Multitec

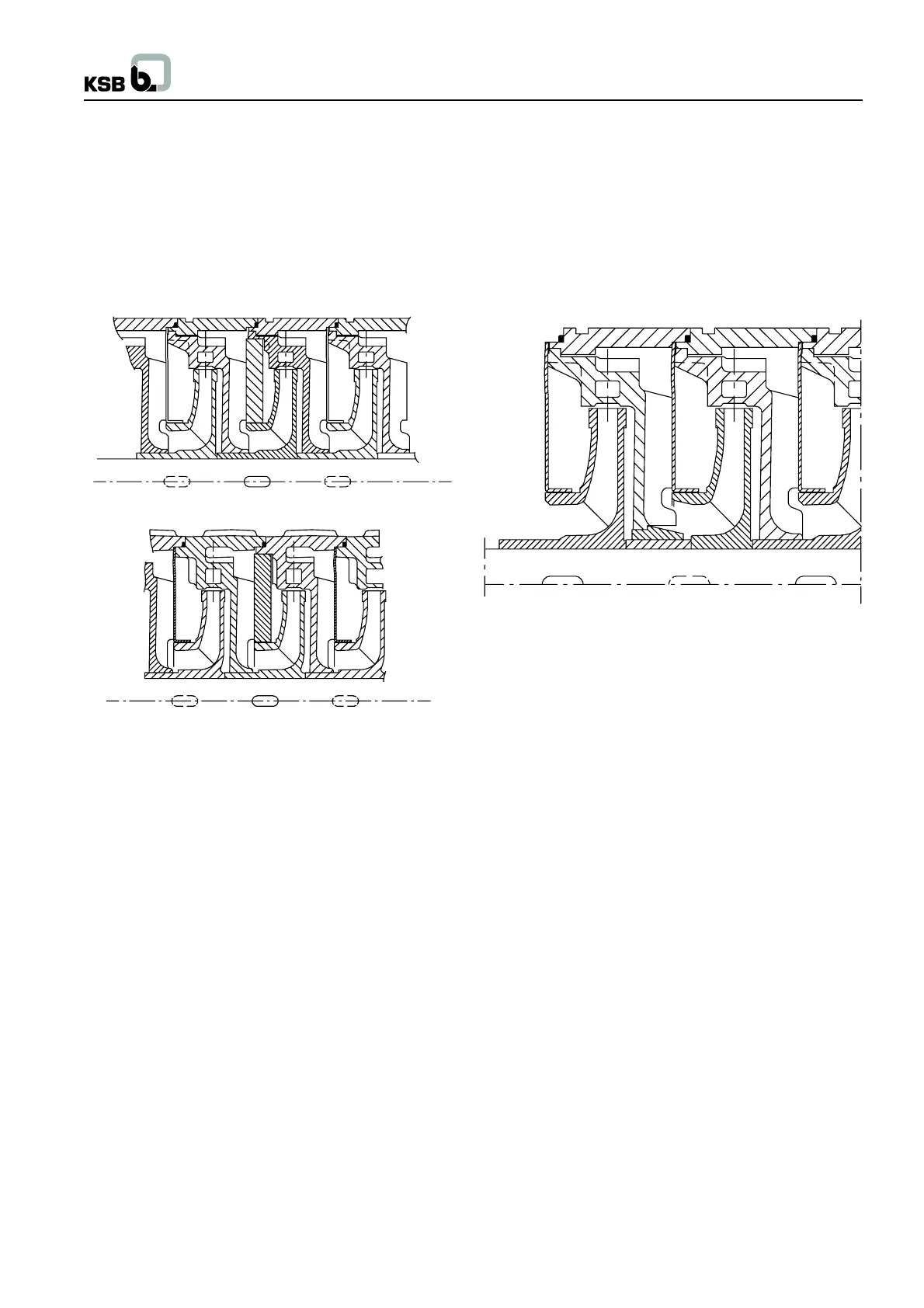

N.B.: The advantage of the deep-drawn discs is their hardness

at the sealing gap due the forming procedure during production.

Deep-drawn parts are much harder than machined parts, which

places the deep-drawn components at a considerable advantage

in the event of the impeller coming into rubbing contact during

pump operation. This feature is of particular importance for pumps

with stainless steel impellers.

Should repair method c) be applied, the clearance gaps have to

be increase by approx. 0.1 mm as against the original clearance

gaps.

