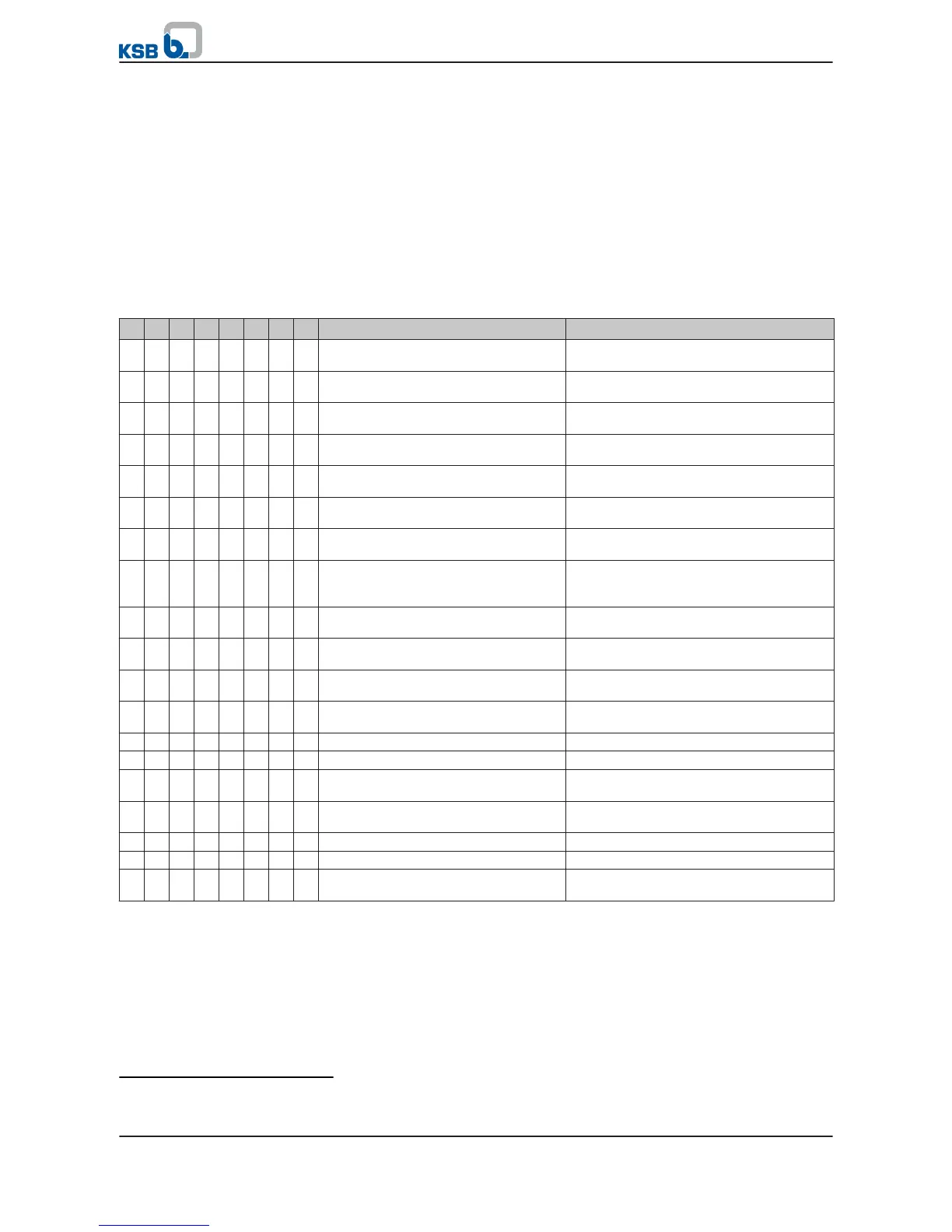

8 Trouble-shooting

Pump is running but does not deliver

Pump delivers insufficient flow rate

Insufficient discharge head

Vibrations and noise during pump operation

Unit tripped by overcurrent relay

Fuses have blown

Pump set cannot be started up

Pump set cannot be switched off

Table 21: Trouble-shooting

A B C D E F G H Cause

Remedy

17)

✘

Pump delivers against an excessively

high discharge pressure.

Open the shut-off valve to re-adjust to

duty point.

✘

Pump delivers against an excessively

low discharge pressure.

Close the shut-off valve to re-adjust to

duty point.

✘ ✘

Deposits in the impellers Remove deposits.

Contact KSB.

✘ ✘

Wrong direction of rotation (in case of

3 ~)

Interchange two of the phases of the

power supply cable.

✘ ✘

Wear of internal components Replace worn parts by new ones.

Contact KSB.

✘

✘

Motor is running on two phases only. Replace defective fuse.

Check cable connections.

✘

✘

No power supply Check electrical installation,

contact electric utility company.

✘

✘

Pump clogged by sand Clean suction casing, impellers, stage

casings and check valve.

Contact KSB.

✘

✘ ✘ ✘

Motor winding or electric cable are

defective.

Contact KSB.

✘ ✘ ✘

Defective or clogged riser (pipe and

sealing elements).

Replace affected pipes.

Replace sealing elements.

✘

Water level lowered too much during

operation.

Contact KSB.

✘

✘ ✘

Impermissible air or gas content in the

fluid handled

Contact KSB.

✘

Mechanical defect on pump or motor Contact KSB.

✘

System-induced vibrations Contact KSB.

✘

✘

NPSH available (positive suction head)

is too low.

Submerge pump deeper.

✘ ✘

Speed is too low. Check voltage and increase, if necessary.

Contact KSB.

✘

Wrong fuse size Fit correct fuse size.

✘

✘ ✘ Defective overcurrent relay Check and replace, if necessary.

✘

Motor winding not suitable for

operating voltage available

Replace the pump set.

Contact KSB.

A

B

C

D

E

F

G

H

17)

Pump set pressure must be released before attempting to remedy faults on parts which are subjected to pressure.

8 Trouble-shooting

UPA, UPZ, BSX

53 of 64

Loading...

Loading...