Multitec

2.6 Safety instructions for Maintenance,

Inspection and Installation work

The operator is responsile for ensuring that all maintenance,

inspection and installation work be performed by authorised,

qualified specialist personnel who are thoroughly familiar with

the manual.

Work on the machine must be carried out only during standstill.

The shutdown procedure described in the manual for taking the

machine out of service must be adhered to without fail (See

section 6.3).

Pumps or pump units handling media injurious to health must be

decontaminated.

Immediately following completion of the work, all safety relevant

and protective devices must be re-installed and/or reactivated.

Please observe all instructions set out in the chapter on

“Commissioning” (6.1) before returning the machine to service.

2.7 Unauthorised Modification and Manufacture

of Spare Parts

Modifications or alterations of the machine are only permitted

with KSB’s prior approval. Original spare parts and accessories

authorised by KSB ensure safety. The use of other parts will

invalidate KSB’s liability for consequential damage.

2.8 Unauthorised modes of Operation

The warranty relating to the operating reliability and safety of the

pump is only valid if the machine is used in accordance with its

designated use as described by the technical data specified.

For further details please refer to the information in section 4 of

this operating manual. The limits stated in the data sheet must

not be exceeded under any circumstances.

3. Transport and Storage

3.1 Transport / Handling

Transport of the unit requires proper preparation and

handling.

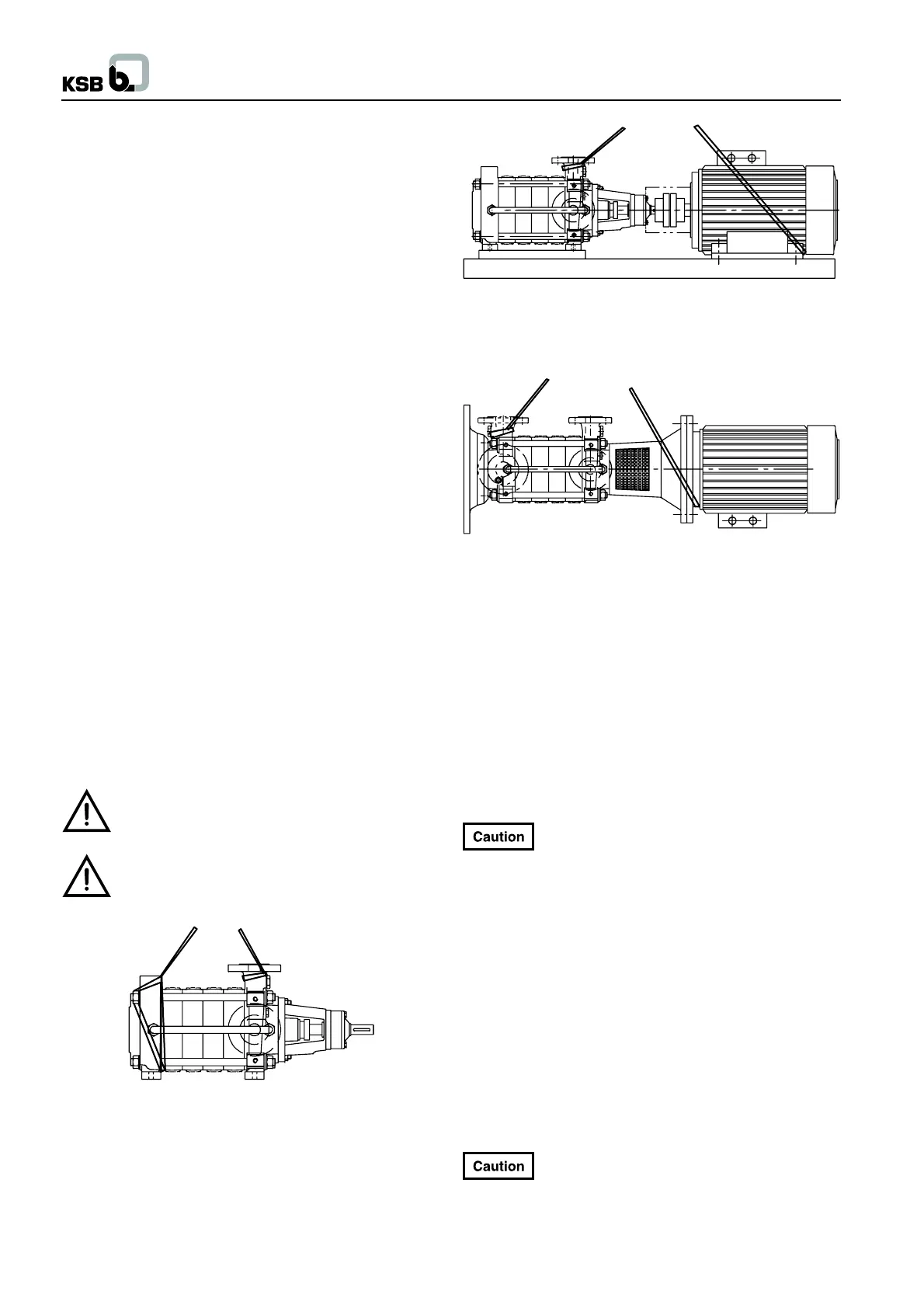

Never use the motor eyebolt for lifting the unit.

If the pump / unit slips out of the suspension

arrangement, it may cause personal injury and damage

to property.