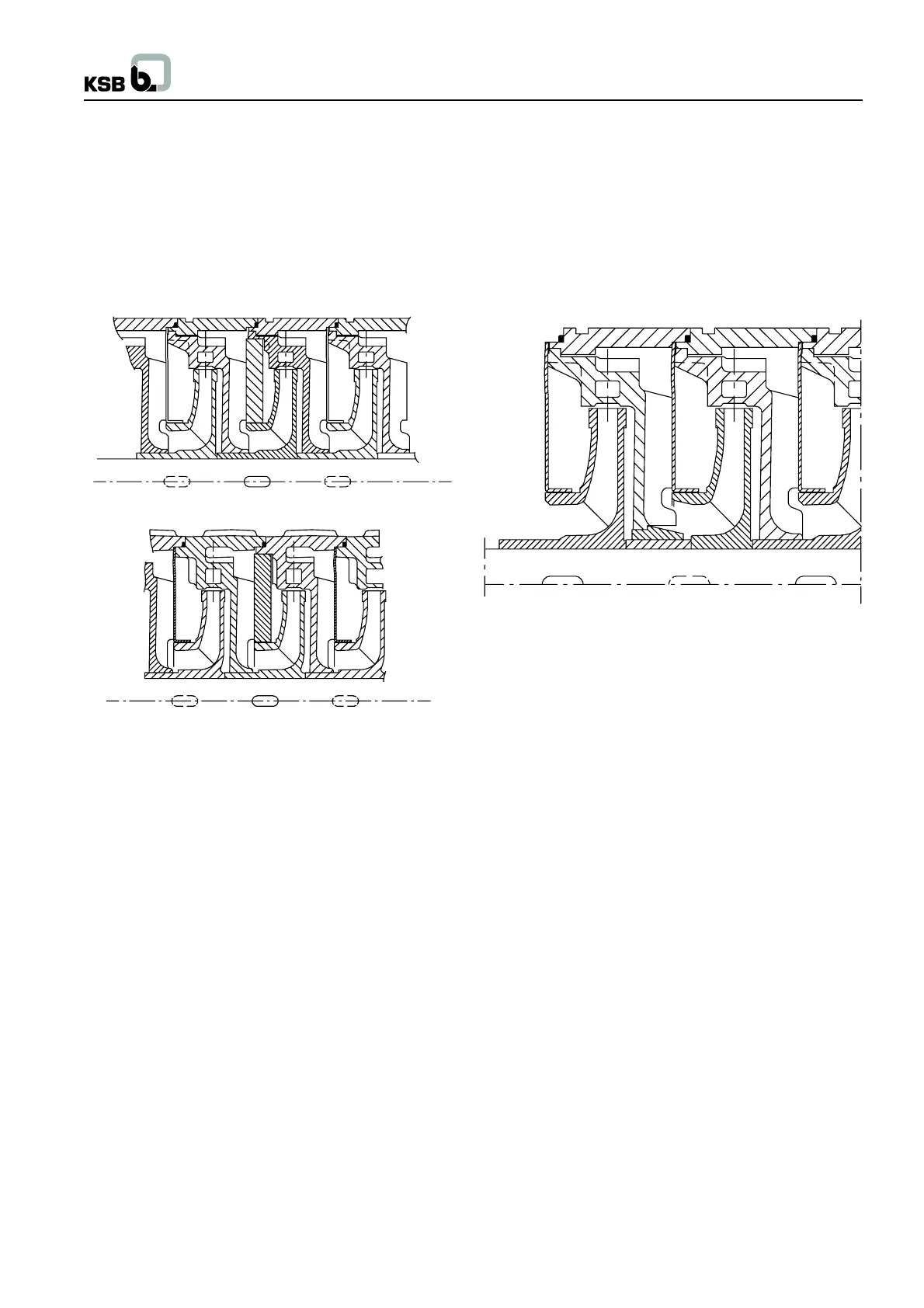

Fig. 7.5-3

Installation and Re-commissioning

Please refer to the appropriate sections of these operating

instructions.

Clearance gaps between impeller 230 and diffuser :

a) Re-working the impellers at the sealing gaps of the hubs.

Re-working the diffusers and installing a casing wear ring to

ZN 140.

b) Should hub thickness be insufficient after re-working, replace

the impeller or install a spacer sleeve (see drawing below).

The spacer sleeve must be driven by the impeller key.

Attention should be given that the carrying key length in the

impeller is at least 2/3 of the total (carrying) key length.

Fig. 7.5-1

Fig. 7.5-2

23

Loading...

Loading...