Multitec

7. Maintenance / Repair

7.1 General Instructions

The operator is responsible for ensuring that all maintenance,

inspection and installation work is carried out by authorised, duly

qualified staff who are thoroughly familiar with these operating

instructions.

A regular maintenance schedule will help avoid expensive repairs

and contribute to trouble-free, reliable operation of the pump with

a minimum of maintenance expenditure and work.

Work on the unit must only be carried out with the electrical

connections disconnected. Make sure that the pump set

cannot be switched on accidentally.

Pumps handling liquids posing health hazards must be

decontaminated. When draining the medium see to it

that there is no risk to persons or the environment. All

relevant laws must be adhered to.

7.2 Maintenance / Inspection

7.2.1 Supervision of Operation

The pump must run quietly and free from vibrations at all times.

The pump must never be allowed to run dry. Max. ambient

temperature : 40

0

C.

The bearing temperature may exceed ambient temperature by

up to 50

0

C but must never rise above +90

0

C (measured on the

outside of the bearing bracket), see section 7.4.4.1.

Prolonged operation against a closed shut-off element

is not permitted, to prevent the medium handled from

heating up.

Caution : Required minimum flows see 6.2.3.

The shut-off element in the inlet line must not be closed

during pump operation.

The mechanical seal leaks only slightly or invisibly (vapour)

during operation. It is maintenance-free.

Gland packings must leak slightly (individual drops).

Any stand-by pumps installed shall be switched on and then

immediately off again once a week to keep them operational.

Attention shall be paid to the correct functioning of the auxiliary

connections.

7.2.2 Bearings and Lubrication

For the variant with grease lubrication, the rolling element

bearings of the Multitec 32 as well as the rolling element bearing

of the non-drive end of the Multitec 50 and 65 in design C and D

are lubricated for life and do not require any relubrication. In this

case, there are no lubricating nipples on the bearing brackets.

Pump

Depending on the pump version, the rolling element bearings

are grease-lubricated or oil-lubricated.

Grease Quality / Grease Change

The bearings are packed with high-quality lithium-soap grease.

Depending on the size of the pump and the operating hours of

the pump, the rolling element bearings must be re-lubricated or

the grease in the rolling must be replaced.

Speed (1/min)

Size MTC < 1800 2950 3550

32-50-65 10000h 7200h 5700h

100-125 9000h 5700h 3900h

150 8300h 4000h 3100h

If re-lubrication intervals are short, it is recommended to

completely exchange the grease once a year. If this is not the

case, a complete exchange must take place at least every two

years. When doing so, the rolling element bearings must be

dismantled, cleaned and packed with new grease.

In case of unfavourable operating conditions, e.g. high ambient

temperatures and high air humidity, dust-filled air, aggressive

industrial atmospheres etc., the bearings should be controlled

earlier and, if necessary, cleaned and packed with new grease.

Under normal conditions grease-lubricated rolling element

bearings will run for 15,000 operating hours of 2 years. Thereafter,

the bearings have to be dismantled, cleaned and re-packed with

grease. Under unfavourable operating conditions, e.g. high room

temperature, high atmospheric humidity, dust-laden air,

aggressive industrial atmosphere etc., the bearings should be

checked earlier and cleaned and re-lubricated, if required.

Use a high-quality lithium-soap grease, free of resin and acid,

not liable to crumble and with good rust-preventive characteristics.

The grease shall have a penetration number between 2 and 3,

corresponding to a worked penetration between 220 and 295

mm/10. Its drop point must not be below 175

0

C. The bearing

cavities must only be half-filled with grease.

If required, the bearings may be lubricated with greases of other

soap bases. Since greases of differing soap bases must not be

mixed, the bearings must be thoroughly cleaned beforehand. The

re-lubrication intervals required must then be adjusted to the

greases used.

Oil Quality / Oil Change

Quality : HD 20

The first oil change shall be made after 300 operating hours, all

subsequant oil changes after every 3000 operating hours.

