Multitec

5. Installation at Site

5.1 Safety regulations / Special instructions

Electrical equipment operated in hazardous locations must

comply with the explosion protection regulations. This is

indicated on the motor rating plate. If the equipment is

installed in hazardous locations, the applicable local explosion

protection regulations and the regulations of the test certificate

supplied with the equipment and issued by the responsible

approval authorities must be observed and complied with. The

test certificate must be kept close to the location of operation for

easy access (e.g. foreman’s office).

Centrifugal pumps will only give trouble-free operation

when carefully installed and maintained.

N.B.: The pump’s nameplate shown the type series, pump size,

version, product number, main operating data and the works

number (see also 4.2).

Please quote the type series / version in all queries, repeat orders

and particularly when ordering spare parts.

Fig. 5.1-1 Nameplate

This pump / unit must not be operated beyond the limit

values specified on the nameplate for capacity, speed

and temperature or other instructions laid down in this

manual or in the contract documentation. Any data stipulated for

the electrical connection of the unit and instructions for

maintenance and installation must be adhered to without fail.

Operation beyond the conditions indicated above will lead to

overloads the unit cannot withstand.

Trained personnel is essential to ensure trouble-free operation

of the unit.

KSB will not accept any responsibility for the safe and reliable

operation of the pump unit if these operating instructions are not

complied with.

In case of damage or if you need further information, please

contact KSB’s nearest customer service centre.

5.2 Foundation/Checks to be carried out prior to

installation

All structural work required must have been prepared in

accordance with the dimensions stated in the dimension table /

installation plan.

The concrete foundations shall have sufficient strength (min. BN

15) to ensure safe and functional installation in accordance with

DIN 1045 or equivalent standards.

Make sure that the concrete foundation has set firmly before

placing the unit on it. Its surface shall be truly horizontal and

even.

