Multitec

- The tolerances stipulated for mounting the unit on the

foundation, for shims and alignment have been met.

- The pipeline have been connected without warping the pump

nozzles.

- Electrical connection and relay setting correspond to the motor

rating and comply with the applicable regulations.

- The unit has been equipped with all hydraulic, electrical and

mechanical protection devices.

- The pump has been fully primed with the medium to be

handled.

- The unit’s direction of rotation corresponds to the rotation

arrows.

- All connections are tight.

For installation without foundation (e.g. on spring

elements) care has to be taken that all movements

of the pump unit can be compensated, e.g. by installation of

expansion joints in the discharge and suction lines.

6.1.1 Lubricating agent

Grease lubricated bearings

The grease lubricated bearings are packed with grease at the

factory.

Oil lubricated bearings

Into the bearing cover fill oil of the quality HD 20 (ISO VG 46)

(see point 7.2.2).

6.1.2 Priming the Pump and Checks to Be Carried

out

Before each start-up, the pump and suction line must be

completely vented and primed with the liquid to be pumped. The

pump has several plugged holes for venting; adequate venting

devices can be used in the pipelines. The shutoff element in the

suction or feed line must be fully open.

Fully open all auxiliary connections provided and check the

throughflow.

Open shut-off valve “C” in the vacuum balance line (if applicable),

close vacuum-tight shut-off valve “E” (see 5.4.1).

Dry running will lead to increased wear on the unit

and possibly to damage on the pump !

If the discharge line is equipped with an automatic check valve,

open the minimum flow valve and secure against inadvertent

closing.

Exceptions :

- If the check valve is not subjected to backpressure prior to

pump start-up, the check valve must be closed first.

- On pumps fitted with a mechanical seal, the mechanical seal

will leak only slightly or invisibly (vapour) during operation. It

is maintenance-free.

- If the pump is equipped with a gland packing, leakage during

operation is normal (see section 6.1.6).

