Multitec

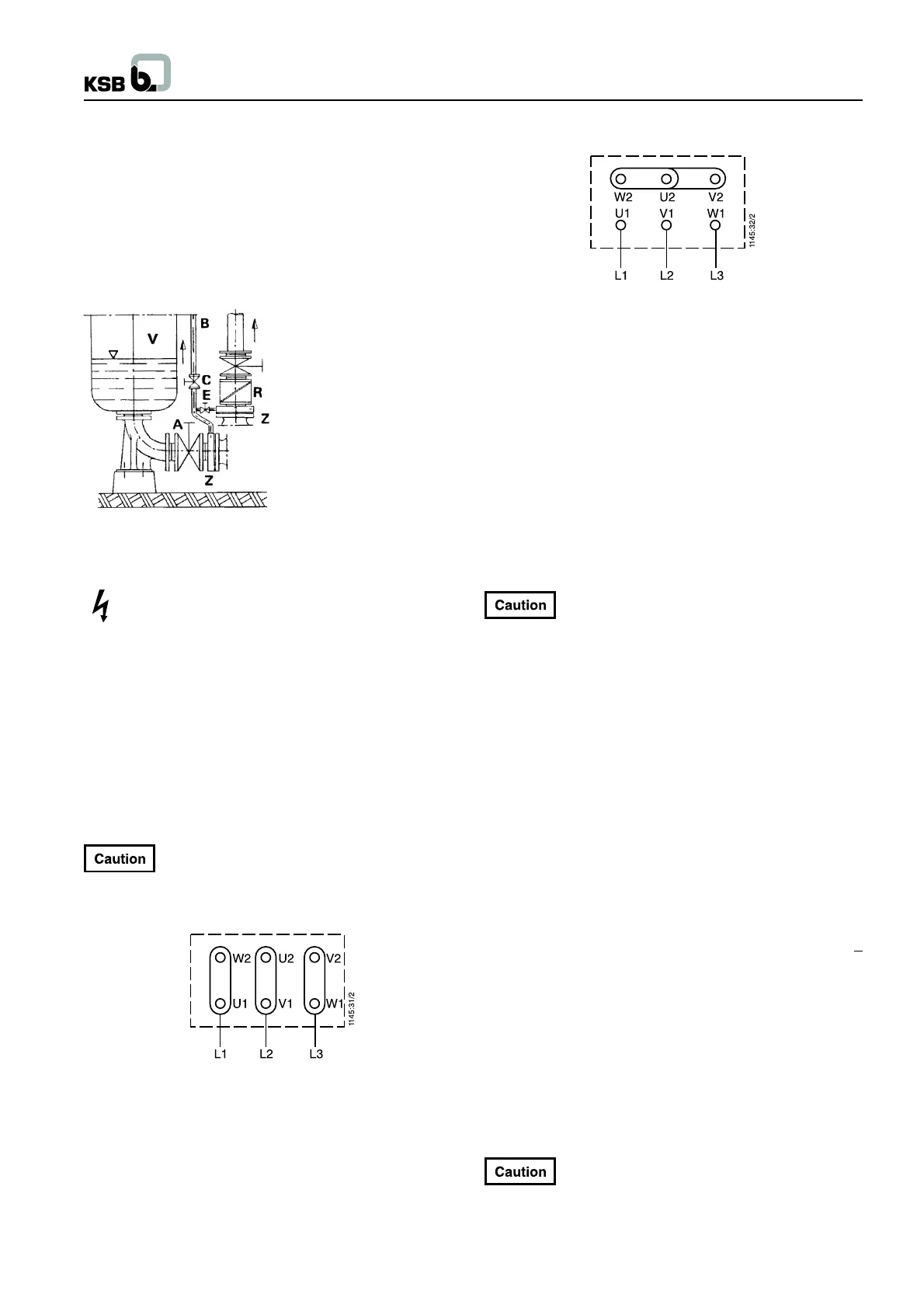

5.4.1 Vacuum Balance Line

Where liquid has to be pumped out of a vessel under vacuum, it

is advisable to install a vacuum balance line. This is should have

a nominal size of at least 25 mm and must be arranged to lead

into the vessel at a point above the highest permissible liquid

level.

An additional pipeline fitted with a shut-off valve - from the pump

discharge nozzle to the balance line - facilitates venting of the

pump before start-up.

5.5 Connection to Power supply

Connection to the power supply must be effected by a

trained electrician only (see 5.1). The applicable DIN VDE

regulations must be complied with.

Check available mains voltage against the data on the motor

rating plate and select appropriate start-up method.

Connection to the power supply must be effected in accordance

with the technical regulations of the responsible local energy

supply company.

We strongly recommend to use a motor protection switch.

