Multitec

5.3.1 Aligning the Pump / Drive

Coupling guard

In compliance with the accident prevention

regulations the pump must not be operated without

a coupling guard / a guard on the drive lantern. If the customer

specifically requests not to include a coupling guard / lantern

guard in our delivery, then the operator must supply one.

Baseplate-mounted units

After fastening the baseplate on the foundation, the

coupling must be thoroughly checked and the pump

unit be realigned (at the motor), if required.

Prior to checking the alignment/realignment, loosen the pump

feet and retighten without transmitting any stresses or strains.

Coupling check and realignment must be effected

even if pump and motor are supplied completely

assembled and aligned on a common baseplate.

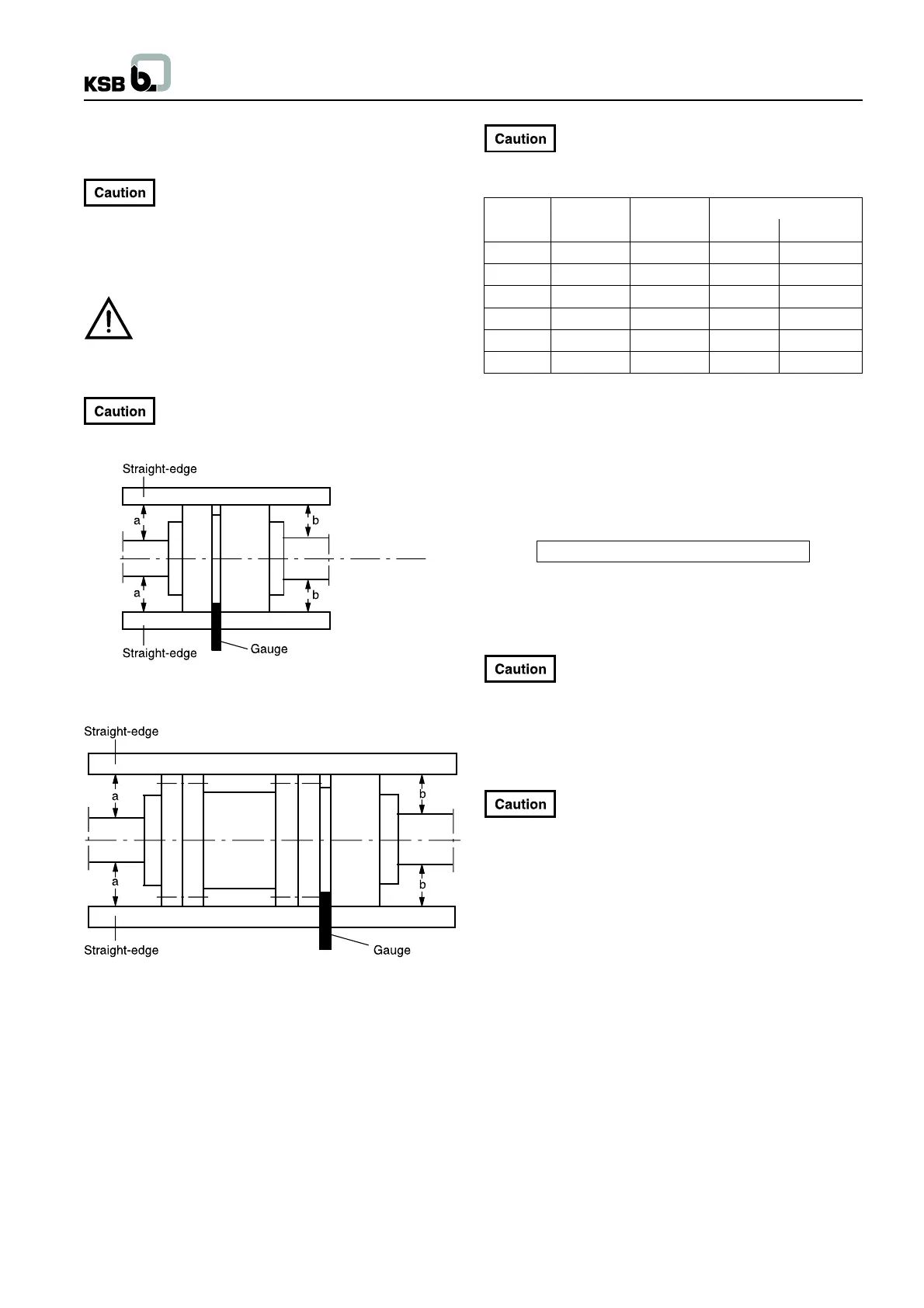

Fig. 5.3-3 Aligning the coupling with the help of a gauge

and straight-edge

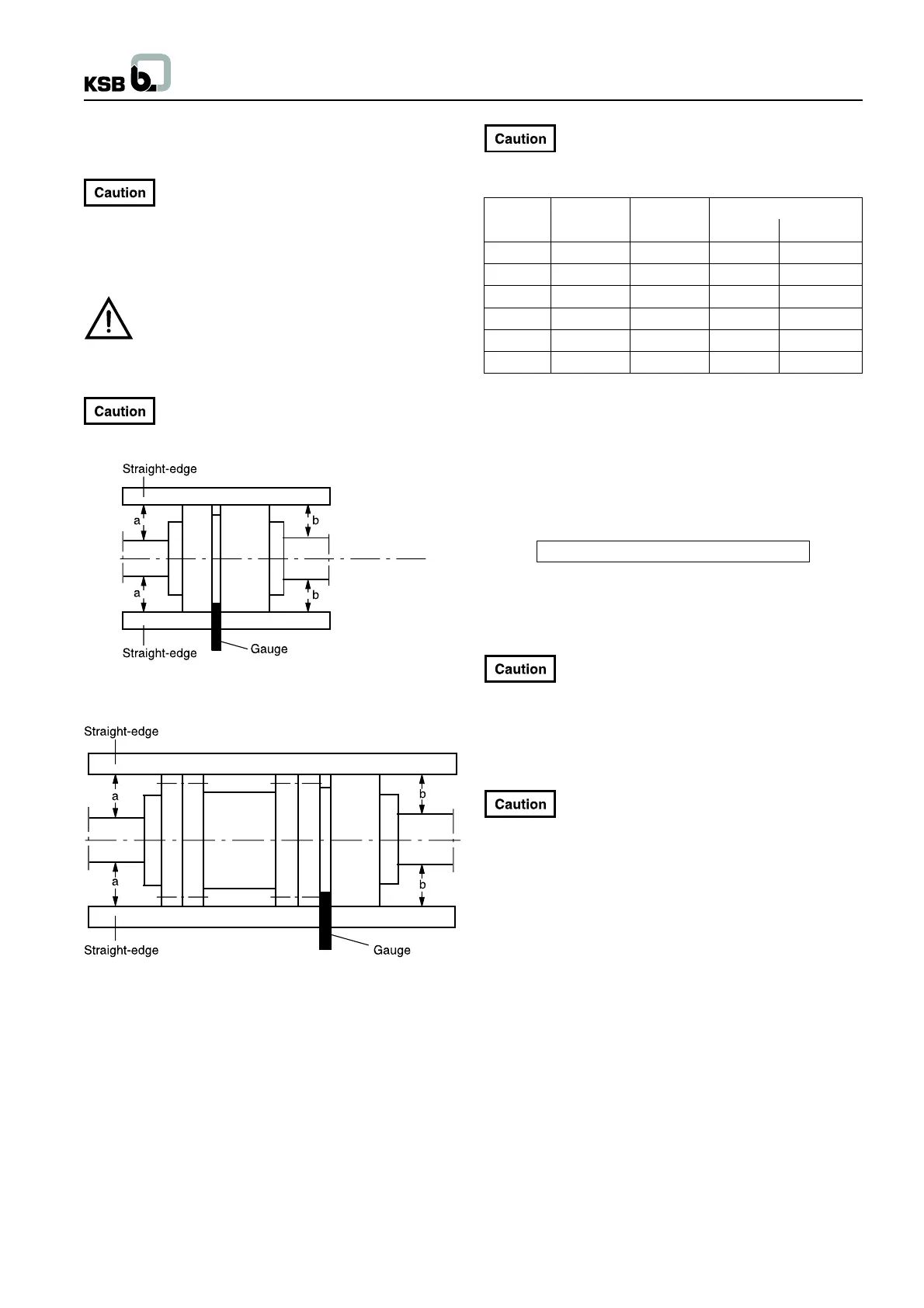

Fig. 5.3-4 Aligning a spacer-type coupling

The radial and axial deviation between the two coupling halves

shall not exceed 0.1 mm.

For product temperatures of 120

0

C and higher, the

foot bolts to secure the pump on the baseplate are

to be tightened with torques according to the following table :

MTC Thread Strength

Torque

drive non-drive

32 M 12 4.6 30 Nm 15 Nm

50 M 12 4.6 30 Nm 15 Nm

65 M 16 4.6 60 Nm 30 Nm

100 M 20 4.6 120 Nm 60 Nm

125 M 20 4.6 120 Nm 60 Nm

150 M 30 4.6 450 Nm 200 Nm

This will avoid that longitudinal increase of the pump by thermal

expansion will lead to warping and deformation.

As the thermal expansion in height of pump and motor may differ,

this has to be considered when aligning the coupling of pump

units handling temperatures of 100

0

C and higher. To estimate

