Multitec

7.4.1 Tightening Torques - Tie Bolts 905

Material codes 10, 11, 12 (casing : cast iron)

Pump size Tightening torque (Nm)

Multitec 32 85

Multitec 50 140

Multitec 65 250

Multitec 100 395

Multitec 125 600

Multitec 150 700

Material codes 20, 21, 22, 23, 30

(casing : steel or stainless steel)

7.4.2 Reassembly of Hydraulic System

Pump reassembly starts at the suction side and proceeds

towards the discharge side. It is advisable to place the pump in

vertical position for reassembly. The sequence of reassembly

does not pose special problems and should be done according

to detailed sectional drawings showing the list if individual parts.

The components shall be re-installed in the same place as before

dismantling.

A clearance of 0.7 to 1.2 mm shall be set between the last impeller

230.1 or 230.3 and the balance drum 59-4 (or spacer sleeve

525.4).

- Tighten the nuts of the tie bolts 905 gently, with the pump in

vertical position.

- Place the pump in horizontal position upon its feet on the

assembly table.

- Tighten the nuts of tie bolts 905 in two steps (first step : 50%

of nominal torque, second step : nominal torque) in the

sequence 1.4.2.3.

Fig. 7.4-1

7.4.3 Seals

Gland packing

Before re-packing, thoroughly clean the gland packing chamber

and the gland cover.

Packing rings must be inserted so that the cut edge

is displaced by approx. 9_to 120_in relation to the

previous one.

Slip the prestressed packing rings onto the shaft protecting sleeve,

press home the first packing ring with the help of the gland

follower. Each packing ring must be pressed into the packing

chamber individually, using the gland cover.

For gland packings with lantern ring (for use in vacuum operation),

the lantern ring is mounted instead of the next to last packing

ring (the last packing ring is located in the seal chamber on the

pump size).

The gland cover must be tightened by hand at first. Use a feeler

gauge to check the level position of the gland cover. It must be

easy to rotate the rotor by hand.

Leakage is normal during pump commissioning. After approx. 5

minutes’ operating period, the amount of leakage can be reduced

by steadily tightening the nuts of the gland cover by 1/6 of a turn.

Keep an eye on the amount of leakage and the water temperature.

It takes several hours of pump operation for the gland to be

adjusted completely. There must be a high leakage rate during

the running-in period.

Repeat this procedure every five minutes until a minimum value

is reached.

Pump size Operating pressure Tightening torque

(bar) (Nm)

Multitec 32 150

Multitec 50 240

Multitec 65 All 430

Multitec 100 680

Multitec 125 1370

Multitec 150

< 40 1500

> 40 2000

Dimensions in mm Pump size

32 - 50 - 65 100 125 150

Packing cross-

10 o 12.5 o 16 o

section

Length of packing

~ 181 ~ 223 ~ 243 ~ 306

cord

Number of packing

5 6

rings

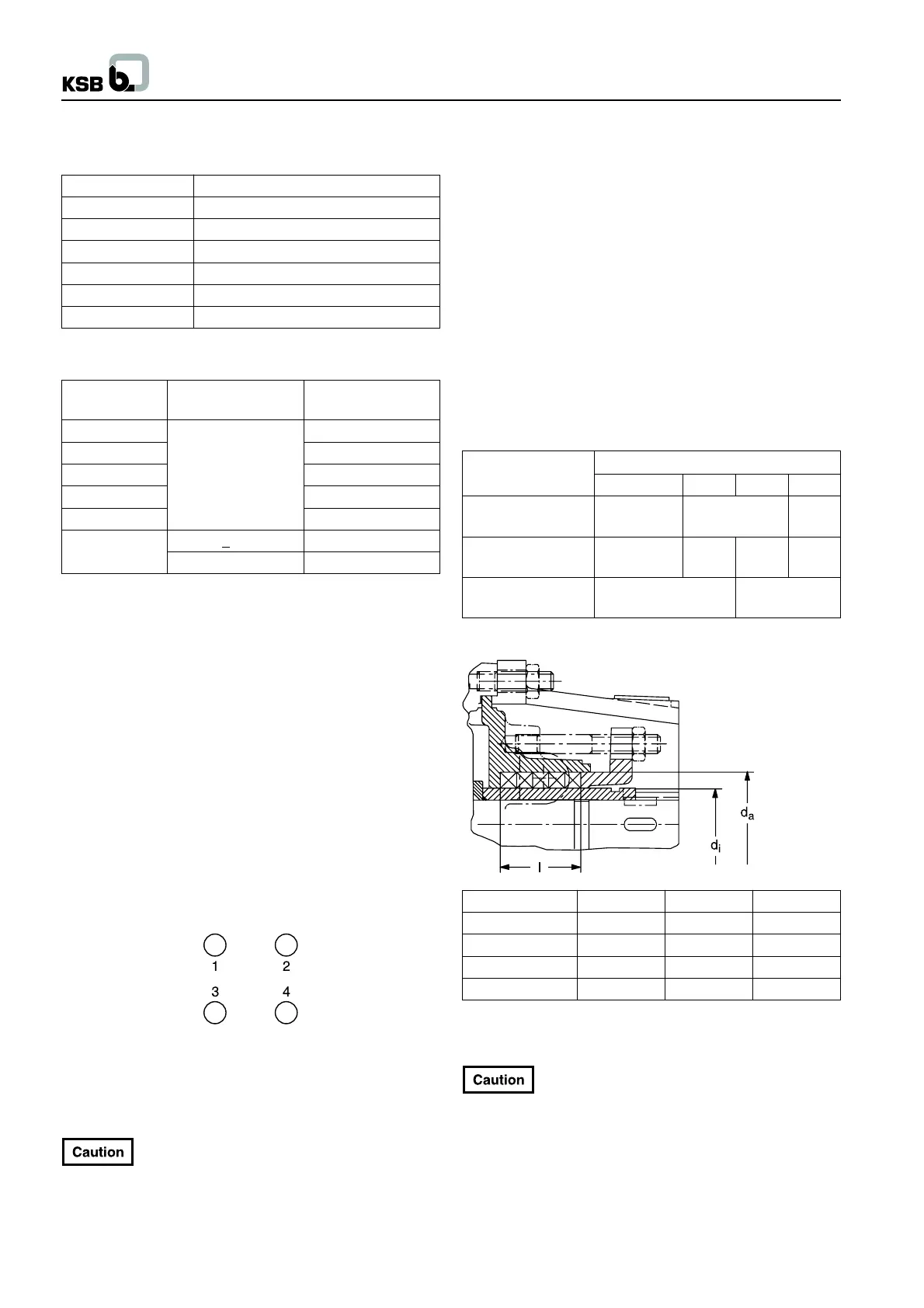

Gland housing

Pump size di da I

32 - 50 - 65 45 65 50

100 56 80 60

125 66 90 72

150 78 110 96

Fig. 7.4-2 Gland chamber dimensions

Mechanical Seals

Mechanical seals are precision components. The

seat ring and the spring-loaded ring must always

be replaced together, i.e. always replace the entire mechanical

seal.

To ensure trouble-free operation of the mechanical seal. The seal

faces and any tools used must be absolutely clean. Mechanical

seals must be installed with utmost care.

The seal faces shall only be cleaned immediately before assembly

takes place. They must not be greasy (grease, smudges ...) or

damaged.

18

Loading...

Loading...