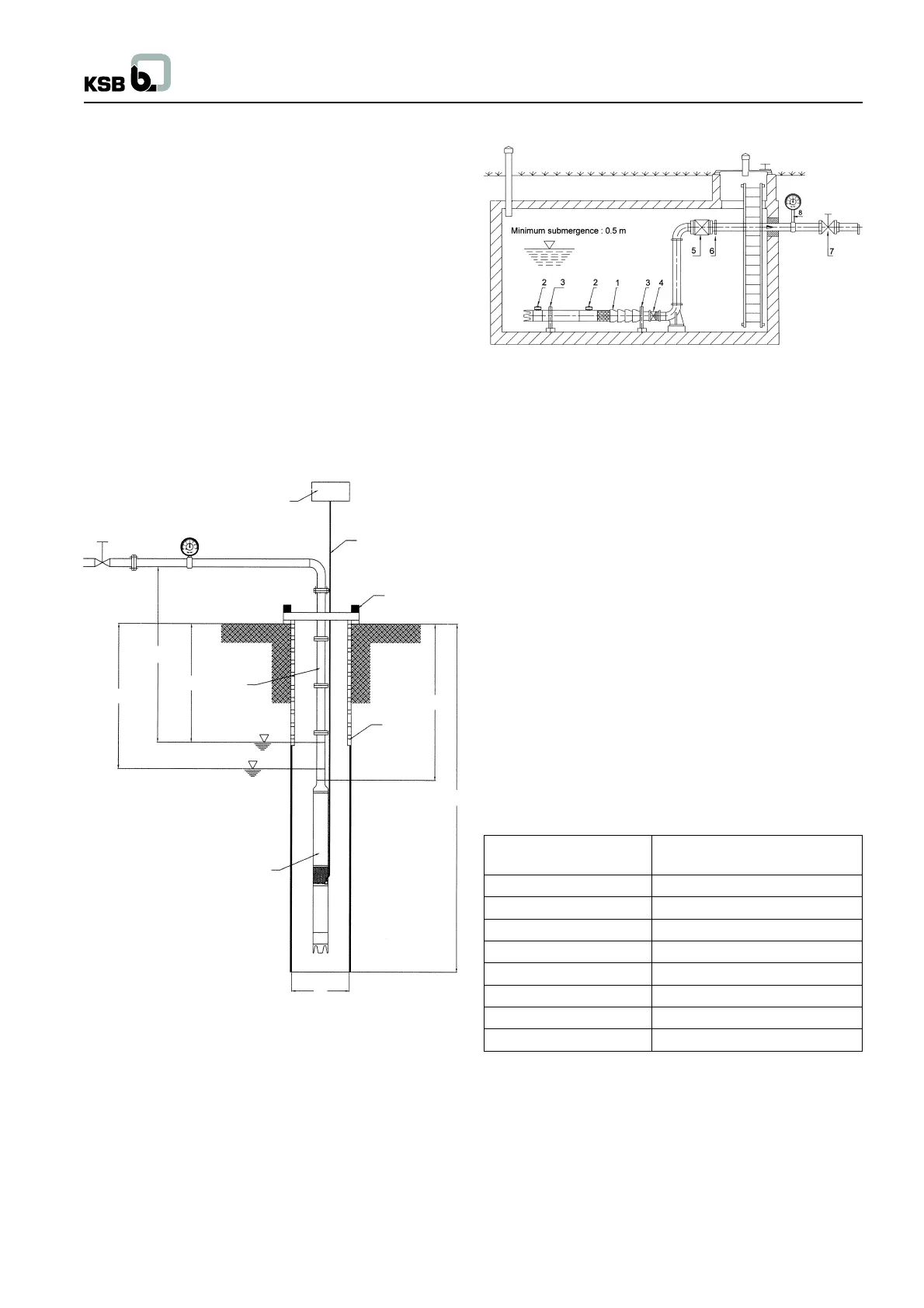

2.3.2 Horizontal Installation (e.g. in tank or pit)

Note : Generally the horizontal installation of submersible pump

unit is equipped with two storage tanks to increase the water

capacity.

1. Referring to the above figure (Fig. 4) for horizontal installation

only two supports are needed. One is placed at the extreme

end of the NRV while other is placed at the center of motor.

2. Install adapter pipe to the pump with 2 Water reservior and

the motor with proper fittings.

3. Ensure that the cast RCC foundation is incorporated with

the recommended foundation bolts of proper height.

4. To make up the correct center height of aligned pump - motor,

provide sufficient metallic packing in the RCC foundation

itself. To attain precise alignment, minor shims up to 2 mm

thick made of M.S. sheet may be used below the pump or

motor stand.

5. Such installed pump shall be either perfectly horizontal or

maximum of 5 degree inclination with motor down and pump

lifted up from the ground. Precise tightening of foundation

bolts has to be done at the final stage.

6. Surface of the motor should be cleaned periodically for

effective cooling.

1. Submersible pump unit

2. Water reservior for Motor

3. Support

4. Expansion joint

5. Non-return valve

6. Flange adapter

7. Discharge valve

8. Pressure gauge

It is important to ensure that pump does not sit on the base of the

well and there is no risk of sand or sludge deposition around the

motor. This would disrupt heat dissipation from the motor.

2.3.3 Plastic / Flexible Rubber riser piping instead

of normal GI riser piping

Consult the HDPE / rubber pipe suppliers for the capability of

pipes for withstanding the pressure. If the pump is to be fitted

with HDPE raising piping, it is to be firmly tied up with stainless

steel wire ropes of dia. 2-3 mm to the eyelets on the non return

Fig. no. 3

1

8

6

5

2

3

7

H t

H geo

H h

H e

T

8

4

D

Pump type Max. no. of stages allowed

for horizontal installation

CORA 1C & CORA 2C 30

CORA 4C 23

CORA 7C 19

CORA 12C 8

CORA 18C 8

CORA 2AH 17

CORA 3AH 12

CORA 3A 15

Fig. no. 4

Loading...

Loading...