the increase in height, the following equation can serve as a guide

to calculate by how much the motor has to be elevated in

relationship to the pump :

H [mm] = 1/100000 * (Tp * Hp - Tm * Hm)

Tp = Temperature difference pump - environment (

0

C)

Hp = Height of pump axis [mm]

Tm = Temperature difference motor - environment (

0

C)

Hm = Height of motor axis [mm]

In any case, also when using this correction, the

coupling has to be re-aligned when the unit is in

warm condition from operation.

Close-coupled pumps and vertical pumps

Alignment between the motor and the pump is ensured by the

centering effect between the motor flange and the drive lantern

flange. It must be easy to rotate the shaft.

For the Multitec V32-65, the dimensions for the

setting of the coupling alignment have to be

considered during assembly (see page no. 31).

Final check

Re-check the alignment as described in the sections above. It

must be easy to rotate the shaft by hand at the coupling. Check

the integrity and proper functioning of all connections.

5.4 Connecting the Piping

Suction lift lines shall be laid with a rising slope towards the pump

and suction head lines with a downward slope towards the pump,

to avoid the formation of air pockets.

With short pipelines, the nominal diameters shall be at least equal

to the nominal diameters of the pump nozzles. For long pipelines

the most economical nominal diameter has to be determined from

case to case.

Adapters to larger diameters should have a diffuser angle of

approx. 8 in order to avoid any pressure losses caused by of air

pockets or gas.

It is recommended to install check and shut-off elements in the

system, depending on the type of plant and pump.

5

Loading...

Loading...