Multitec

The unit/pump is installed sometime before the plant is

commissioned :

Special measures have to be taken after a prolonged shutdown

period, e.g., to make sure that the pump is always ready for instant

start-up and to prevent the formation of deposits within the pump’s

hydraulic system and intake area.

These measures are described in section 6.3.1.

4. Description of the Product and

Accessories

4.1 Technical specification

Multistage centrifugal pumps in ring-section design with suction

impeller for low NPSH value (exception : MTC 32).

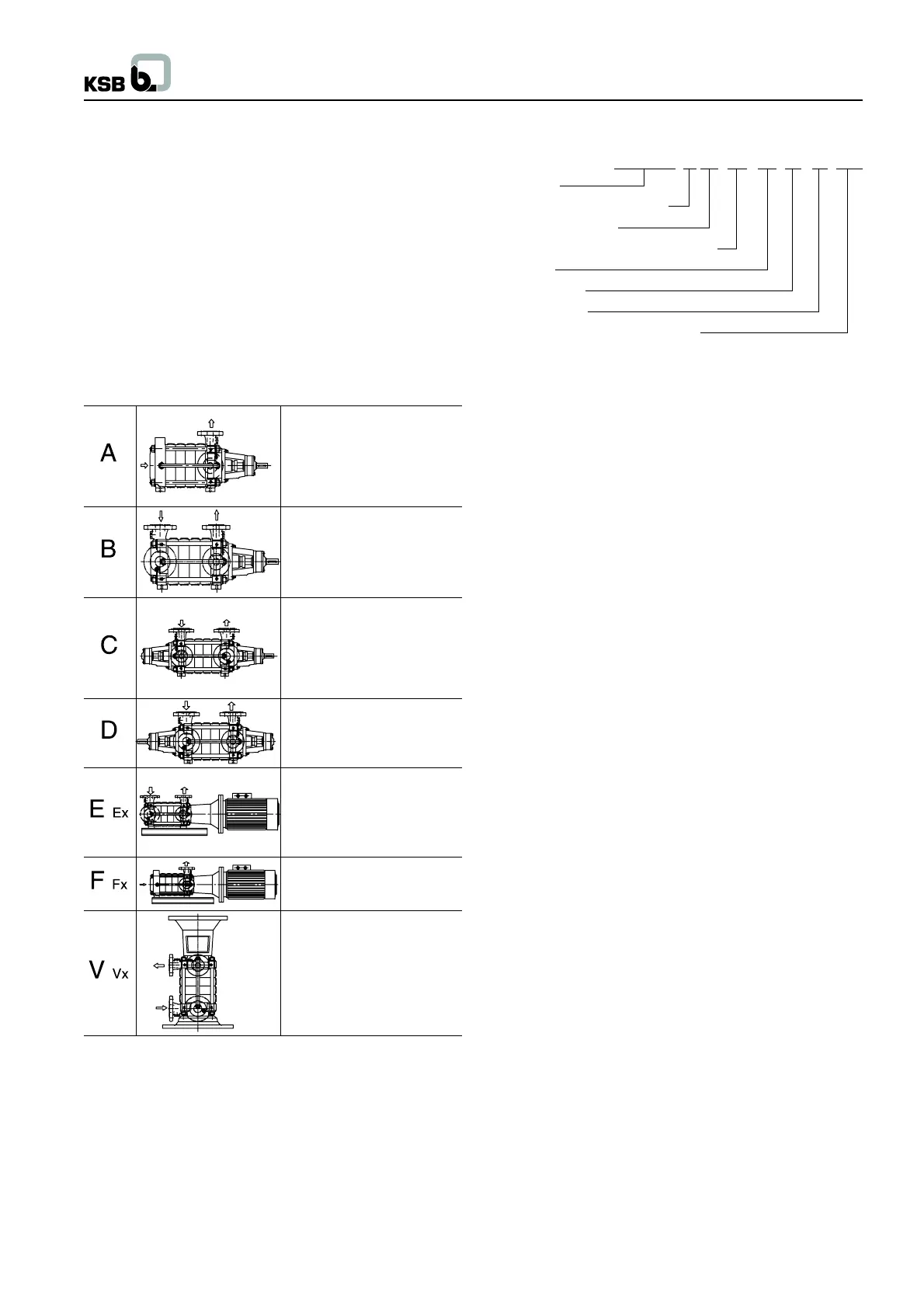

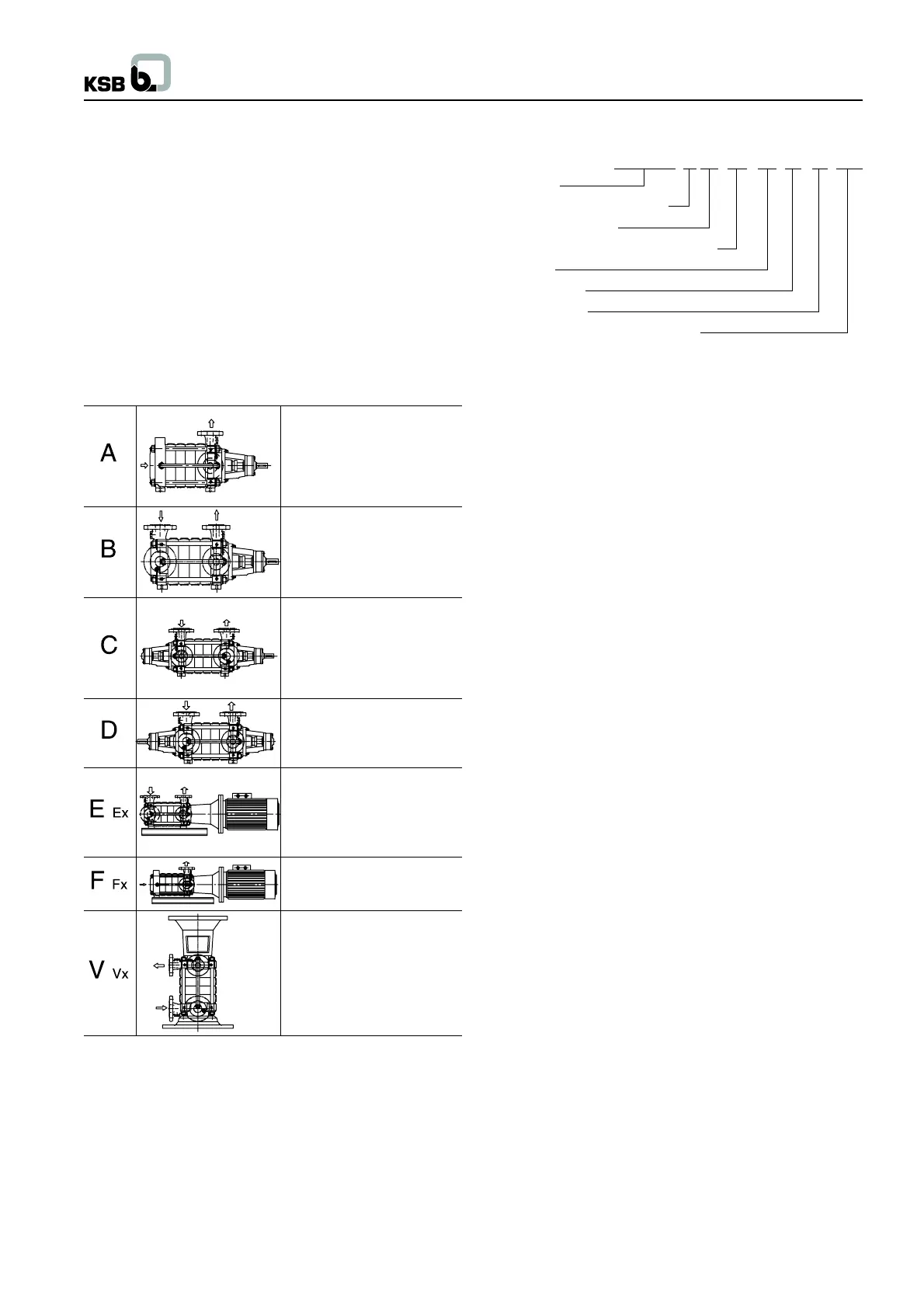

Horizontal design, baseplate mounted,

1 casing entry, drive end

1 rolling element bearing, drive end

1 plain bearing, suction end axial

suction nozzle

For the entire Q/H range

Same as installation type A, but

with radial suction nozzle

Horizontal design, baseplate

mounted 2 casing entires, drive

and suction end

2 rolling element bearings drive

on discharge side

For the entire Q/H range

Same as installation type C, but

drive on suction side

Horizontal close coupled pump,

Common bearing for pump and

motor rigid coupling,

radial suction nozzle,

Q/H range : up to 100 m

3

/h, 25 bar

Same as installation type E, but

with axial suction nozzle

Vertical close - coupled pump

Q/H range : up to 204 m

3

/h 25 bar

up to 100 m

3

/h 40 bar

4.2 Designation

Multistage A 32 / 8E - 2.1 12 . 65 (SP)

Type series

Installation type/pump version

DN discharge nozzle

Number of stages/impeller combination

Hydraulics

Material variant

