1. If already assembled, remove the suction strainer and cable guard from the

pump.

2.

Clean all locating surfaces, contact surfaces and threads with a cleaning agent.

Thoroughly remove any residues of the preservative.

3. Grease the shaft stub of the motor and the sleeve coupling of the pump.

4. Apply a thin layer of grease to the locating surfaces and contact surfaces.

5. On new motors, remove the transport lock from the shaft.

To do so, remove screw (1) and strap (2).

6. Position the motor horizontally and secure it against tipping over.

7.

Suspend the pump from the crane and align it so that the cable recess, coupling

sleeve and screws/bolts are in the correct position.

8. Centre the pump, fit the sleeve coupling around the shaft stub, and lower the

pump.

9. Fit nuts and assembly studs. Apply Loctite 242 and tighten the nuts by hand.

10. Insert the grub screw into the coupling sleeve and secure it with the

corresponding securing pin/bolt, if any, to prevent the pump from lifting off the

motor. Insert the securing screw into the coupling sleeve. Apply Loctite 242.

Gently screw in the screw until flush, then turn it back by

1

/

8

of a turn.

NOTE

Make sure the fitted grub screw does not touch the rotor.

11. Use a torque wrench to tighten the assembly studs; alternate sides after each

stud. Observe the tightening torque!(⇨ Section 7.6.2 Page 51)

12.

Re-check the tightening torques!

13. Fasten the power cables to the pump set together with the suction strainer and

the cable guard.

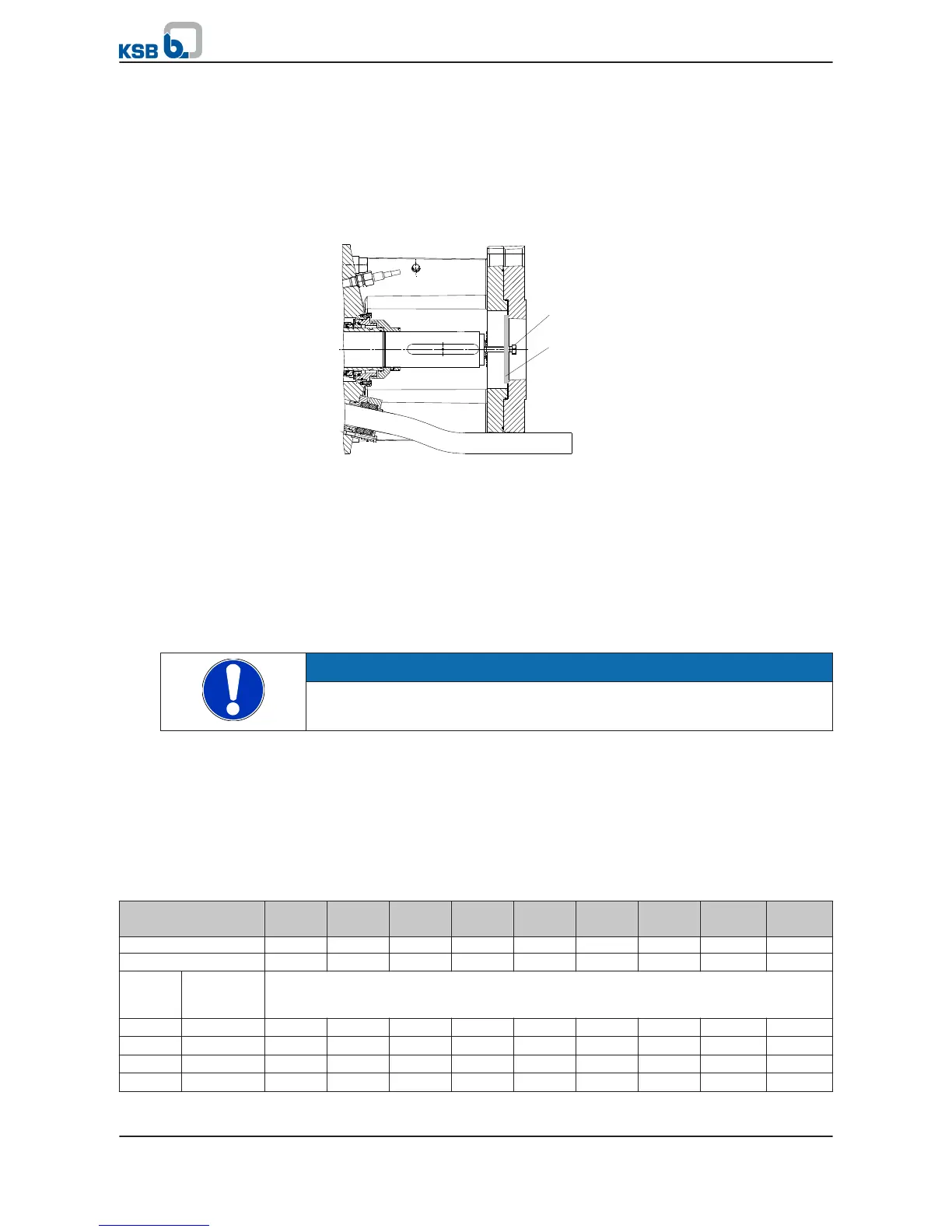

7.6.2 Tightening torques

Table 20: Maximum permissible tightening torques for the screws/bolts

Material/Property

class

5.6 8.8 C3 - 80 A4 - 50 A4 - 70 A4 - 80 1.4462 CuAl10Ni CuNi1,5S

i

Rp 0.2 [N/mm²] 300 640 640 210 450 600 450 270 540

Metric thread

Coarse-

pitch

thread

Fine-pitch

thread

Tightening torque M

A

[Nm]

M4

1.45 3.1 3.1 1.0 2.15 2.9 2.15 -- 2.6

M5

2.85 6.1 6.1 2.0 4.25 5.7 4.25 -- 5.1

M6

4.9 10.4 10.4 3.4 7.3 9.75 7.3 -- 8.75

M8

11.8 25.2 25.2 8.3 17.7 23.7 17.7 -- 21.3

7 Servicing/Maintenance

UPA, UPZ, BSX

51 of 64

Loading...

Loading...