Multitec

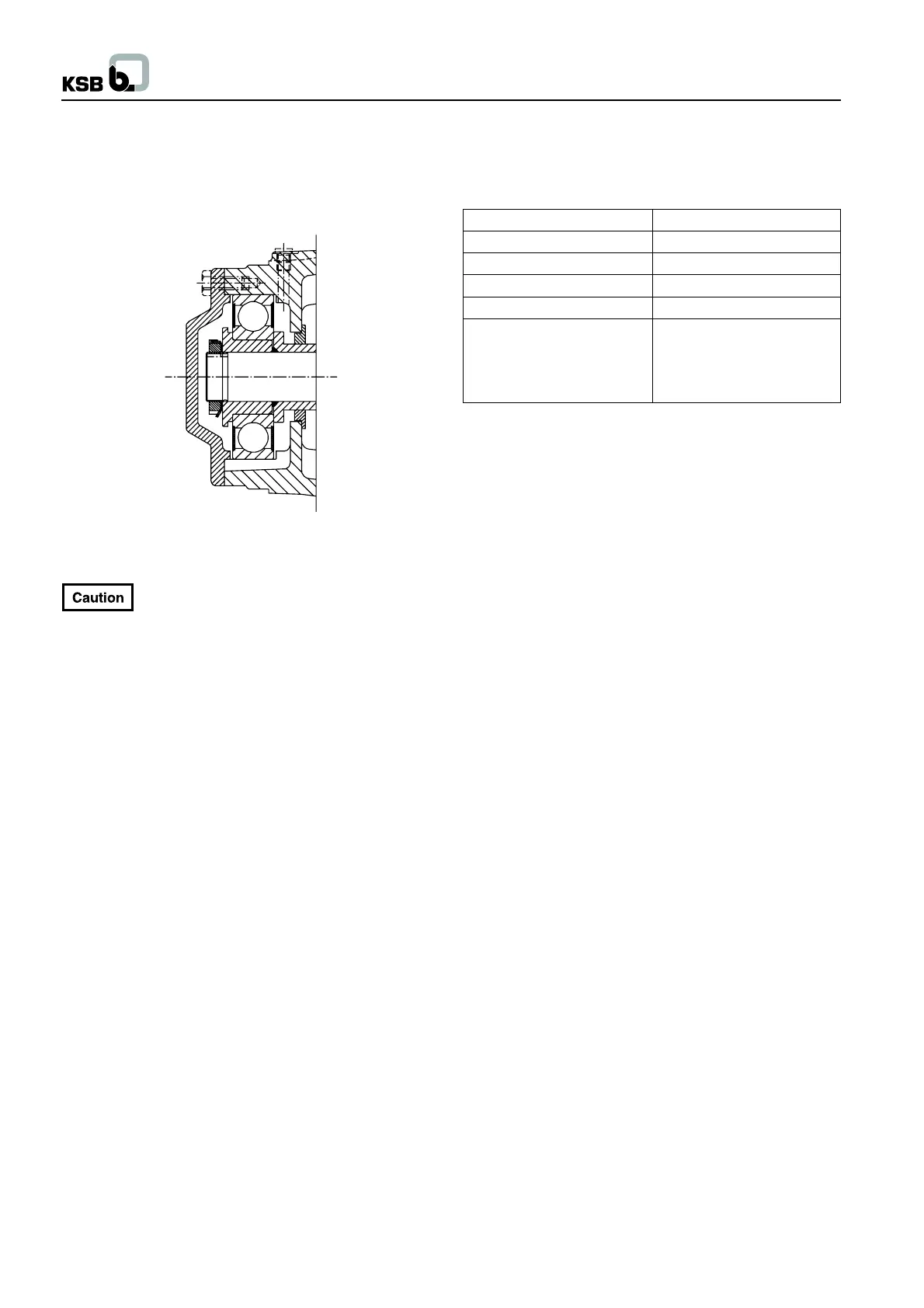

Radial bearings

Versions C and D are equipped with a deep-groove ball bearing

as radial bearing. (The other versions are fitted with a plain bearing

in the suction casing.) The outer race of the deep-groove ball

bearing must have axial play. The bearing is installed without

spacer discs 551.1.

Fig. 7.4-6

7.4.4.1 Temperature of the Rolling Element

Bearings

The temperature of the rolling element bearings,

which run at 3000 1/min and more, can be 90

0

C.

Manual temperature checks are not sufficient !

- The bearings only reach their normal operating temperature

after some hours of operation.

- When a new pump is started up, the bearing temperature may

exceed 95

0

C. After 2 or 3 operating hours, it will sink slowly

and level out to a constant value after approximately one week.

- A temperature rise may occur after service activities

comprising replacement of bearings or dismantling of

hydraulic system.

Should the temperature exceed 100

0

C during pump start-up,

switch off the pump and perform the following checks :

- Check whether the unit is correctly aligned.

- Remove the bearings, check grease quantity.

An excessive grease quantity will cause excessive

temperature.

- Check the bearing type and arrangement (see 7.4.4.4).

- Restart the pump. Ensure tight press fit between outer races

and cover (fixed bearing).

7.5 Re-adjusting the Clearance Gaps

7.5.1 Maximum Clearance Gaps

The following max. diameters of clearances apply :

D

Impellers 230 and 231

Suction side clearance gap 0.8 mm

Clearance gap at the hub 0.8 mm

Balance drum 59-4 0.8 mm

Suction casing 106.1 and 1.0 mm if the product is pumped

spacer sleeve 525.2 (only for From a vessel under vacuum

pump versions C and D) conditions

2.5 mm for all other operating

conditions

7.5.2 Repairs

Clearance between impeller 231 and suction casing :

Pump size 32 to 65 for material codes 10, 11, 12 :

Re-working the suction casing and mounting a spacer casing

wear ring as per ZN 1905 and re-working the impeller.

For other pump sizes and material codes :

Replacing the casing wear ring 521.1 by a spare ring as per ZN

1095 and re-working the impeller.

Clearance between impeller 230 and disc 550.1 resp. casing

wear ring 502.2 :

(Size 32 to 100) :

Various repair methods are possible :

a) Replacing the impellers 230 and discs 550.1 with new parts.

Quick repair method, no-rework of parts required.

b) Re-working the impellers at the impeller eye by deposit

welding and subsequently machining to the original diameter.

This repair method is used for impellers made of stainless

steel.

c) Re-working the impellers 230, re-assembly of stage casings

or diffusers (depending on the pump version) and replacing

the discs made of deep-drawn sheet metal by solid discs.

This repair method does not require KSB spare parts.

22

Loading...

Loading...