Multitec

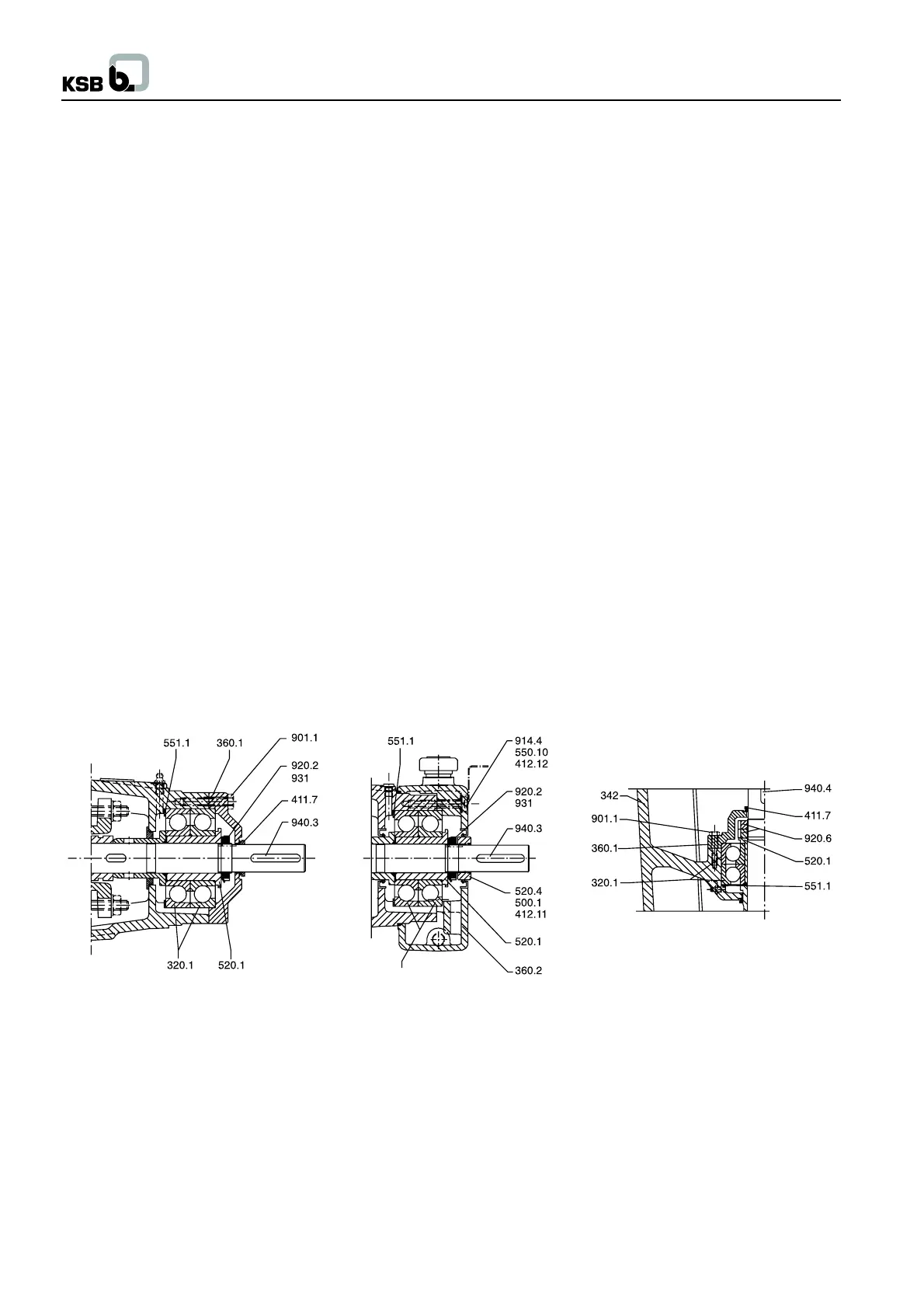

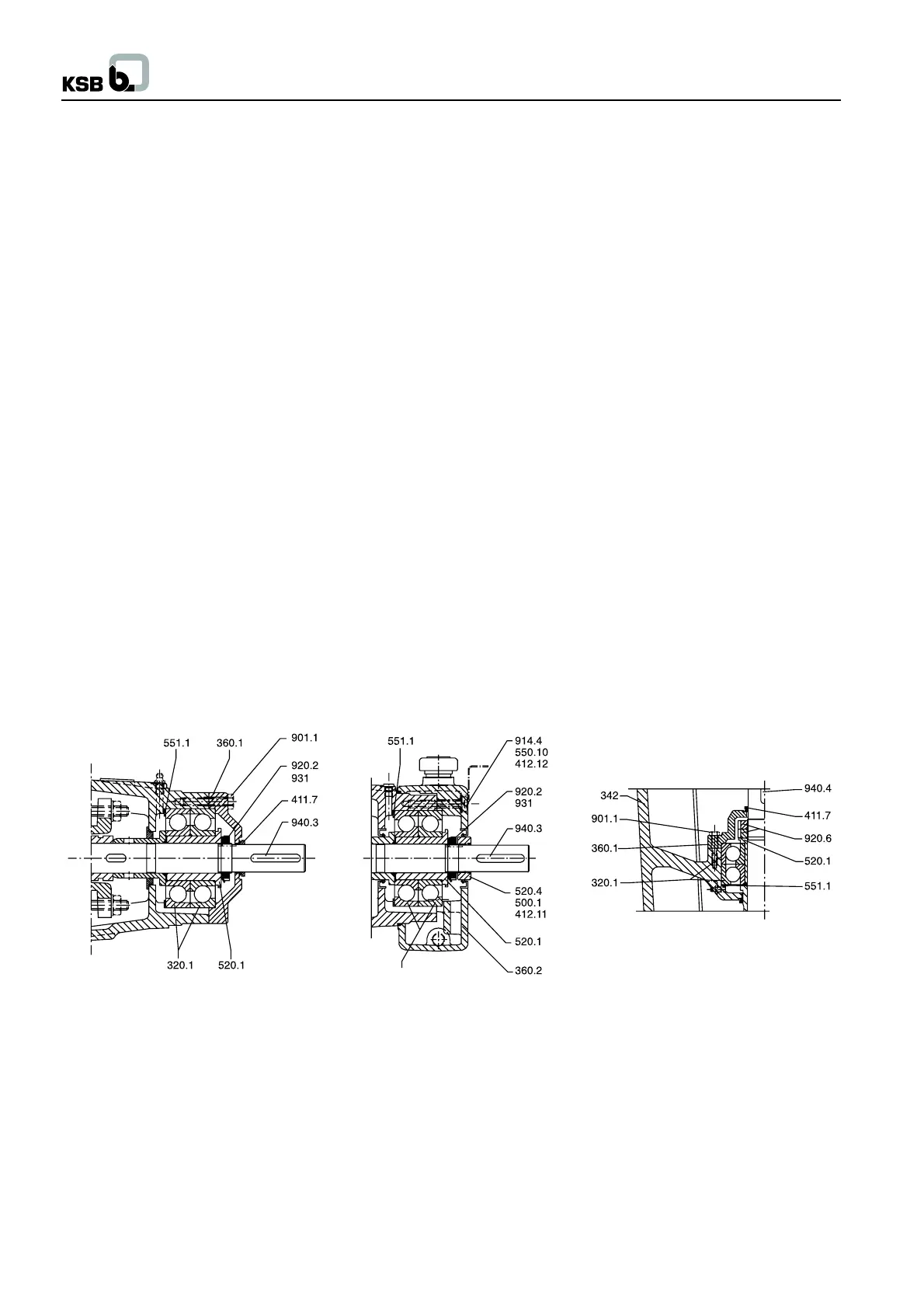

7.3.3.2 Dismantling the Drive-End Rolling Element

Bearings

N.B. : The ceramic plain bearing installed at the non-drive end

need not be dismantled in order to remove the drive-end rolling

element bearings. If the pump is oil lubricated, the oil must be

drained before dismantling.

- After loosening the grub screw in the coupling hub pull out

coupling half with key 940.3.

- Remove joint ring (V-ring) 411.7 (only for grease-lubricated

version).

- Undo bolt 901.1 (for grease-lubricated version)

- Loosen bolts 901.8 and pull out together with washer 550.10

and O-ring 412.12 (for oil-lubricated version).

- Remove bearing cover 360.1 or 360.2, depending on the pump

version.

- Remove sleeve 5220.4 with ring 500.1 (tolerance ring) and

O-ring 412.11 (only for oil-lubricated version).

The rotating unit is adjusted axially by means of spacers 551.1.

When reassembling the pump after partial dismantling (bearing

or seal modification), the same spacer discs 551.1 must be

mounted on the side of the bearing to reproduce the original rotor

adjustment (see also Section 7.4.4).

- Undo nut 920.2 with lockwasher 931 or nut with locknut 920.6,

depending on the pump version. To undo the nut, hold onto

shaft with key 940.3.

- Pull off shaft protecting sleeve 520.1 with rolling element

bearing 320.1 (The shaft is centered in the sleeve without

locking device.)

- Remove spacers 551.1, see text above.

N. B.: In the version V, Vx, E, Ex, F, Fx of sizes 32, 50, 65 the

pump does not have a fixed bearing as this function is being

taken over by the motor bearings. In the version Multitec V100,

V125 and V150 the fixed bearing is located in the support lantern

342. Dismantling and installation are the same as for the horizontal

versions.

Fig. 7.3-6

Grease lubrication Oil lubrication Design version V, Multitec 100/125

(only grease lubrication)

7.3.4 Dismantling and Replacement of Shaft

Seal

Gland Packings

7.3.4.1 Replacing the Packing Rings

Access to packing rings without removing the bearing of the

lantern :

- Undo both nuts 920.3 and pull gland cover 452 out of seal

housing 441.1.

- Remove packing rings 461.

14

Loading...

Loading...