2RV/2RW/2RX/2RY/3RA-3

7-38

J0501/J0502/J0503: Cassette no feed

Condition: Mark of paper feed slippage at the paper leading edge (the pickup roller

cannot convey paper.)

When feeding from cassette 1-3, paper stops at the pickup roller and the next sensor does not turn on after

the feed clutch or PF feed clutch turns on.

J0501/J0502/J0503: Cassette no feed

Condition: A part other than the center part of the leading edge of the paper is

broken. (Paper jam occurs as paper is caught up before entering the retard roller)

When feeding from cassette 1-3, paper stops at the feed roller and the next sensor does not turn on after the

feed clutch or PF feed clutch turns on.

J0501/J0502/J0503: Cassette no feed

Condition: The center part of the paper leading edge is folded or torn (It does not

reach to the retard roller or retard roller does not rotate).

When feeding from cassette 1-3, paper stops at the retard roller and the next sensor does not turn on after the

feed clutch or PF feed clutch turns on.

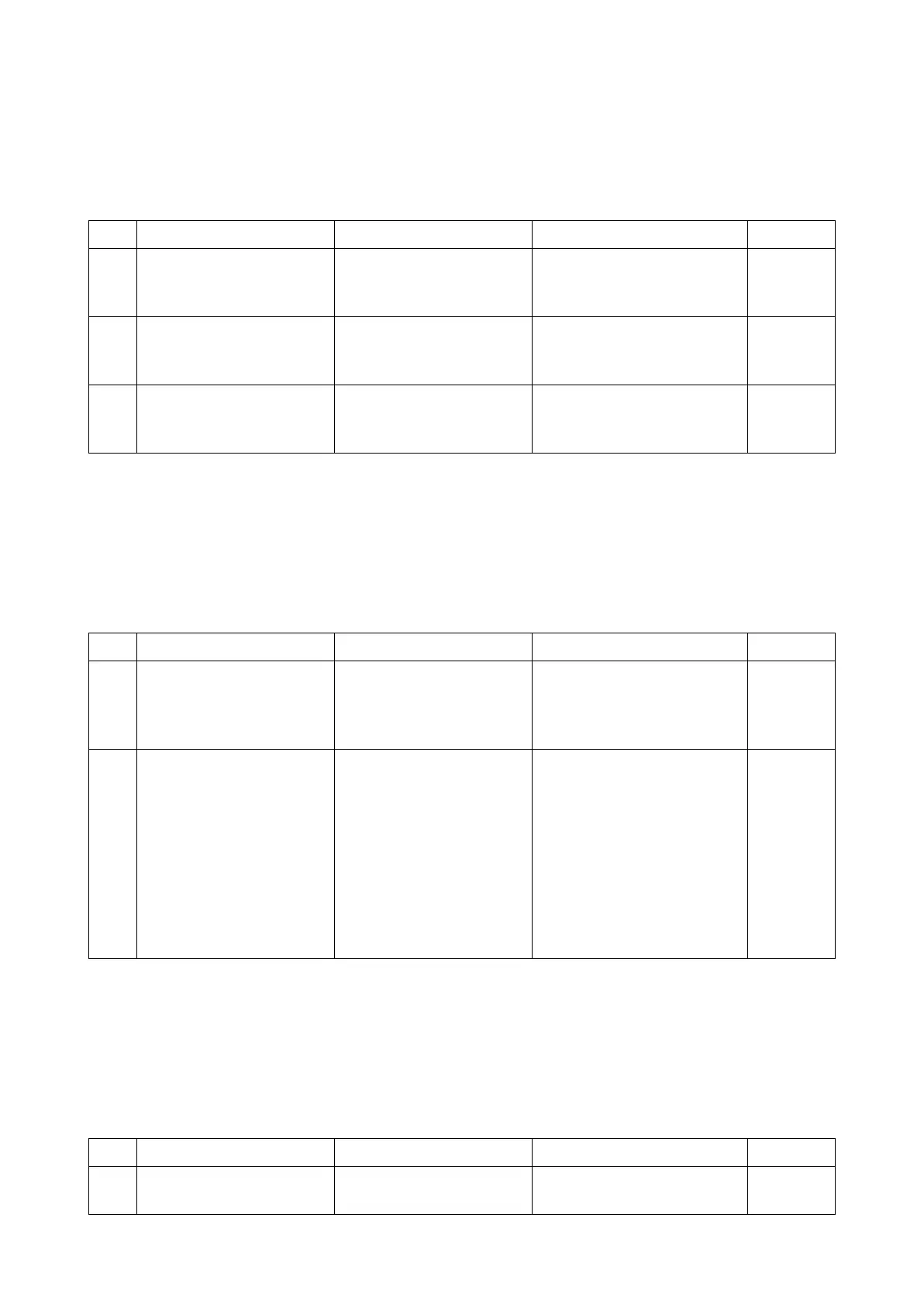

Step Check description Assumed cause Measures Reference

1 Relocating the paper width

guides

The locations of the paper

width guides do not fit with

the paper size.