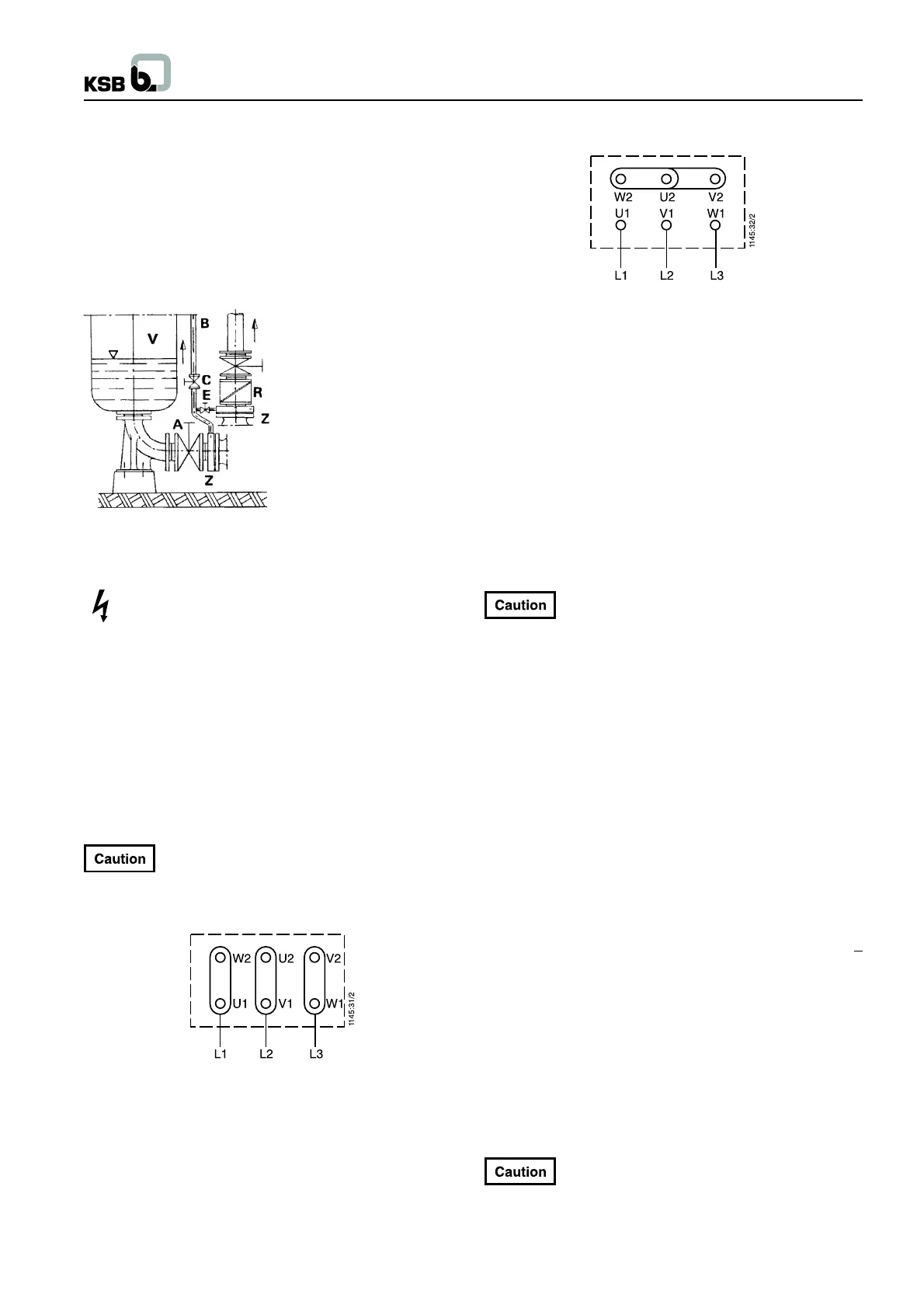

5.5.1 Connecting the Motor

Connect the motor in accordance with the circuit diagram in the

terminal box or as illustrated in Fig. 5.5-1 / Fig. 5.5-2.

Prior to starting the motor, check whether the

connection of the terminals is tight and re-tighten

possibly loose wires.

starting (low voltage)

Fig. 5.5-1 Connection diagram for three-phase motors,

starting

Y starting (high voltage)

Fig. 5.5-2 Connection diagram for three-phase motors,

Y starting

5.5.2 Setting the Time-Lag Relay

Make sure that in the case of three-phase motors with star-delta

starting method switching over from star to delta will be effected

at very short intervals. Prolonged switch-over intervals may result

in pump damage.

Time-lag relay setting recommended for star-delta starting :

3-5 seconds, depending on motor rating.

EN 50014 (Regulation DIN VDE 0170/0171 Part 1) stipulates

that explosion-proof motors, type of protection IP 54, “increased

safety” (Ex)e, thermal class T3, must always be connected via

a motor protection switch.

5.5.3 Checking the Direction of Rotation

On pumps fitted with uni-directional mechanical

seals (seal codes 62 and 63) the direction of

rotation must never be checked with the pump coupled to the

motor. If the motor and pump need not be de-coupled, make sure

that the pump has been primed before checking the direction of

rotation.

The motor’s direction of rotation must correspond to the direction

indicated by the arrow on the pump resp. motor (clockwise when

seen from the motor end; on version D anti-clockwise). This can

be verified by switching the motor on and then off again

immediately.

If the unit runs in the wrong direction of rotation, interchange two

of the three phases L1, L2 or L3 of the power supply cable in the

motor terminal box.

6. Commissioning, Start-up / Shutdown

Additional information for boiler feed pump operation.

Limit values for boiler fed water and condensate when using cast

iron pump parts : pH-value 9.0 (value aimed at 9.3) O

2

content <

0.02 ppm.

Before entry into the pump, these values must be guaranteed for

all operating conditions. The fresh water content has to amount

to max. 25%.

Water treatment shall be in accordance with the VdTÜV guidelines

for feed and boiler water in steam plants of up to 64 bar.

The penetration of air into the system must be avoided by all

means.

6.1 Commissioning

Before starting up the pump make sure that the

following requirements have been met :

- The quality of the concrete foundation is in compliance with

the applicable regulations.

A Main shut-off valve

B Vacuum balance line

C Shut-off valve

E Vacuum-tight shut-off valve

R Swing check valve

V Vessel under vacuum

Z Intermediate flange

Fig. 5.4-3 Suction line and vacuum balance line

7

Loading...

Loading...