Multitec

If there is not suitable torque wrench available for the

tightening of the shaft nuts, proceed as follows with respect to

each design :

Self-locking nut on drive end or non-drive end

(versions C and D)

• Tighten fast the shaft nut firmly

• Loosen the shaft nut again

• Apply adhesive to thread (e.g. LOCTITE)

• Moderately tighten the shaft nut

Nut with lockwasher on drive end

(or non-drive end versions C and D)

• Tighten the shaft nut firmly

• Loosen the shaft nut again

• Moderately tighten the shaft nut

• Bend over lockwasher

Nut with counter-nut on drive end or non-drive end

(versions C and D)

• Tighten fast first shaft nut firmly

• Loosen first shaft nut again

• Moderately tighten first shaft nut

• Block first shaft nut using suitable tool and tighten counter-

nut firmly against first shaft nut

Nut with counter-nut no non-drive end

(all versions except C and D)

• Moderately tighten first shaft nut

• Block first shaft nut using suitable tool and tighten counter-

nut closely against first shaft nut

Fixed bearings

The fixed bearing is the coupling-side bearing on the coupling

end. Deep groove ball bearings are installed in size 32. The other

sizes are equipped with angular contact ball bearings mounted

in X arrangement (see sectional drawing). The spacer discs 551.1

serve to position the rotor in axial direction.

Axial adjustment of the rotor in not required.

The correct axial position of the rotor is achieved by putting in

the bearing housing 350.1 spacer discs 551.1 to a total thickness

of 1.6 mm (1 x 1 mm + 3 x 0.2 mm) on the side of the bearing (or

angular contact ball bearings).

On previous versions, the axial alignment of the

rotor is set by putting on both sides of the bearing

(or the angular contact ball bearing) spacer discs 551.1 to a total

thickness of 1.6 mm.

The tightening of the cover bolts 901.1 (or 901.8 for oil-lubricated

bearings) must be done in diagonally opposite sequence taking

into consideration the tightening torques as follows :

MTC 32/50/65 30 Nm

MTC 100/125/150 40 Nm

After installation of the bearings, the following controls need to

be made :

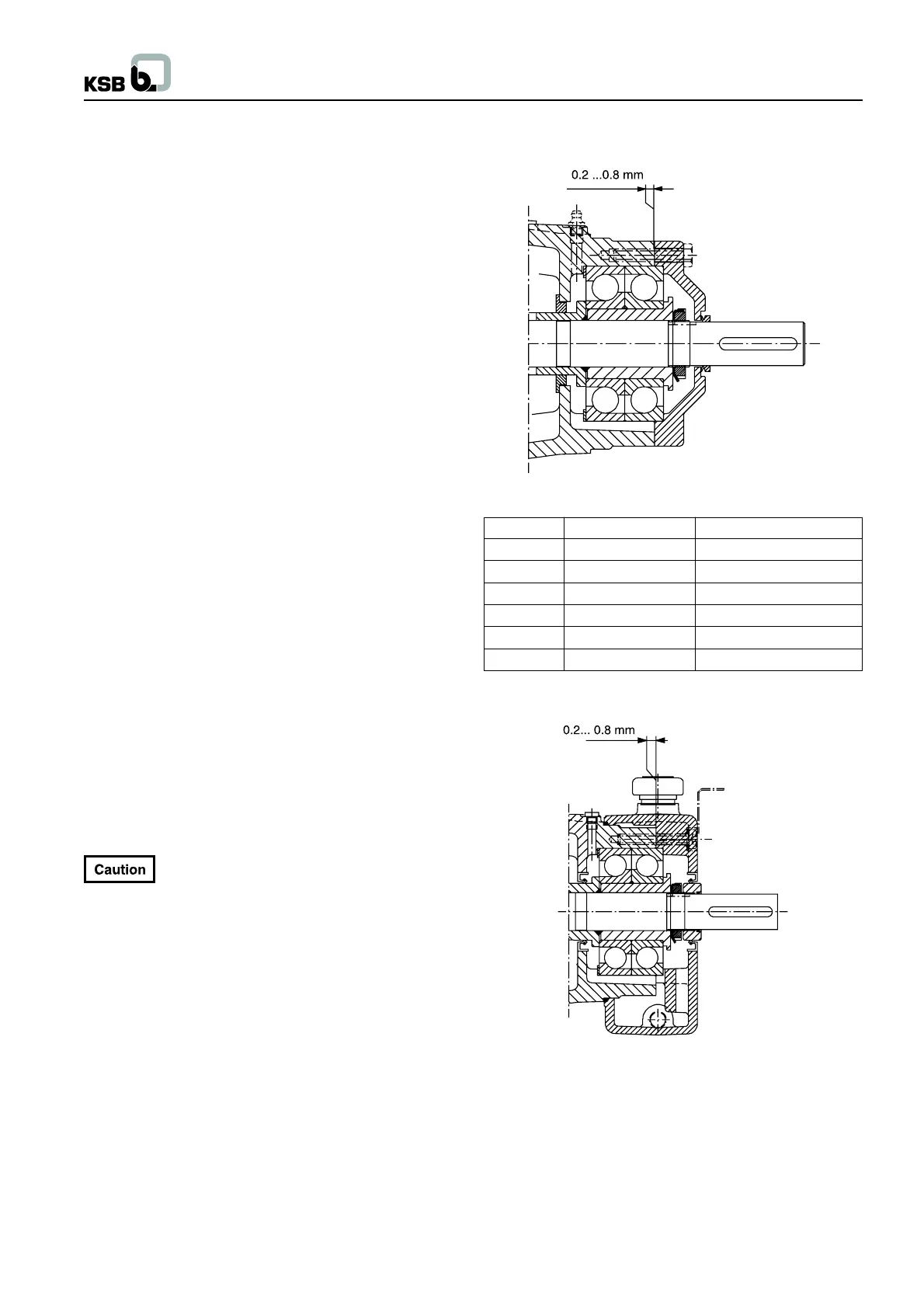

- Grease lubricated bearings : Check the clearance between

cover 360.1 and bearing housing 350.1 after having tightened

the bolts 901.1. There should be a clearance between 0.2

mm and 0.8 mm. The cover 360.1 must not rest on the bearing

housing 350.1.

