Multitec

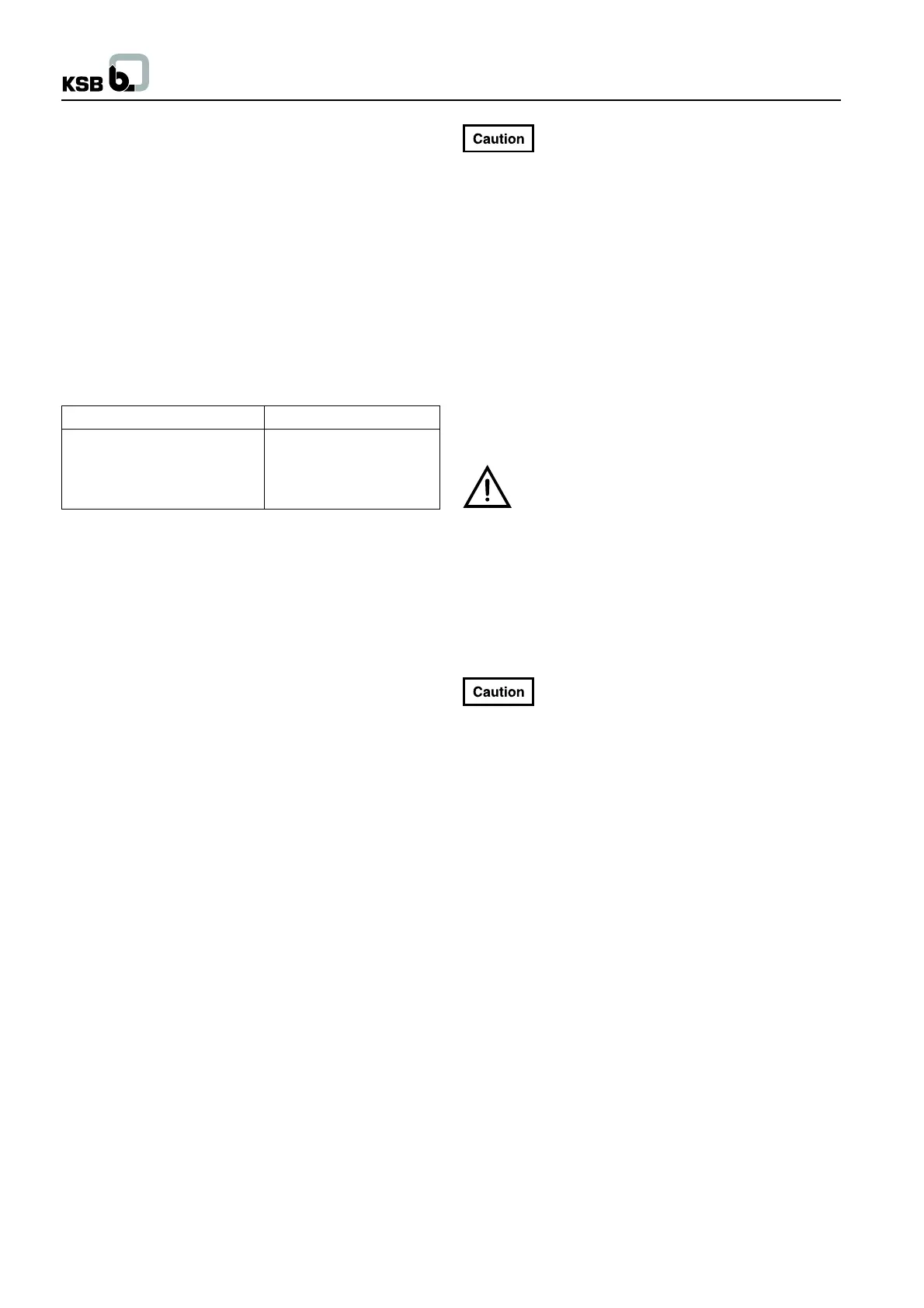

Motor rating (kW) Max. start-ups/h

up to 3 kW 20

from 4 to 11 kW 15

from 11 to 45 kW 10

45 kW and above 5

6.2.3 Minimum Flows

If the plant configuration is such that the pump might be operated

against a closed discharge-side shut-off valve, the following

minimum flows are required during the time.

t -10 to + 100

0

C 15% of Qopt

t > 100 to 140

0

C 20% of Qopt

t > 140 to + 200

0

C 25% of Qopt

Contact KSB if exact minimum flows have to be calculated.