5.3 Installing the Pump / Unit

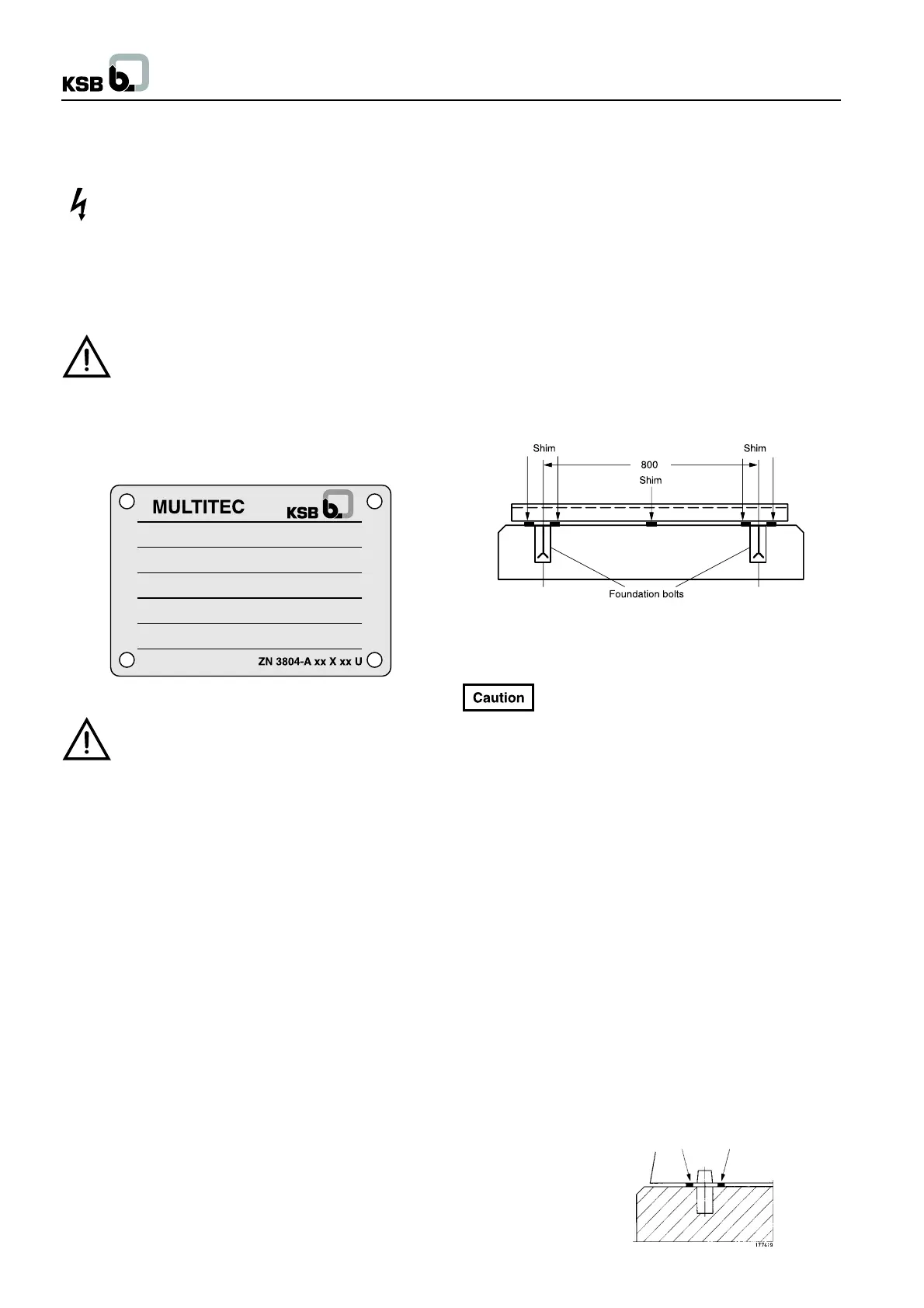

Before placing the baseplate onto the foundation, make sure that

the concrete foundation is clean and smooth. The complete pump

unit must be aligned horizontally with the help of a precision spirit

level.

Factory alignment of the unit on the baseplate must be re-aligned

after the unit has been mounted on the foundation and after

connecting the piping (precision alignment).

Align the complete pump unit with the help of spirit level placed

on the shaft/discharge nozzle. The correct distance between the

coupling halves as specified in the installation plan must be

observed. Shims shall be fitted between the baseplate / foundation

frame and the foundation itself; they shall always be inserted to

the left and right of the foundation bolts and in close proximity to

these bolts. For a bolt-to-bolt clearance of more than 800 mm,

additional shims must be inserted halfway between the adjoining

holes. All shims must lie perfectly flush.

Tighten the foundation bolts evenly and firmly after the concrete

has set.

It is essential to make sure that the baseplate is

not warped in axial or radial direction.

Proceed with utmost care when aligning the unit, as the pump

unit will only give trouble-free operation when correctly aligned.

Non-compliance with these instructions will lead to forfeiture of

all warranty claims.

Baseplates made of U-rails (up to 400 mm wide) are torsion

resistant in their own right and need not be grouted.

After fastening, baseplates more than 400 mm wide shall be

grouted up to the upper frame edge using low shrinkage concrete,

making sure that no cavities remain.

Close-coupled pumps

It is essential to make sure that the pump is not warped in axial

or radial direction.

If pump and motor are supplied separately, place the pump onto

the foundation without the motor, align with the help of a precision

spirit level (on the upper flange of the drive lantern), then fasten.

Shims shall be fitted between the pump foot and the foundation

itself; they shall always be inserted to the left and right of the

foundation bolts and in close proximity to these bolts. All shims

must lie perfectly flush.

Tighten the foundation bolts evenly and firmly.

Fig. 5-3-1 Fitting required shims

Shim

Fig. 5.3-2

Fitting required shims

4

Loading...

Loading...