Multitec

When tightening shaft nuts, the following has to be observed :

The shaft nuts must be tightened according to the values indicated in the table “Tightening Torques of Shaft Nuts”.

Tightening of the Shaft Nuts of the Multitec

Shaft nuts without lockwasher

Does not apply to drive side of MTC 32/50/65 with self-locking shaft nut.

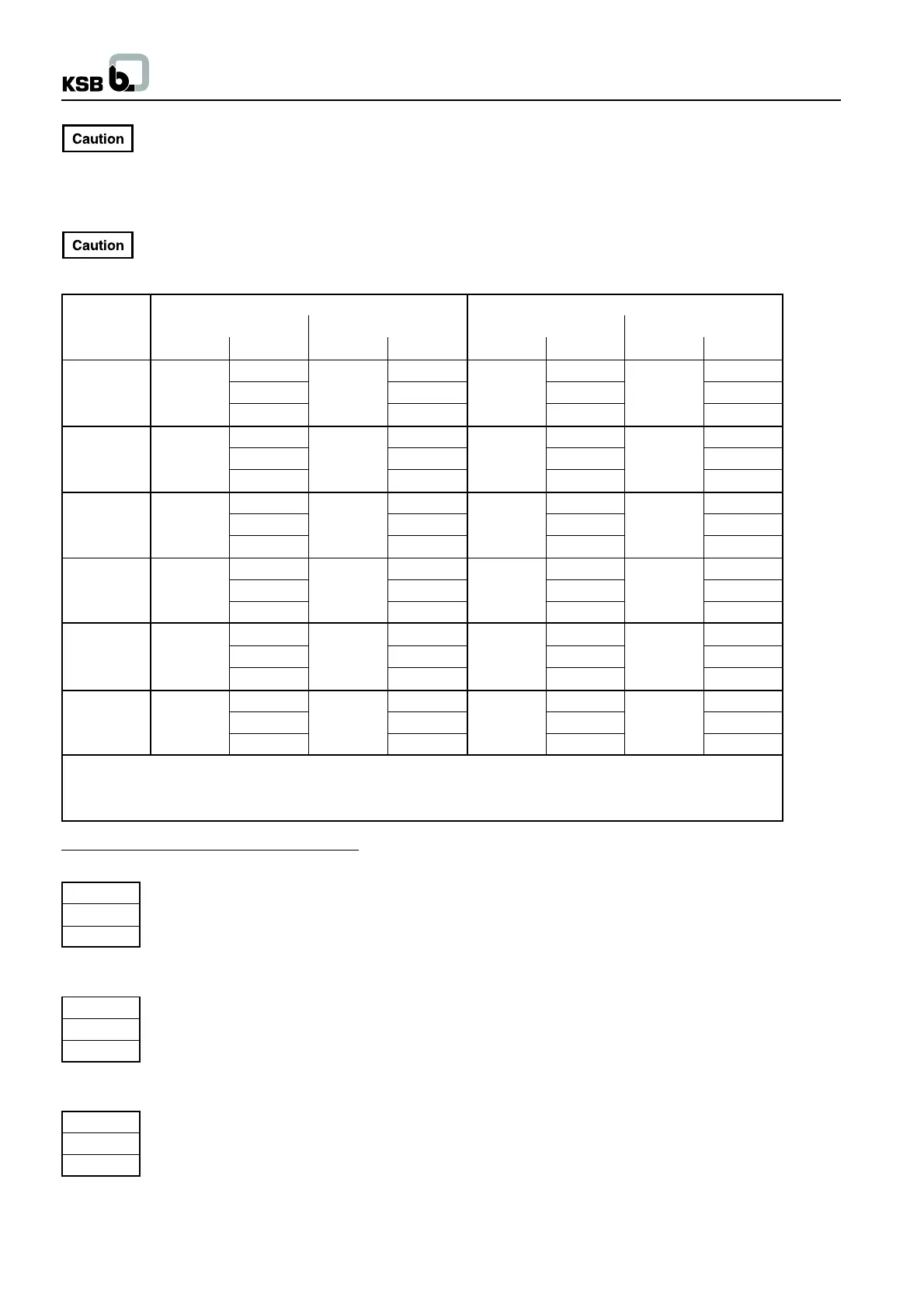

Tightening torques for shaft nuts

Drive End Non-drive End

Size A, B, C, D E, F, V A, B, E, F, V C, D

Nut Nm Nut Nm Nut Nm Nut Nm

80

1

) 80

1

) 80

1

)

MTC 32 M 25x1,5 40 (***) M25x1,5 40 (***) M 25x1,5 40 M 25x1,5 40

100 (*)

80

1

) 80

1

) 80

1

)

MTC 50 M 30x1,5 40 (***) M 25x1,5 40 (***) M 30x1,5 40 M 30x1,5 40

120 (*)

100

1

) 80

1

) 100

MTC 65 M 35x1,5 50 (***) M 30x1,5 40 (***) M 35x1,5 50 M 35x1,5 50

150 (*)

150

1

) 150

1

) 150

1

)

MTC 100

M 42x1,5

50 M 42x1,5 50 M 42x1,5 50 M 42x1,5 50

(2x)

150 (*) 150 (*) 150 (*)

200

1

) 200

1

) 200

1

)

