Multitec

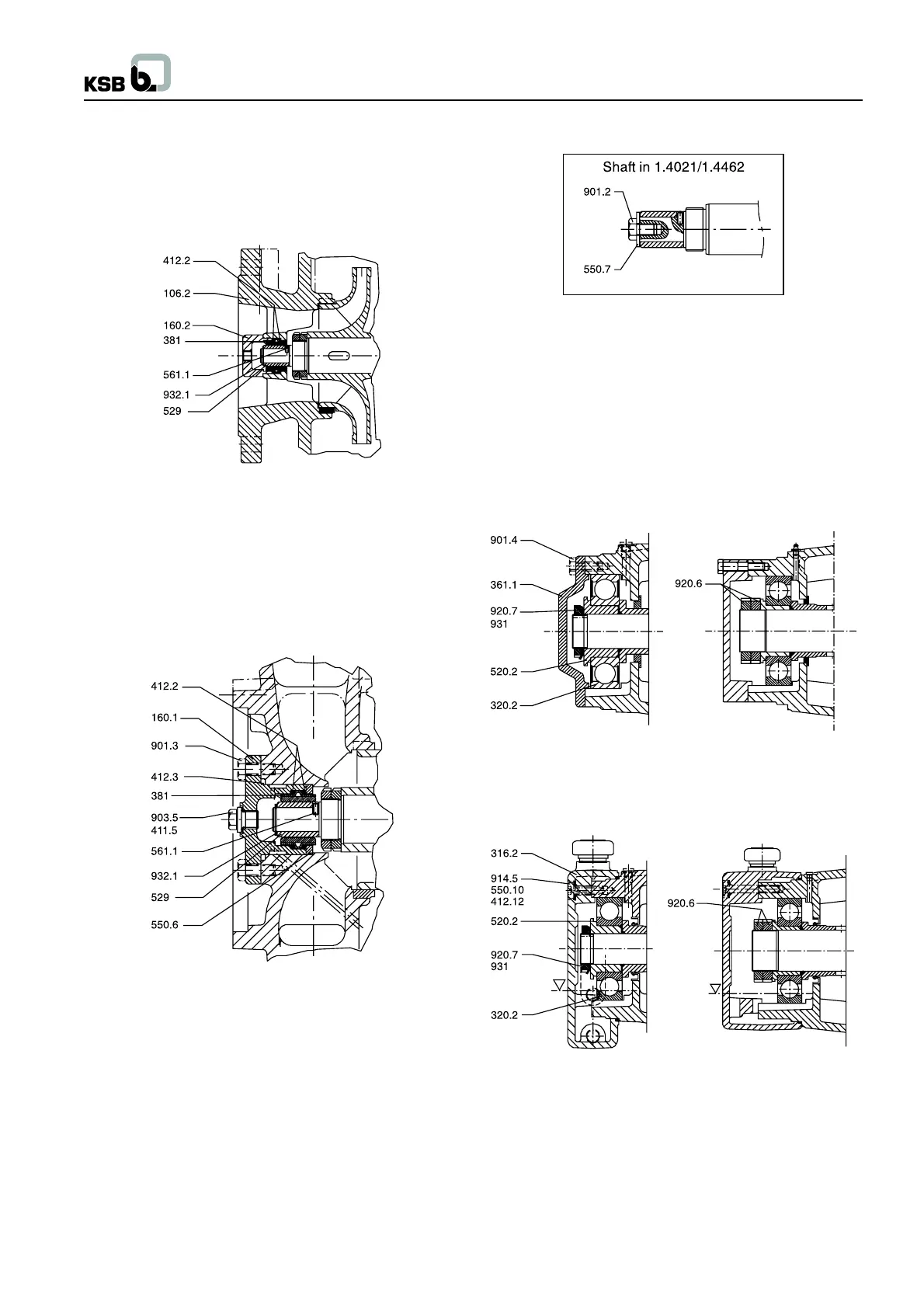

Fig. 7.3-1

- Pull off bearing cover 160.2 using forcing screws.

- Remove circlip 932.1 (shaft in C45) or bolt 901.2 and disc

550.7 (shaft in 1.4021 / 1.4462).

- Take out bearing sleeve 529.

- Pull out bearing cartridge 381 with its two O-rings 412.2

N.B.: The anti-torsion pin 561.1 remains in position.

Radial suction nozzle :

Fig. 7.3-2

- Undo bolts 901.3 and remove cover 160.1 with O-ring 412.3

and bearing cartridge 381 with O-rings 412.2.

- Remove circlip 932.1 (shaft in C45) or screw 901.2 and disc

550.7 (for shafts in 1.4021/1.4462)

- Take out bearing sleeve 529

- Remove disc 550.6

N.B.: The anti-torsion pin 561.1 remains in position.