The minimum flows indicated above are for single pump operation

and prevent a thermal or mechanical overload of the pump. In

case of parallel operation with pumps of identical or different

design higher minimum flows may be required in some cases, to

guarantee a stable operating behavior.

6.2.4 Density of the Medium Handled

The power input of the pump will increase in proportion to the

density of the medium handled. To avoid overloading of the motor

and the pump, the density of the medium must comply with the

data specified on the purchase order.

6.3 Shutdown / Storage / Preservation

6.3.1 The pump/unit remains installed; periodic

check of operation :

In order to make sure that the pump is always ready for instant

start-up and to prevent the formation of deposits within the pump

and the pump intake area, start up the pump set regularly once a

month or once every 3 months for a short time (approx. 5 minutes)

during prolonged shutdown periods. Follow the instructions for

commissioning (see 6.1).

For pumps of materials variants 10, 20 and 21 (cast iron), longer

shutdown periods have to be avoided especially when pumping

aggressive water qualities (high oxygen content). In this case,

the pumps should be left filled and the functional run should be

made at least every two days instead of in intervals of 1 to 3

months (see also 6.1.5).

In the event of frost and/or prolonged shutdowns, the pump must

be drained and protected against freezing and corrosion. To drain

the pump, open drain plug 6B.

6.2.2 Switching Frequency

The permissible number of start-ups in a given period of time

depends on the circumstances prevailing in the plant and the

operating conditions. Overloading of the motor may generally

result in :

- an bonormal increase in motor temperature exceeding the

temperature limit of the winding or the bearing grease.

- premature coupling wear

- a reduced service life of the pump components

- irregularities or malfunctions in the plant

To prevent abnormal temperature increases in the motor and

excessive loads on the motor, coupling, pump, seals and

bearings, the switching frequency must not exceed the following

number of start-ups per hour (h).

In the case of horizontal pumps, virtually complete

drainage of the stage casings of pumps in installed

condition can only ensured by opening the plugs on the stage

casings (option). If this is not possible, it is recommended to

remove the pump and to proceed according to chap. 6.3.2.

6.3.2 The pump is removed from the pipe and stored

Before putting the pump into storage carry out all checks and

maintenance work specified in sections 7.1. Then preserve as

follows :

Drain pump as completely as possible. For vertical pumps, this

can be done by opening the dry plugs on the suction casing. For

horizontal pumps, an almost complete draining can be achieved

through the draining holes on the stage casings (option) by

opening the respective closing plug. The drainage can also

achieved by having the pump brought into vertical position with

the aid of a crane, with the suction nozzle pointing down, while

turning the rotor by hand. However, in addition, the seal chamber

still has to be drained by opening the respective drain plug.

When utilising lifting equipment, care must be taken

that the pump does not slip out of the suspension as

otherwise there is a risk of personal and material

damage! If a complete draining is not possible, it is recommended

to dismantle the pump and to dry the individual parts. Afterwards,

will the pump with a water-repellent preservative, e.g. RUSTELO

DEWATERING 924 (manufacturer CASTROL), OSYRIS DW

(manufacturer TOTAL) or equivalent. The pump shall be turned

by hand several times in order to ensure even distribution of the

preservative. Then drain the pump and close the suction and

discharge nozzle. Exposed blank metal parts are to be treated

with a suitable anti-corrosive agent.

If the pump must be preserved for a longer storage

period with KLUBERTOP K 01-601 or with another

preservative on the basis of glycol, the preservative must not be

drained. In this case, the pump must be filled completely with the

preservative for storage. The preservative has to be drained

before the pump is returned to operation. It can be re-used. Before

re-use, it should be made sure that the water content in the

preservative does not exceed 20%.

6.4 Returning to Service after Storage

Before returning the pump to service, carry out all instructions

laid down in the sections on “Commissioning” (6.1) and “Operating

Limits” (6.2).

Upon completion of the work, all safety-related and protective

equipment must be properly refitted and/or reactivated before

starting the pump set.

10

Loading...

Loading...