Multitec

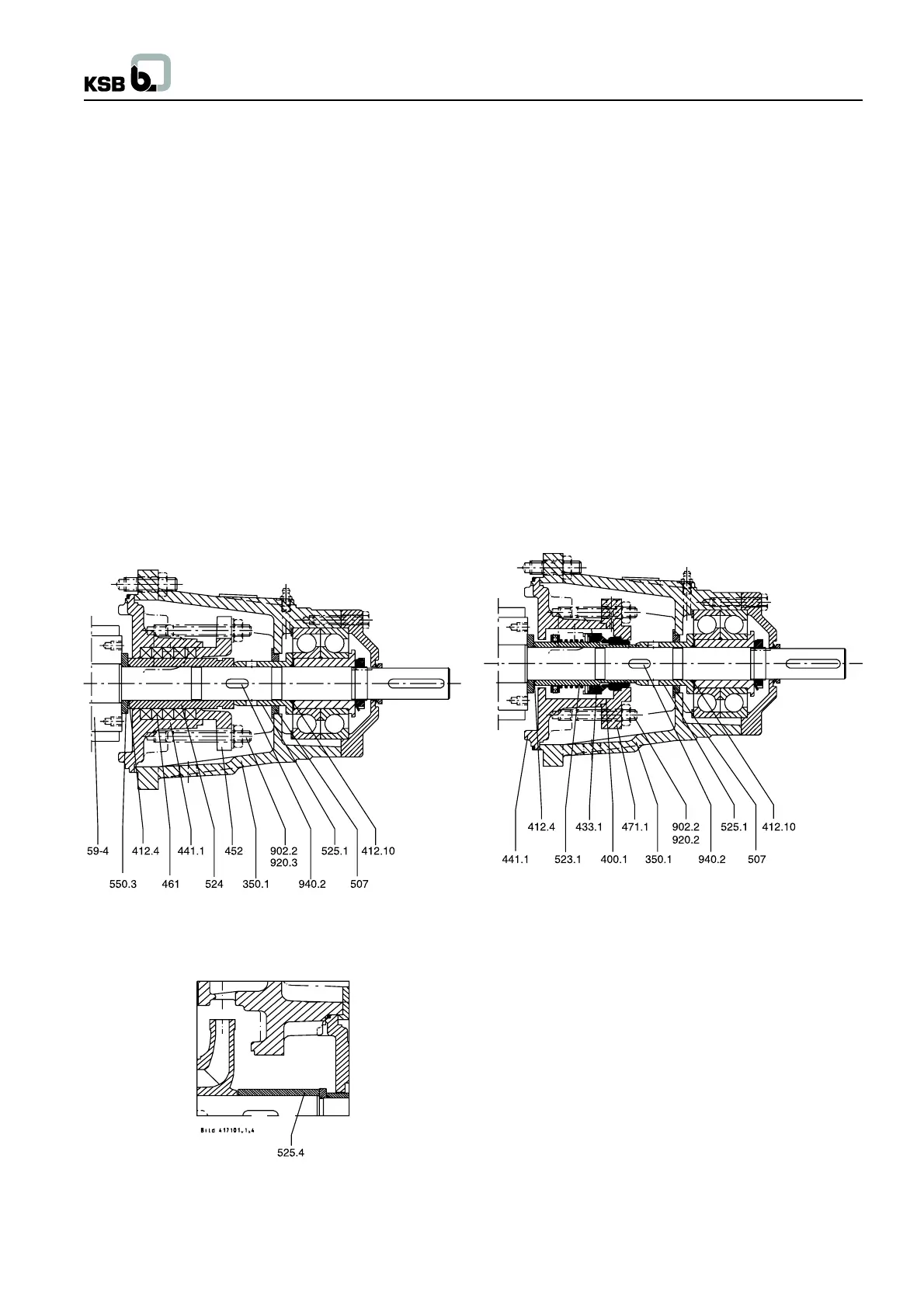

7.3.4.2 Replacing the Shaft Protecting Sleeve

- Remove the bearing as described in sections 7.3.3.1 and

7.3.3.2.

- Remove packing rings as described in section 7.3.4.1.

- Grease-Lubricated version pull V-ring 411.6 off spacer sleeve

525.1.

- Remove O-ring 412.10.

- Take off spacer sleeve 525.1.

- Remove bearing housing 350.1

- Remove the seal housing 441.1 together with gland cover

452.

- Remove key 940.

- Take off sleeve 524 with a pull-off device. Use the groove in

the sleeve to do so.

- Remove O-ring 412.4.

N. B.: If the sleeve 524 proves difficult to remove, the balance

drum can be used for leverage.

- Remove balance drum 59-4, disc 550.3 and sleeve 524 with

a pull-off device engaged in the threaded holes on the drum.

This is not possible on pumps without balance drum.