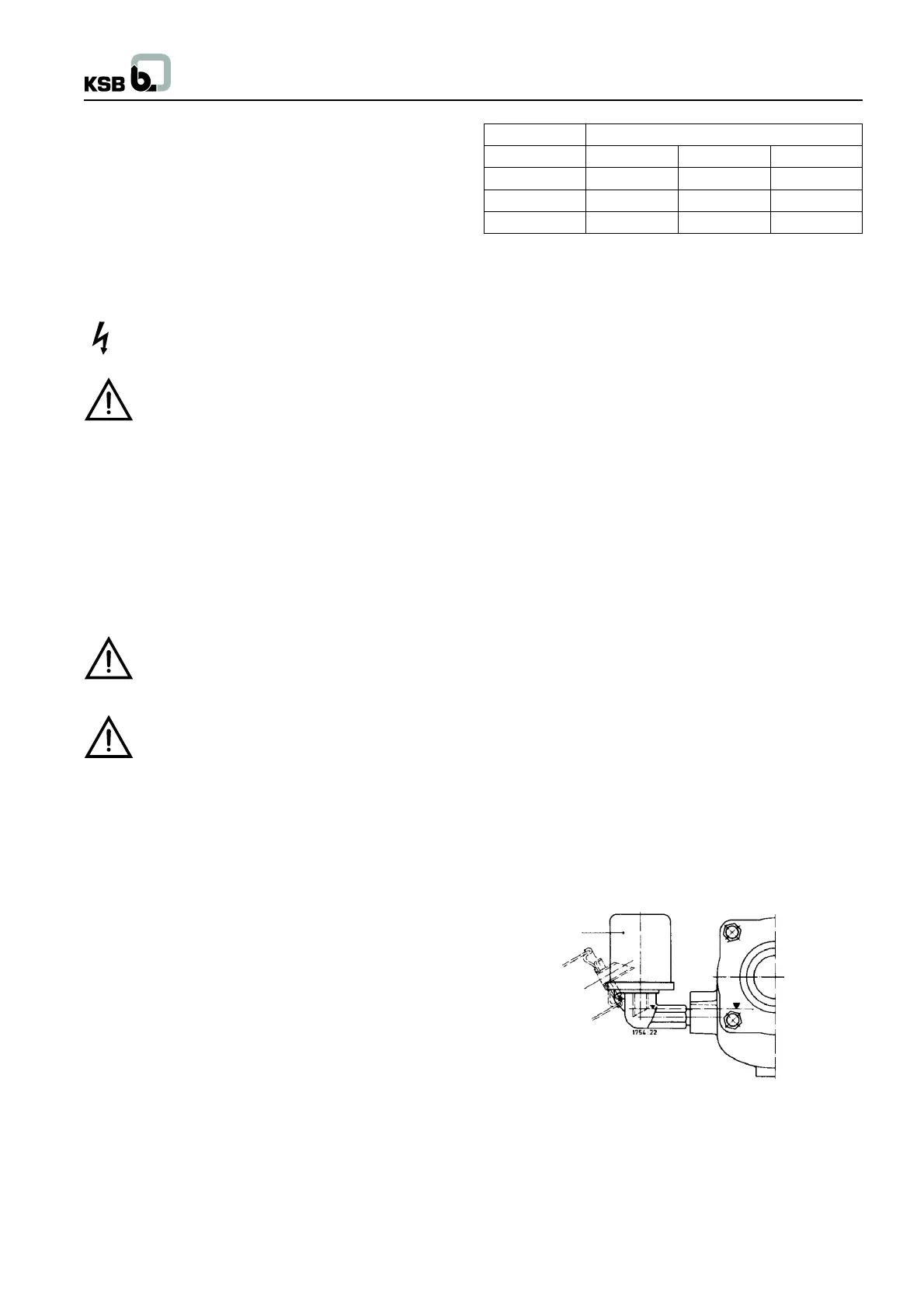

Unscrew the plug in the re-fill hole and the drain hole. After the

bearing housing has been drained completely, plug the drain hole

again.

638

Fig. 7.2-1 Oil fill

11

Loading...

Loading...