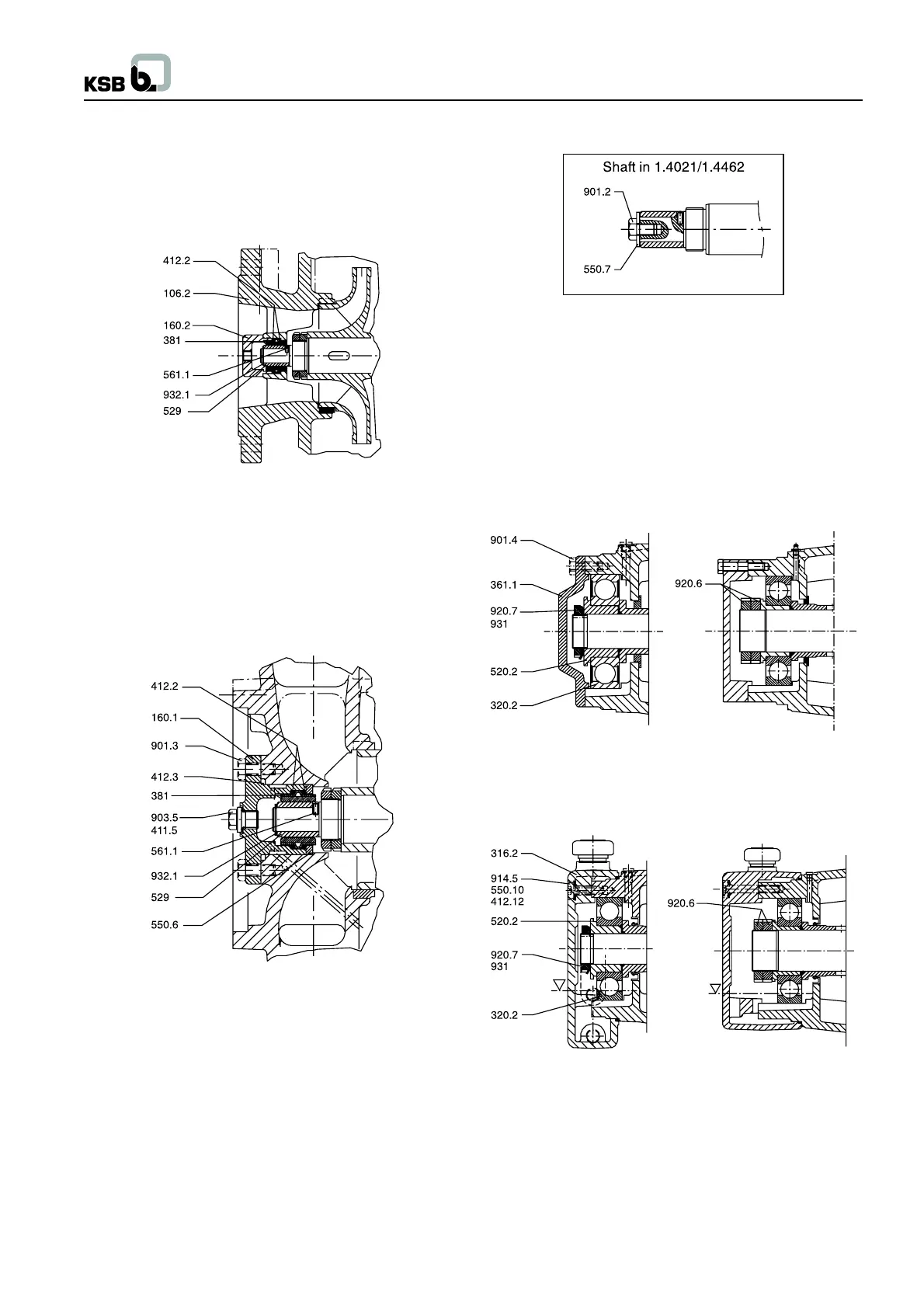

Fig. 7.3-3

Rolling element bearings :

If the pump is oil-lubricated, drain the oil before dismantling.

- Unscrew bolts 901.4 or 901.9 and remove non-drive end

bearing cover 361.1 or 361.2.

- Unscrew nut 920.7 with lockwasher 931 or the nut with

castellated nut 920.6.

- pull out sleeve 520.2 with rolling element bearing 320.2.

Grease lubrication

Multitec 32 - 125 Multitec 150

Fig. 7.3-4

Oil lubrication

Multitec 32 - 125 Multitec 150

Fig. 7.3-5

13

7.3.3.1 Dismantling the Non-Drive-End Bearings

Plain bearing

The plain bearing is removed without dismantling the hydraulic

system of the pump.

Axial suction nozzle :

Loading...

Loading...