Fig. 7.3-7

Pump design without balance drum

Fig. 7.3-8

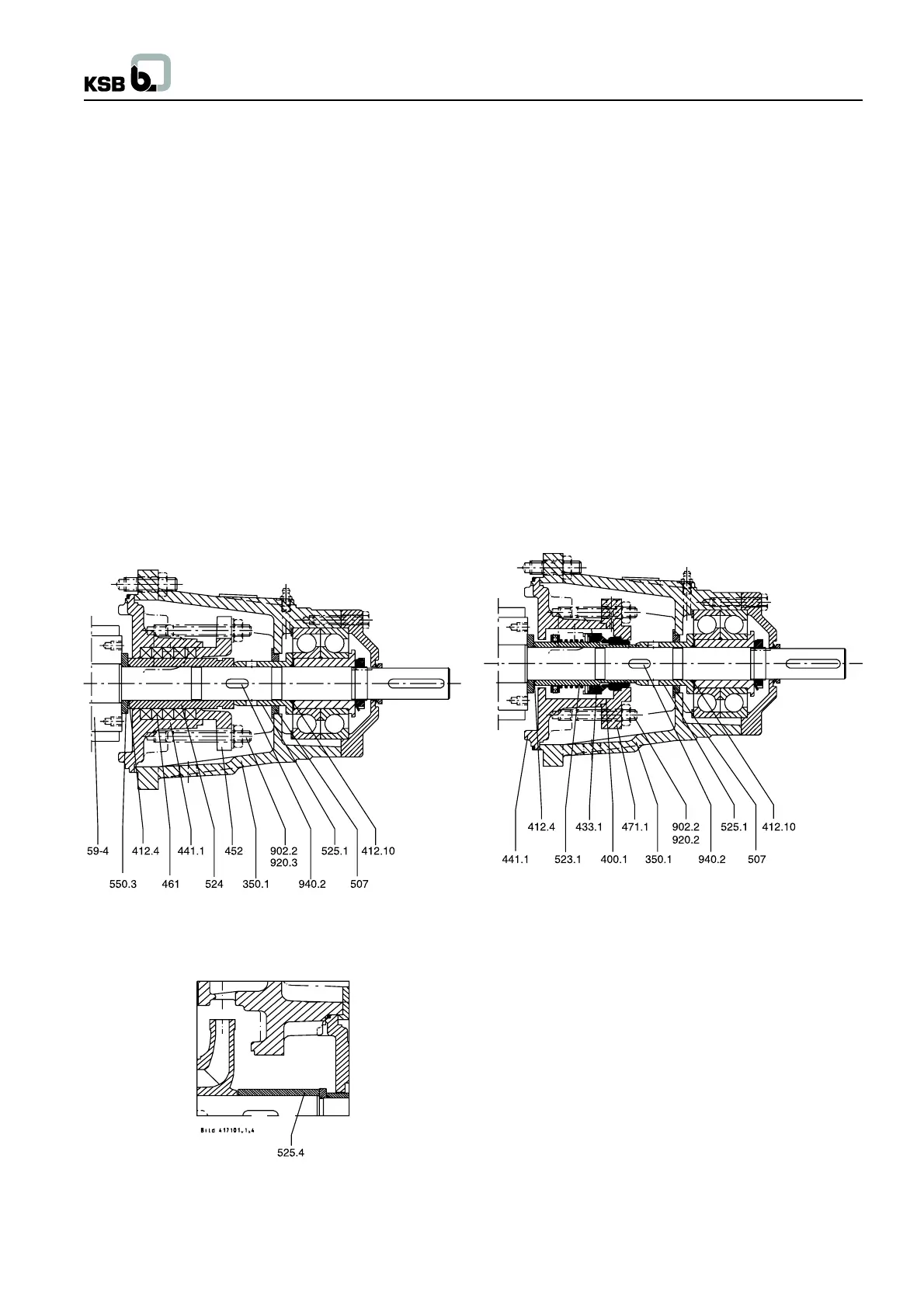

7.3.5 Removing the Mechanical Seal

- Remove the bearings as described in sections 7.3.3.1 and

7.3.3.2.

- For grease lubricated version pull V-ring 411.6 off spacer

sleeve 525.1

- Remove O-ring 412.10.

- Pull off spaces sleeve 525.1.

- Remove any auxiliary pipe work (circulation, etc.), depending

on the pump version.

- Loosen nuts 920.3 at the mechanical seal cover until the spring

is relaxed.

- Remove bearing housing 350.1.

- Take off mechanical seal cover 471.1 with the seat ring and

gasket 400.1, remove spring loaded ring (not in case of

bellows seal).

- Remove key 940.2.

- Pull off sleeve 523.1 with the rotating assembly of the

mechanical seal. (Two holes are supplied in the sleeve for

engaging a pull-off device.)

- Take off shaft seal housing 441.1

- Remove O-ring 412.4.

Fig. 7.3-9

15

Loading...

Loading...