Fig. 3.1-1 Transport of pump only

Fig. 3.1-2 Transport of the complete unit

For transporting the unit, lifting ropes shall be attached to the

pump and the motor as shown above. Never use the motor

eyebolt for lifting the unit !

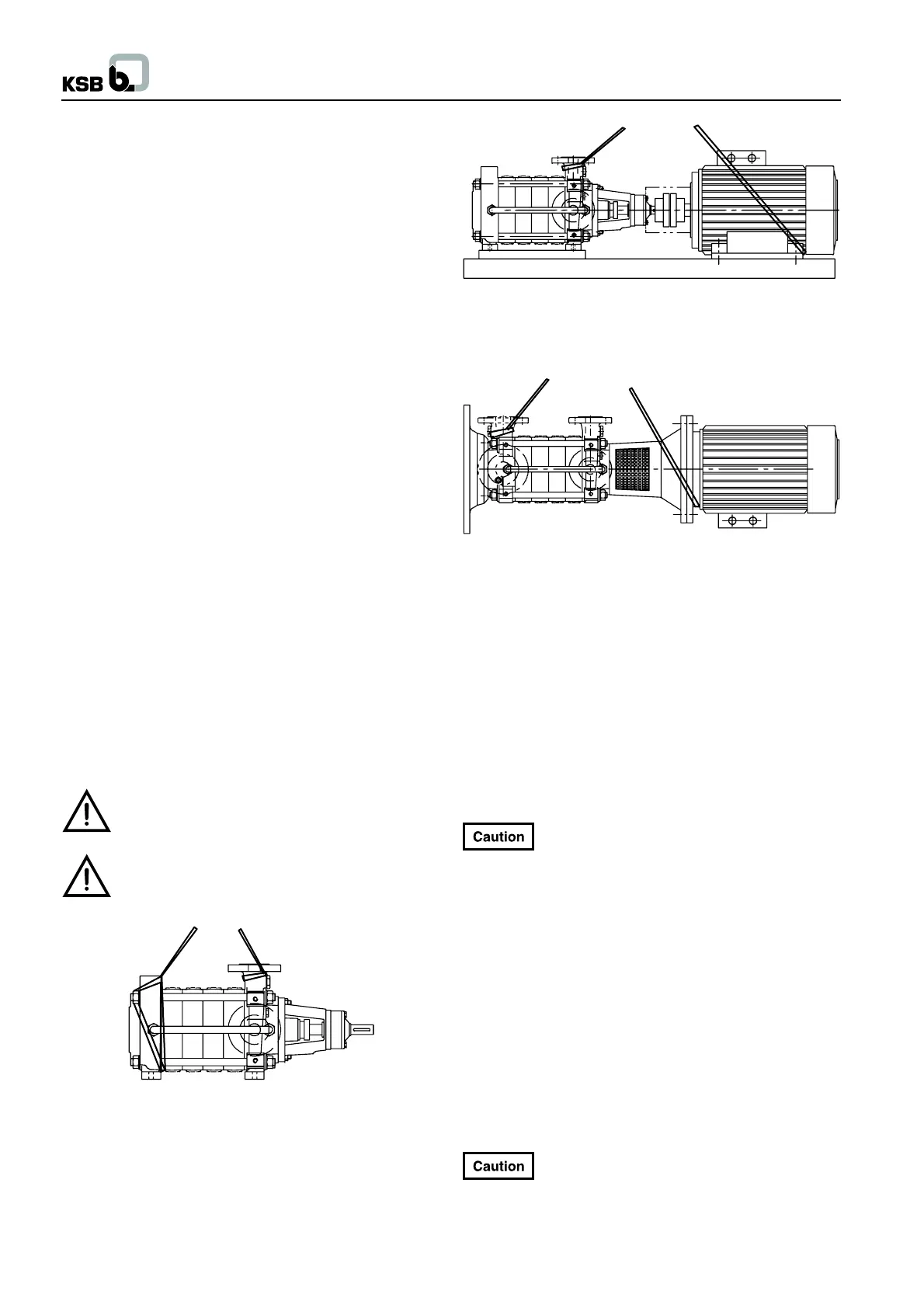

Fig. 3.1-3 Transport of close-coupled pumps and vertical

pumps

3.2 Storage / Preservation

Unless otherwise stated in the purchase order confirmation, the

pumps are supplied by our factory duly preserved for a storage

period of 3 months from delivery.

We recommend to take the following additional measures if the

pump is stored for a prolonged period of time prior to installation

:

Indoor storage of new pumps :

New pumps are preserved for indoor storage in a dry, closed

room in their original, unopened packaging for a maximum period

of 3 months.

Protect all stored goods against humidity, dirt,

vermin and unauthorised access ! All openings of

the assembled unit components are closed and must only be

opened when required during installation.

Outdoor storage with the packaging unopened :

Protect the pump / unit against humidity, dirt, vermin and

unauthorised access.

It is imperative to remove the preservative prior to normal

commissioning by flushing through the system.

If the pump is to be stored for more than 3 months :

(optional, specified in the purchase order ) :

New pump / unit

New pumps / units are specially preserved in the manufacturer’s

factory. The preservative must be removed before normal

commissioning of the pump/unit, by flushing the system

thoroughly.

The product used for this purpose is not suited for

potable water systems and, as the case may be,

must be removed completely by dismantling and subsequent

cleaning of all parts of the pump coming into contact with the

pumped medium if required. Further information in this regards

is noted in the order confirmation.

2

Loading...

Loading...