Multitec

7.3.5.3 Removing a Double-Acting Mechanical

Seal

Mechanical seals in tandem, face-to-face and back-to-back

arrangement are fitted as per customer specifications. There is

a wide variety of variants, types and brands. Please refer to the

general drawing and the documentation supplied with the pump

for orientation.

7.3.6 Dismantling the Hydraulic Elements

- Remove the bearings as described in sections 7.3.3.1 and

7.3.3.2 and the shaft seals as described in sections 7.3.4 and

7.3.5.

It possible, place the hydraulic system in vertical position and

start dismantling it from the discharge end.

- Loosen the four tie bolts 905.

- Remove discharge casing 107 and then the hydraulic system.

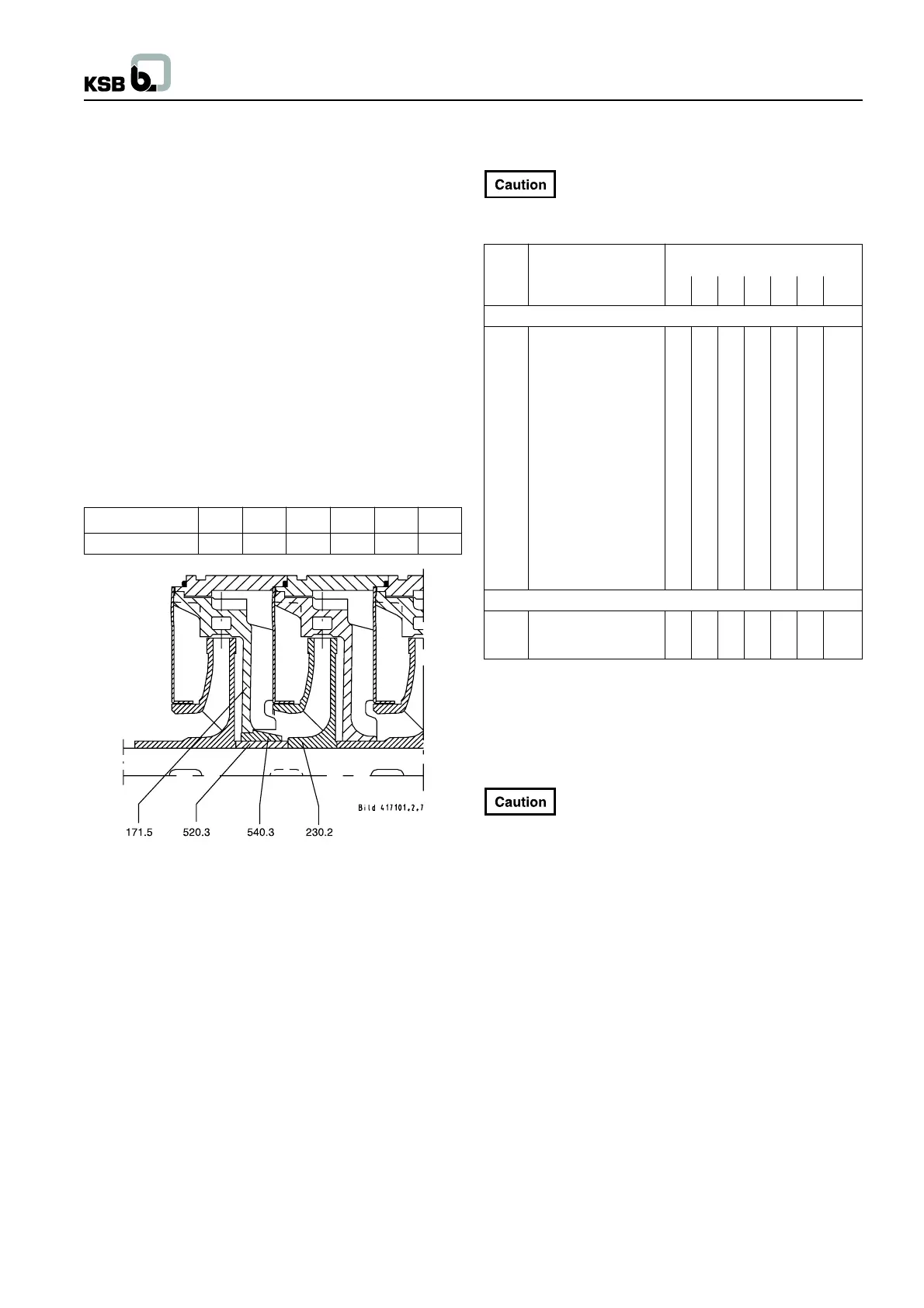

N.B.: The pump version A/B/C/D in material variants 22/23/30

have an intermediate bearing in the middle stage as of the number

of stages listed in the table (see Fig. 7.3-12).