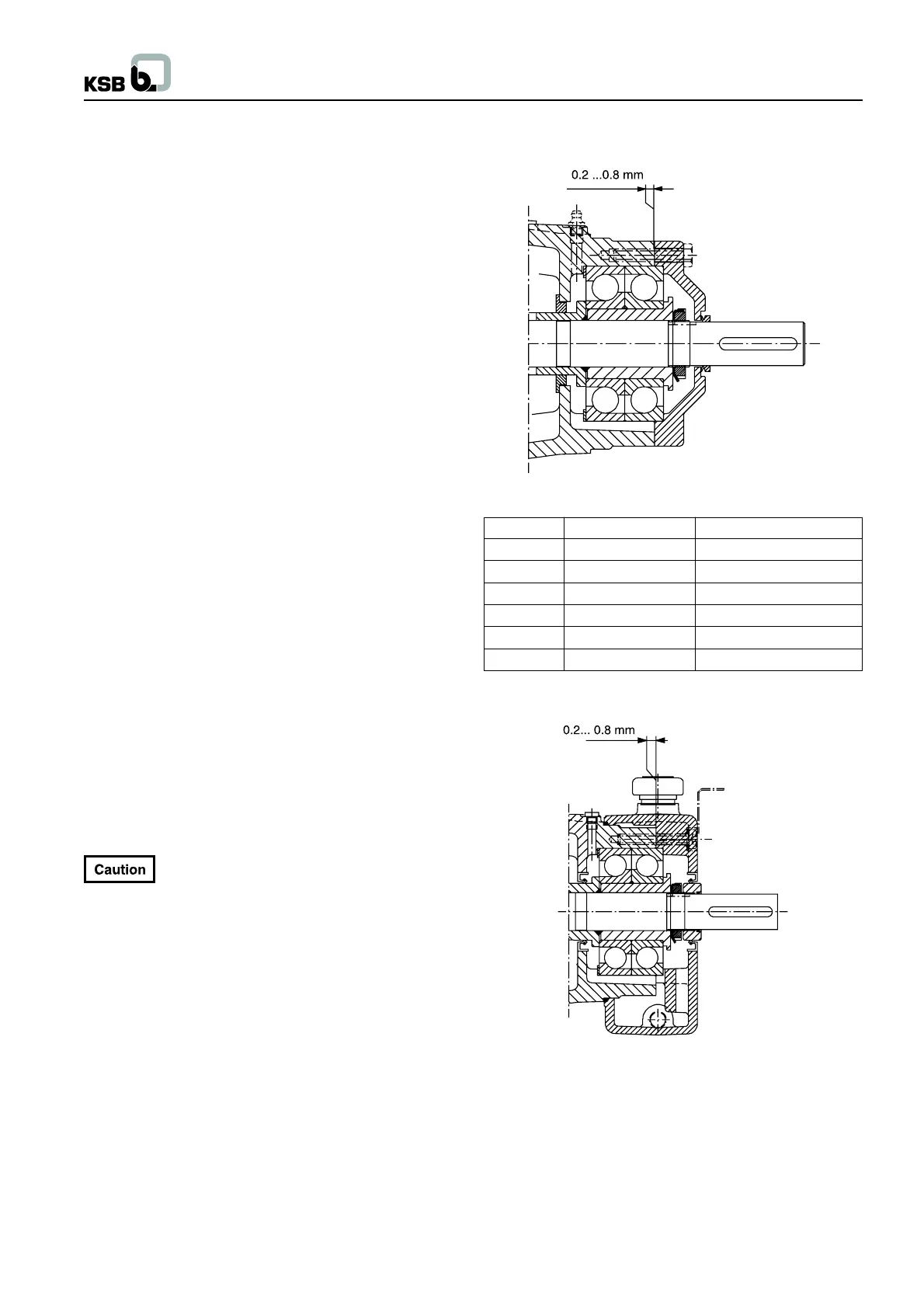

- Oil lubricated bearings : Check the clearance between cover

360.2 and bearing housing 350.1 by verifying the dimensions

prior to re-assembly (if bearings or cover have to be replaced).

Rolling element bearings

Grease lubricated bearings

Fig. 7.4-4

Pump size Drive end 320.1 Non-drive end 320.2

32 6309 ZZ C3-HT 6309 ZZ C3-HT

50 2 x 7309 BUA 6309 ZZ C3-HT

65 2 x 7309 BUA 6309 ZZ C3-HT

100 2 x 7312 BUA 6312 C3

125 2 x 7312 BUA 6312 C3

150 2 x 7315 BUA 6315 C3

Oil-lubricated bearings

Fig. 7.4-5

The same rolling element bearings will be installed for oil lubrication

as for grease lubrication.

Exception : Instead of bearing design 6309 ZZ C3-HAT, rolling

element bearing type 6309C will be used for oil lubrication.

21

Loading...

Loading...