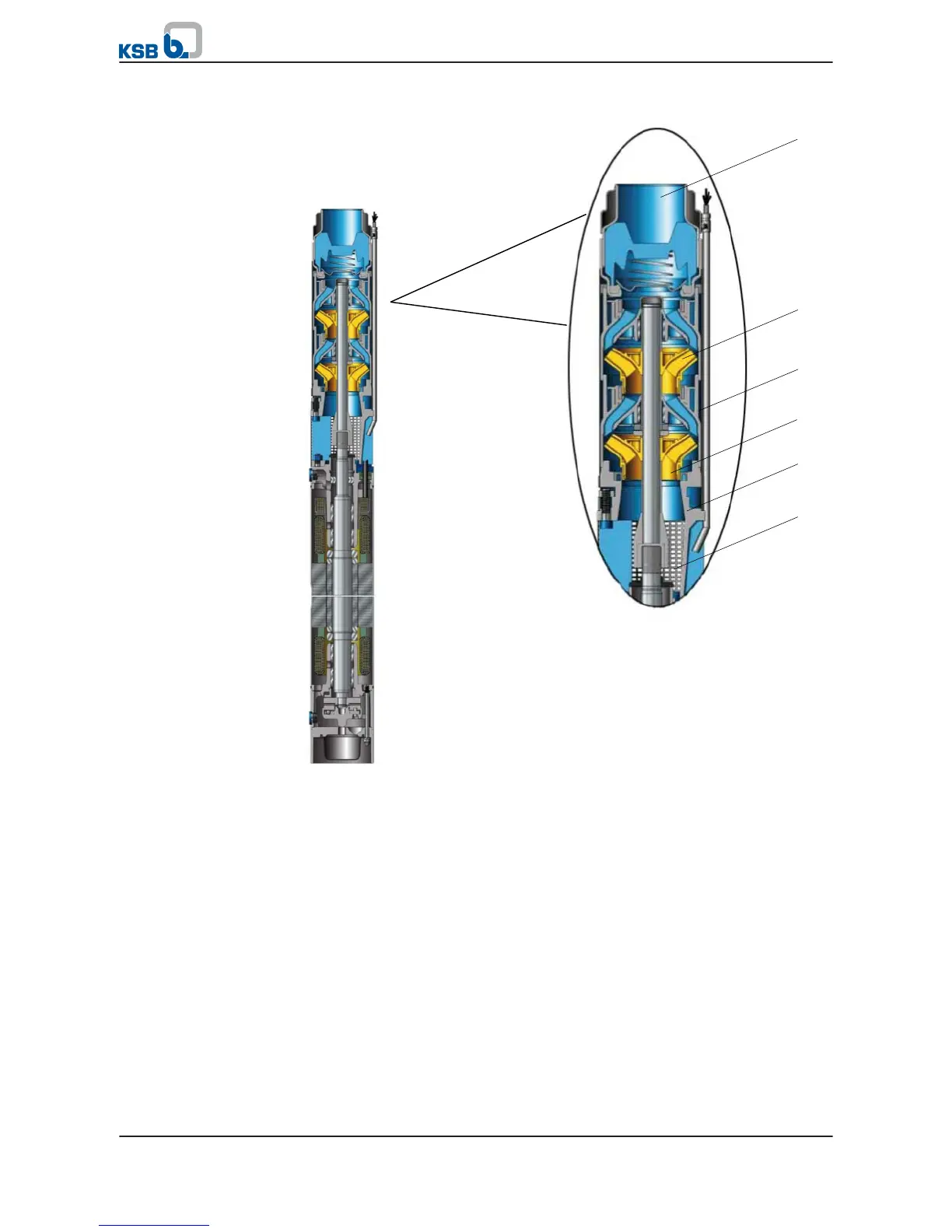

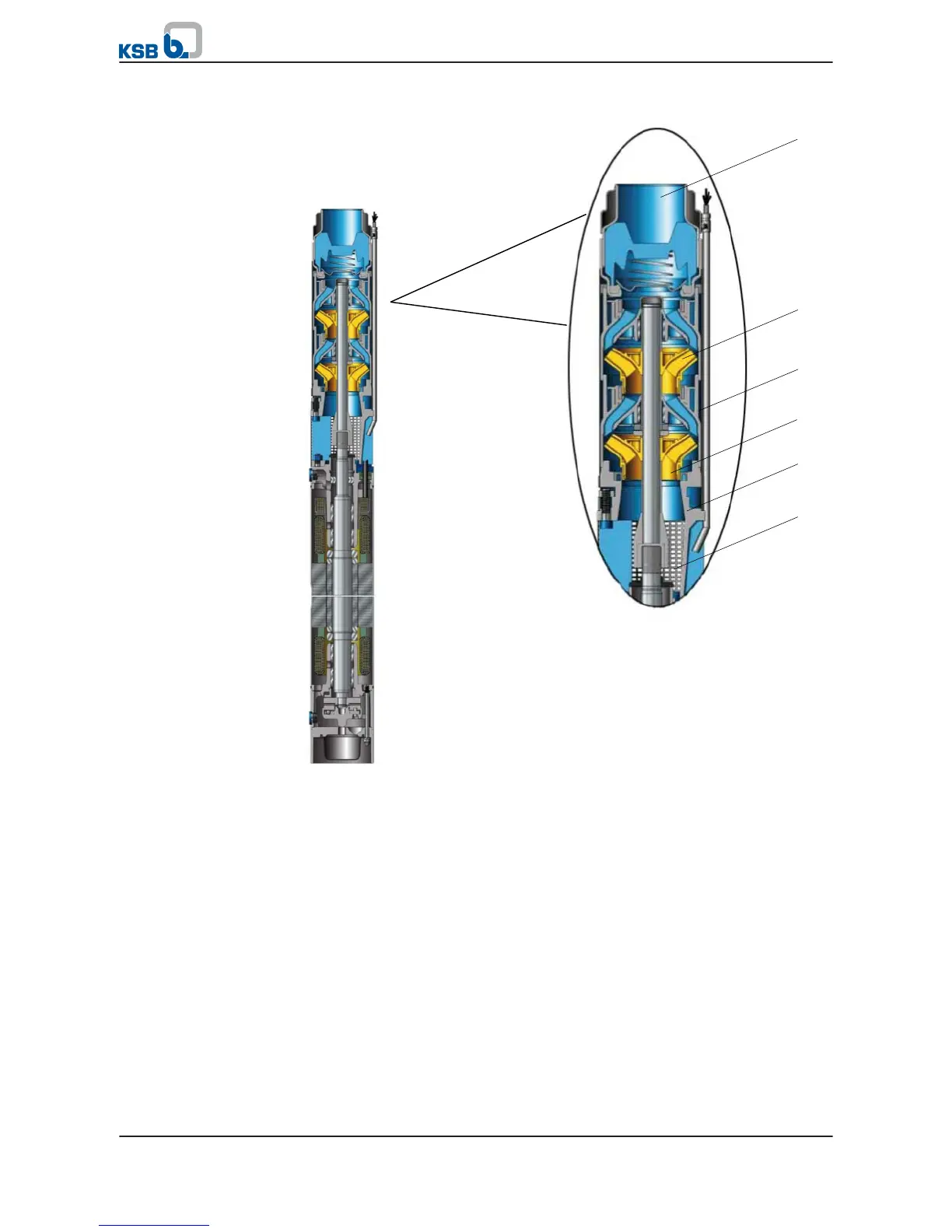

Fig. 3: Sectional drawing, example of a UPA

Pump and motor are connected by a rigid coupling. The stage casings are supported

by straps or stud bolts. A suction strainer at the suction casing protects the pump

from coarse particles in the fluid. The pump set is connected to the piping via a non-

return valve or connection branch with either internal thread or flanged end

(optional).

The fluid flows along the motor and enters the suction casing (2) through the suction

strainer (1). It is accelerated outward by the suction impeller (3). In the flow passage

of the stage casing (4) the kinetic energy of the fluid is converted into pressure

energy, and the fluid is routed to the next impeller (5). This process is repeated in all

stages until the fluid has passed the last impeller (5). It is then guided through the

integrated non-return valve to the connection branch (7), where it leaves the pump.

The integrated non-return valve prevents uncontrolled backflow of the fluid.

4.6 Scope of supply

Depending on the model, the following items are included in the scope of supply:

▪

Pump set with motor lead

Optional: pump and/or motor as individual units

Design

Function

4 Description of the Pump (Set)

18 of 64

UPA, UPZ, BSX

Loading...

Loading...