Relocate the paper width

guides to fit them with the

paper size.

2 Checking the pickup roller The conveying function of

the pickup roller is not

enough.

Clean the pickup roller sur-

face. If worn down, replace it.

3 Checking the paper feed

roller

The conveying function of

the paper feed roller is not

enough.

Clean the feed roller surface.

If worn down, replace it.

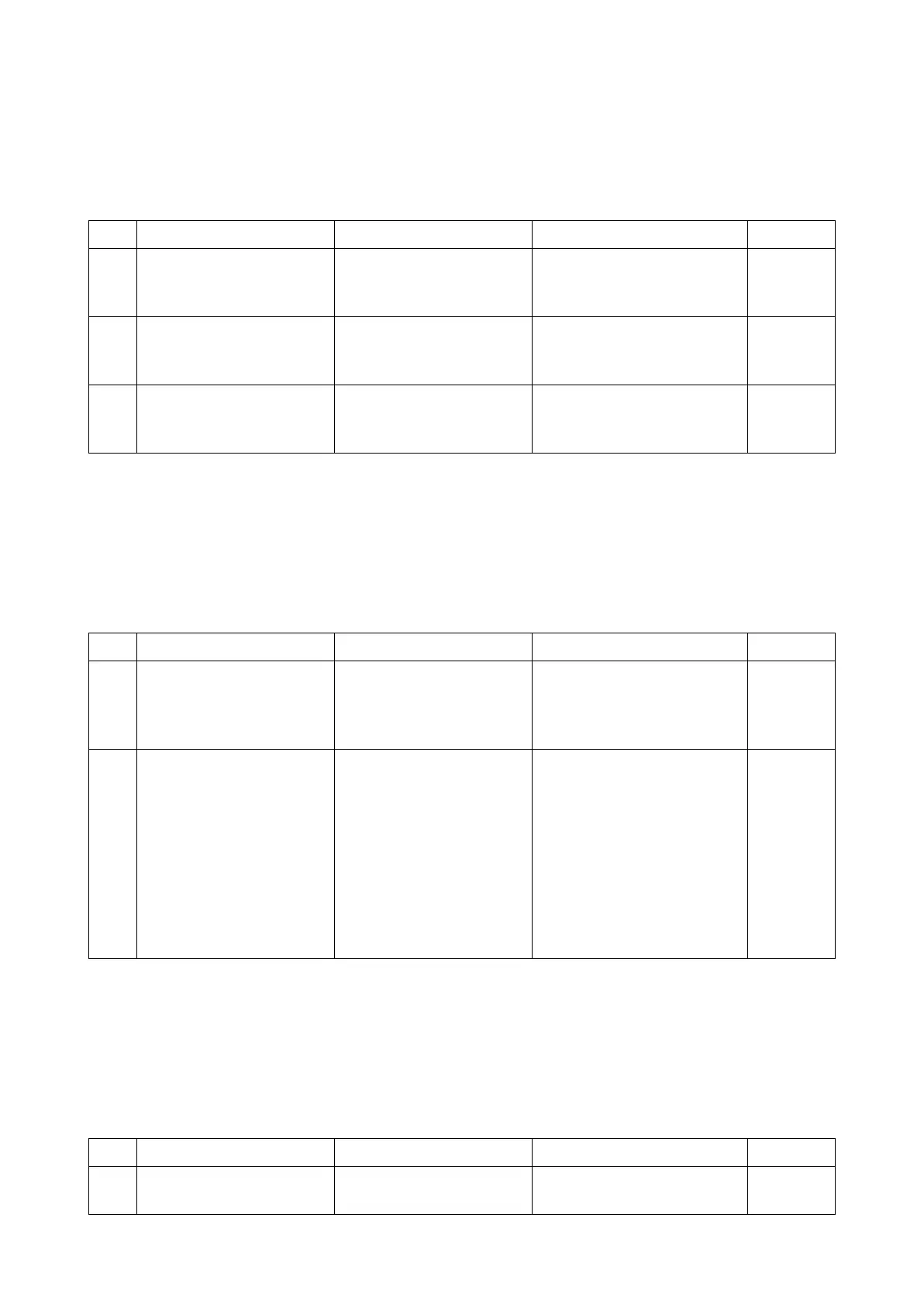

Step Check description Assumed cause Measures Reference

1 Checking the paper Paper curls downward. Correct or replace paper. If

difficult to replace, re-load

paper by switching top and

bottom ends or turning it over.

2 (In case paper is bent or

conveyed in skew) Check-

ing the conveying path

Paper is caught up by the

conveying guide or paper

piece.

If there is a paper piece or

foreign object on the convey-

ing side or a burr on the con-

veying side of the conveying

guide or on the parts such as

actuator, remove it or replace

it. If there is a scratch, defor-

mation or floating on the

sheet or film, correct or

replace it.

Step Check description Assumed cause Measures Reference

1 Checking the retard roller The retard roller convey-

ing force is not enough.

Clean the retard roller sur-

face. If worn down, replace it.

Loading...

Loading...