Multitec

Individual seal components such as O-rings made of EPDM must

never come into contact with oil or grease.

The mechanical seal shall be re-assembled in the reverse

sequence of dismantling.

When mounting the seat ring, the shaft sleeve may be wetted

with clean medium handled to reduce the friction forces.

The seat ring and the spring-loaded ring shall always be mounted

by hand resp. fingers, making sure that pressure is applied

evenly, without tipping.

Horizontal baseplate - mounted pumps

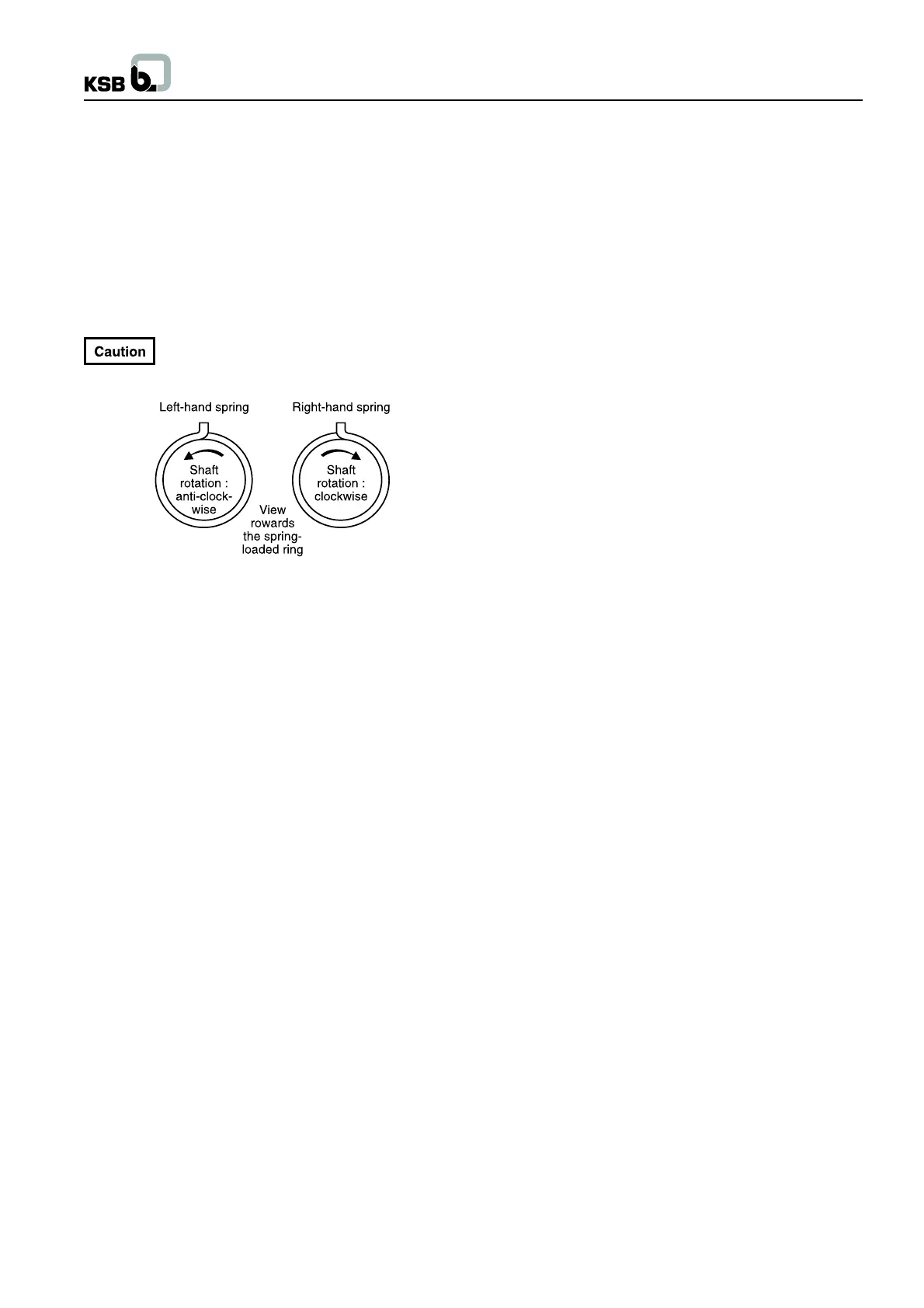

On pump versions C and D, the rotational direction

has to be observed for mechanical seals fitted with

uni-directional springs.

Fig. 7.4-3

7.4.3.1 Leakage at the Mechanical Seal

- Check axial alignment of the seal.

- Check gasket 400.01.

- Remove seal cover 471.1 (471.2 for bellows seal) and check

position of seat ring in the cover.

- Check the O-ring on shaft sleeve 523.1.

- Check O-ring 412.4.

7.4.4 Bearings

Plain bearings

In installation types A, B, E, Ex, F, Fx, V, Vx are re-installed in

reverse order to dismantling.

Rolling element bearings

The rolling element bearings are generally mounted on a bearing

sleeve and tightened with the shaft nut 920.2 / 920.6 / 920.7.

They are re-installed in reverse order to dismantling.

Check the concentricity and face run-out of ring 500.1 with a dial

gauge for variants with oil lubrication.

Sealing elements

Sealing elements made of EPDM must never come into contact

with oil or grease.

Defective O-rings (which have sustained mechanical damage

such as cuts, cracks and deformation as well as changes in

properties from deposits or embrittlement) must be replaced. New

gaskets shall be used whenever the pump is re-assembled.

If possible, sealing elements shall be mounted without the use of

mounting aids like grease or adhesives, unless authorised

mounting aids are used.

19

Loading...

Loading...