Pump size 32 50 65 100 125 150

No. of Stages 8 7 6 6 5 6

Fig. 7.3-12

540.3 Intermediate bearing-bush

520.3 Intermediate bearing-sleeve

171.5 Intermediate bearing-diffuser

230.2 Intermediate bearing-impeller

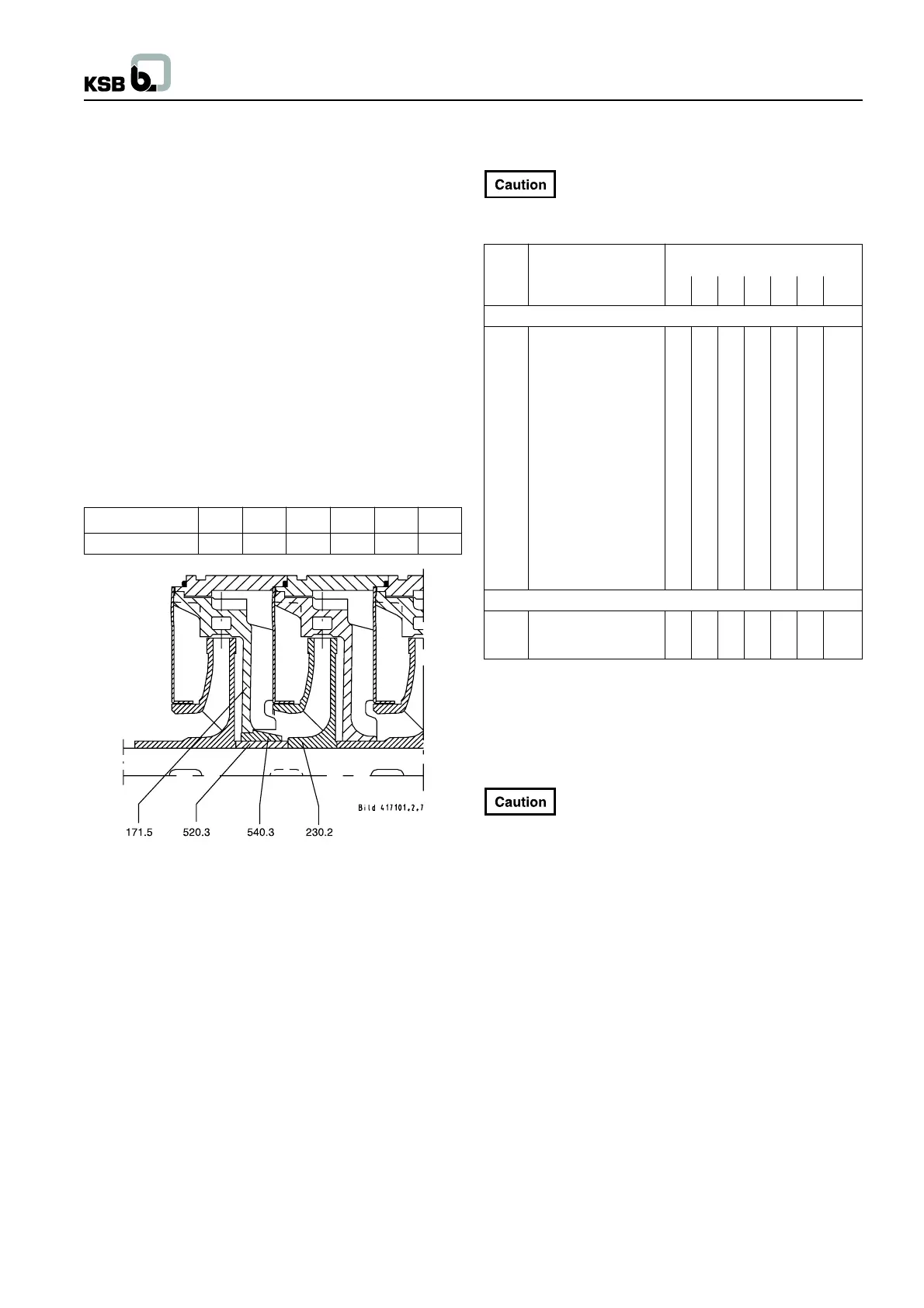

7.3.7 Recommended Spare Parts Stock for 2

Years’ Continuous Operation

We recommend to replace different wear parts

(such as rolling element bearings, sealing elements,

circlips etc.) whenever the entire hydraulic system is dismantled

(See spare parts list below).

Part No. Description Number of pumpr

(including stand-by pumps)

2 3 4 5 6+7 8+9 10 and

more

For shaft seal codes 65 and 66 (gland packing)

210 Shaft with small parts 1 1 2 2 2 3 30 %

230 Impeller (set = S) 1 1 1 2 2 3 30 %

231 Suction impeller 1 1 1 2 2 3 30 %

320.1 Fixed bearing (set) 1 1 2 2 3 4 50 %

320.2 Radial bearing 1 1 2 2 3 4 50 %

381 Bearing cartridge 1 1 2 2 3 4 50 %

411 V-ring (set) 4 8 8 8 9 12 150 %

412 O-ring (set = S) 4 8 8 8 9 12 150 %

461 Gland packing (set) 4 6 8 8 9 12 150 %

502

1)

Casing wear ring (set) 2 2 2 3 3 4 50 %

520 Sleeve 1 1 2 2 3 4 50 %

524 Shaft protecting sleeve 2 2 2 3 3 4 50 %

525 Spacer sleeve 2 2 2 3 3 4 50 %

529 Bearing sleeve 1 1 2 2 3 4 50 %

540 Bush 1 1 1 2 2 3 30 %

550.1

2)

Disc 2 2 2 3 3 4 50 %

59-4 Balance drum 1 1 1 2 2 3 30 %

For shaft seal codes 61, 62, 63 and 64 (with mechanical seal)

433 Complete mechanical seal 2 3 4 5 6 7 90 %

3)

523 Shaft sleeve (set) 2 2 2 3 3 4 50 %

1) only pump sizes 125 and 150

2) only pump sizes 32 to 100

3) Parts 461 and 524 unassembled

N.B.: Please always indicate the works number stamped onto

the pump name plate when ordering spare parts.

7.4 Reassembly

The pump shall be reassembled in accordance with

the rules of sound engineering practice :

- Under no Circumstances use force.

- Due to their weight, some pump components must be

supported during reassembly.

- Before reassembly, the locating surfaces of the individual

components must be coated with a mounting aid in compliance

with hygienic health and safety regulations.

- The properties of new pump components must not be altered

without prior consultation with our technical departments.

- The parts must be clean and free from shavings or dust.

- Reassembly is effected in reverse order to dismantling.

- The tightening torques indicated must be complied with. Avoid

the use of mounting aids as far as possible. Should amounting

aid be required after all, use a commercially available contact

adhesive, e.g. Pattex, HYLOMAR or Epple 33, after prior

consultation with our technical departments. The adhesive

must only be applied at selected points and in thin layers. Do

not use cyano-acrylate adhesives (quick-setting adhesives).

17

Loading...

Loading...