Shaft seal code

Code for special variants (optional)

4.3 Design details

Design :

High-pressure centrifugal pump in long-coupled (baseplate

mounted) or close-coupled design, horizontal or vertical version,

axial or radial suction nozzle. Radial suction and discharge

nozzles can be turned by 90_.

Bearings :

Radial bearings made as silicon carbide plain bearings (not for

version C and D), self-aligning. Plain bearings lubricated by the

pumped product, fixed bearings made as rolling element bearing,

grease- or oil-lubricated.

Shaft seal :

Uncooled gland packing with or without sealing liquid feed.

Standardized mechanical seal to DIN 24 960, uncooled or cooled.

Double-acting mechanical seal with standardized mechanical

seals to DIN 24960 (back-to-back or tandem).

Drive :

Electric / Hydraulic drives or Diesel engines, or turbines up to

max. 4000 1/min.

4.4 Fields of Application

Municipal water supply :

Pumping stations, water treatment and pressure boosting plants.

Water treatment :

Filtration, reverse osmosis.

Pumps in industrial applications :

General water supply, cold water, washing systems, recycling,

cooling circuits, boiler feed systems, warm water, hot water,

condensate handling, process, organic and inorganic liquids,

degreasing agents, washing or alkaline solutions, lubricants,

cooling, surface treatment.

Air-conditioning :

large-scale air-conditioning systems, highrise buildings.

Irrigation :

Centre-pivot sprinkling systems, trickle irrigation systems,

square sprinkling systems, flood irrigation systems.

3

Loading...

Loading...