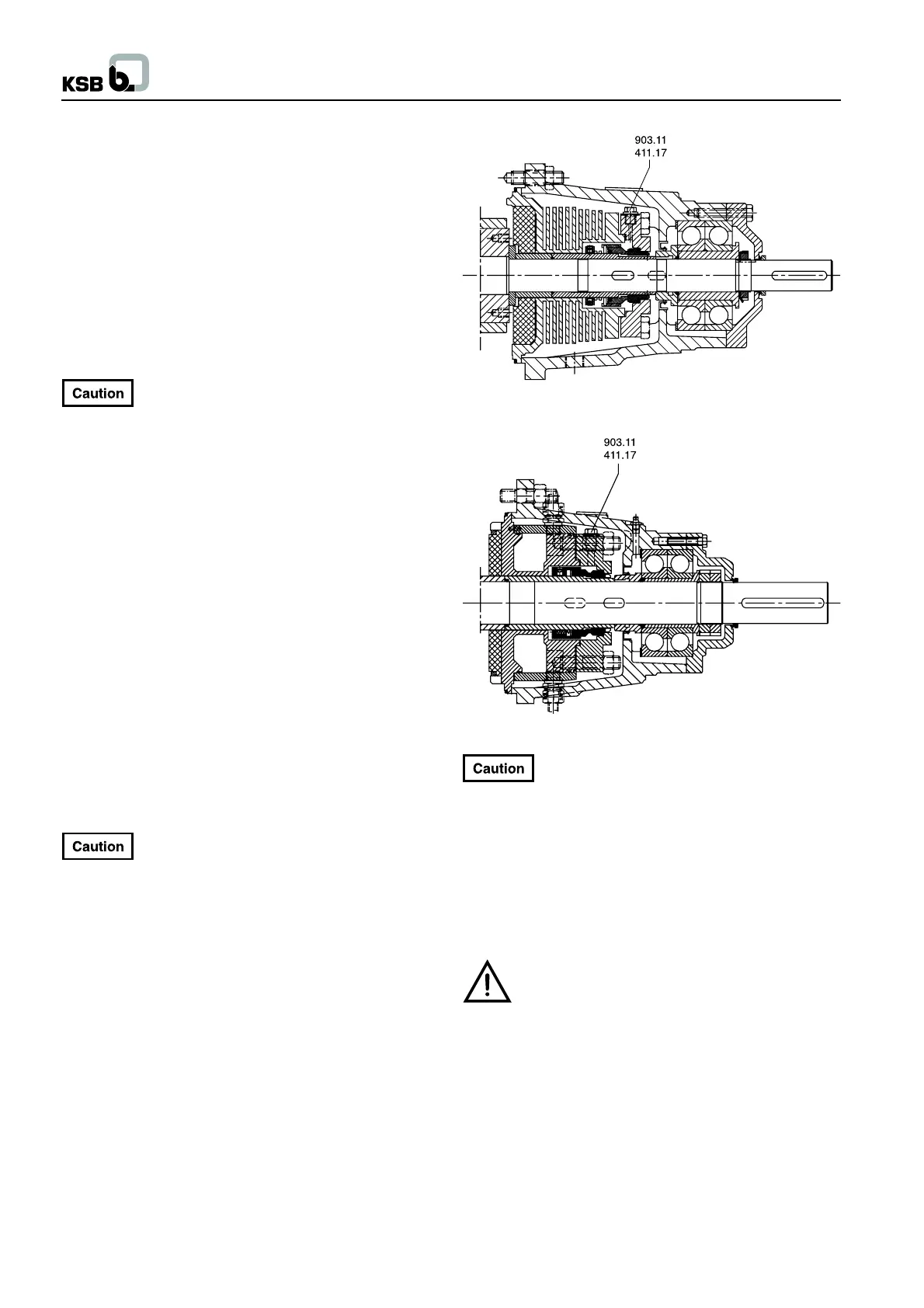

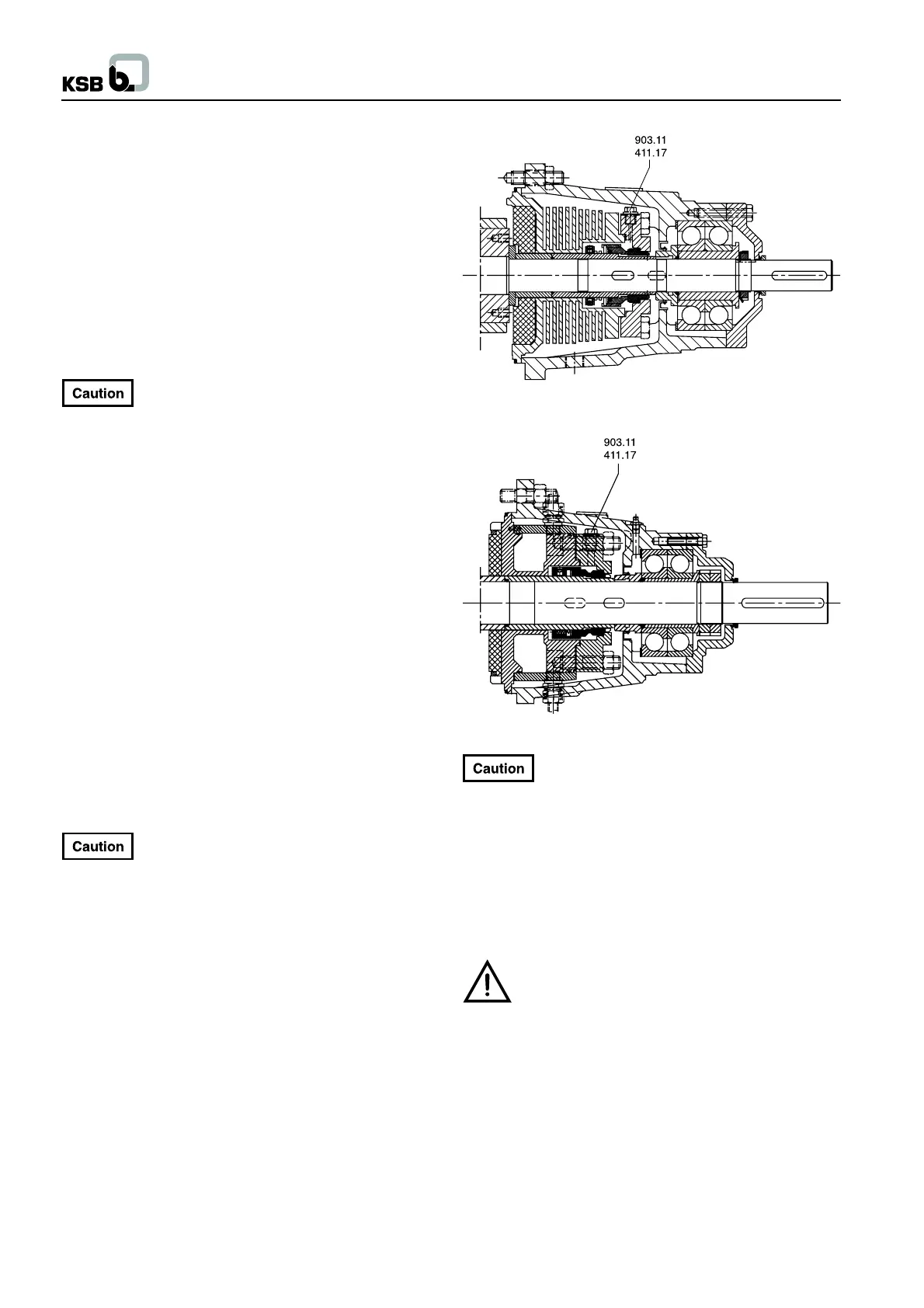

Special notes regarding cooled mechanical seals

(Sealing Code 64)

- If the pump is equipped with a cooled mechanical seal, vent

the seal chamber by opening the screwed plug 903.11 by a

quarter turn, then retighten.

Sizes 32 to 100

Sizes 125 and 150

Fig. 6.1-1

Fig. 6.1-2

The seal chamber has to be vented when the pump

is in cold condition before start-up. When venting

in hot condition, the steam will exit at the screwed plug during

the venting process and there is the risk of scalding ! Should it

not be possible to avoid the open of the seal chamber in hot

condition due to the situation in the plant, a pipe with valve (not

included in KSB’s scope of supply) has to be installed at the

venting hole, in order to lead the exiting steam during venting to

another place where there is no danger of scalding. It should be

made certain that this valve cannot be opened during operation.

6.1.3 Contact Guard

In compliance with accident prevention regulations the

pump must not be operated without a coupling guard.

If the customer specifically requests not to include a

coupling guard in our delivery, then the operator must supply

one.

6.1.4 Connection to Power supply

If the pump is equipped with an electric motor, connection to the

power supply must be effected by a trained electrician only.

Check available mains voltage against the data on the motor

rating plate and select appropriate start-up method.

Make sure that in the case of three-phase motors with star-delta

starting method switching over from star to delta will be effected

at very short intervals. Prolonged switch-over intervals may result

in pump damage.

8

Loading...

Loading...