MTC 125

M 52x1,5

60 M 52x1,5 60 M 50x1,5 60 M 52x1,5 60 (***)

(2x)

200 (*) 200 (*) 200 (*)

250

1

) 250

1

) 250

1

)

MTC 150

M 62x1,5

80

M 62x1,5

80 M 60x1,5 80

M 62x1,5

80

(2x)

250 (*)

(2x)

250 (*) 250 (*)

(2x)

250 (*)

1) loosen after first tightening

(*) block when tightening first nut

(**) self-locking nut

(***) bend over lockwasher

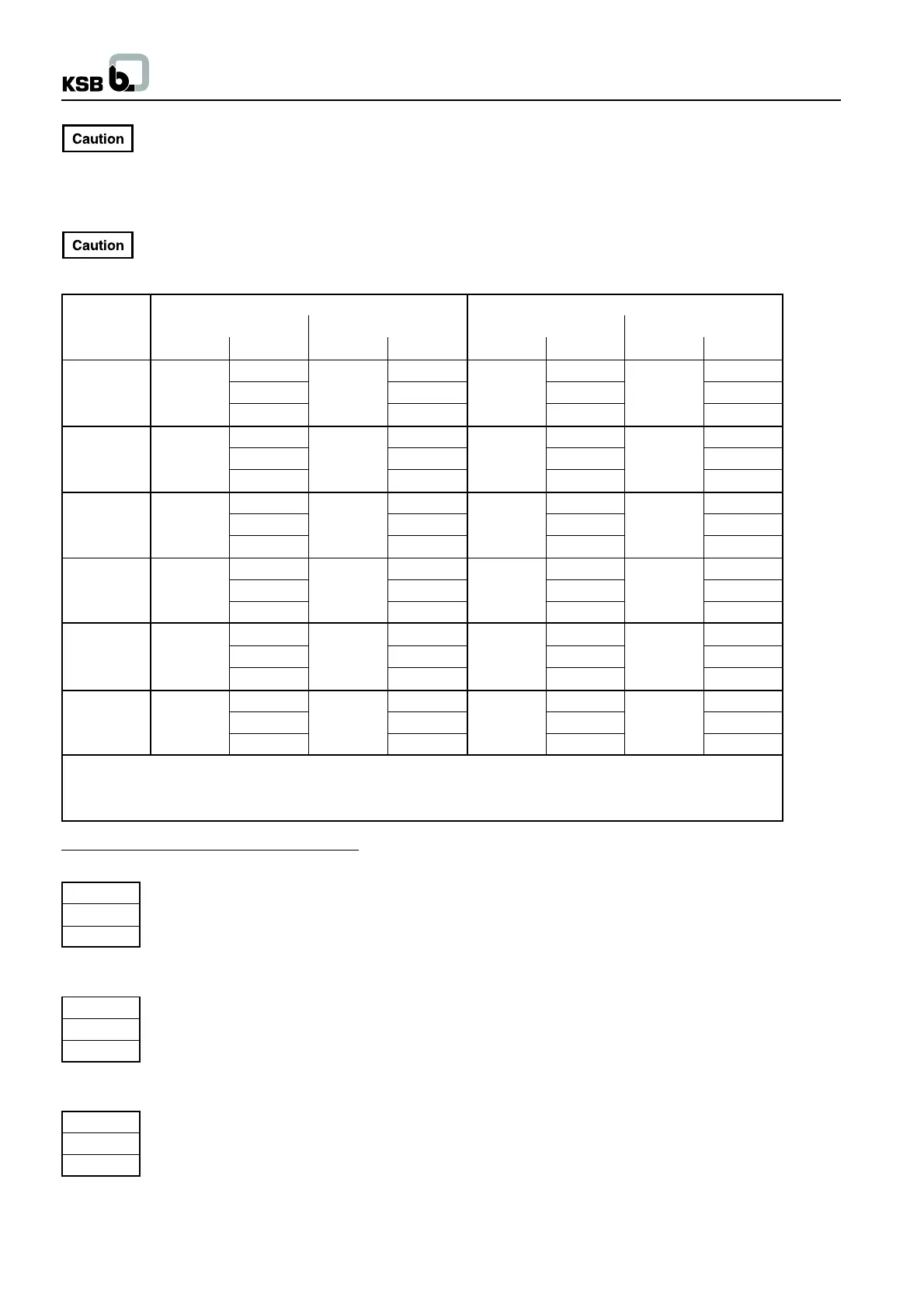

Tightening of the Shaft Nuts of the Multitec

Nut with lockwasher - (drive end and non-drive end for versions C and D)

M1 1.) Tighten nut with torque M1, then loosen again

M2 2.) Tighten with torque M2 and bend over lockwasher

Nut with counter-nut - drive end (and non-drive end for versions C and D)

M1 1.) Tighten first nut with torque M1, then loose again

M2 2.) Tighten first nut with torque M2

M3 3.) Tighten second nut with torque M3, at the same time block first nut

Nut with counter-nut - drive end (except for versions C and D)

M1 1.) Tighten first nut with torque M1

M2 2.) Tighten second nut with torque M2, at the same time block first nut

Self-locking nut - old design MTC E/F/V 32/50/65 (drive side) No torques specified.

No torques given

20

Loading...

Loading...