The FT Series Floor Standing, Combination Boiler

Page 49

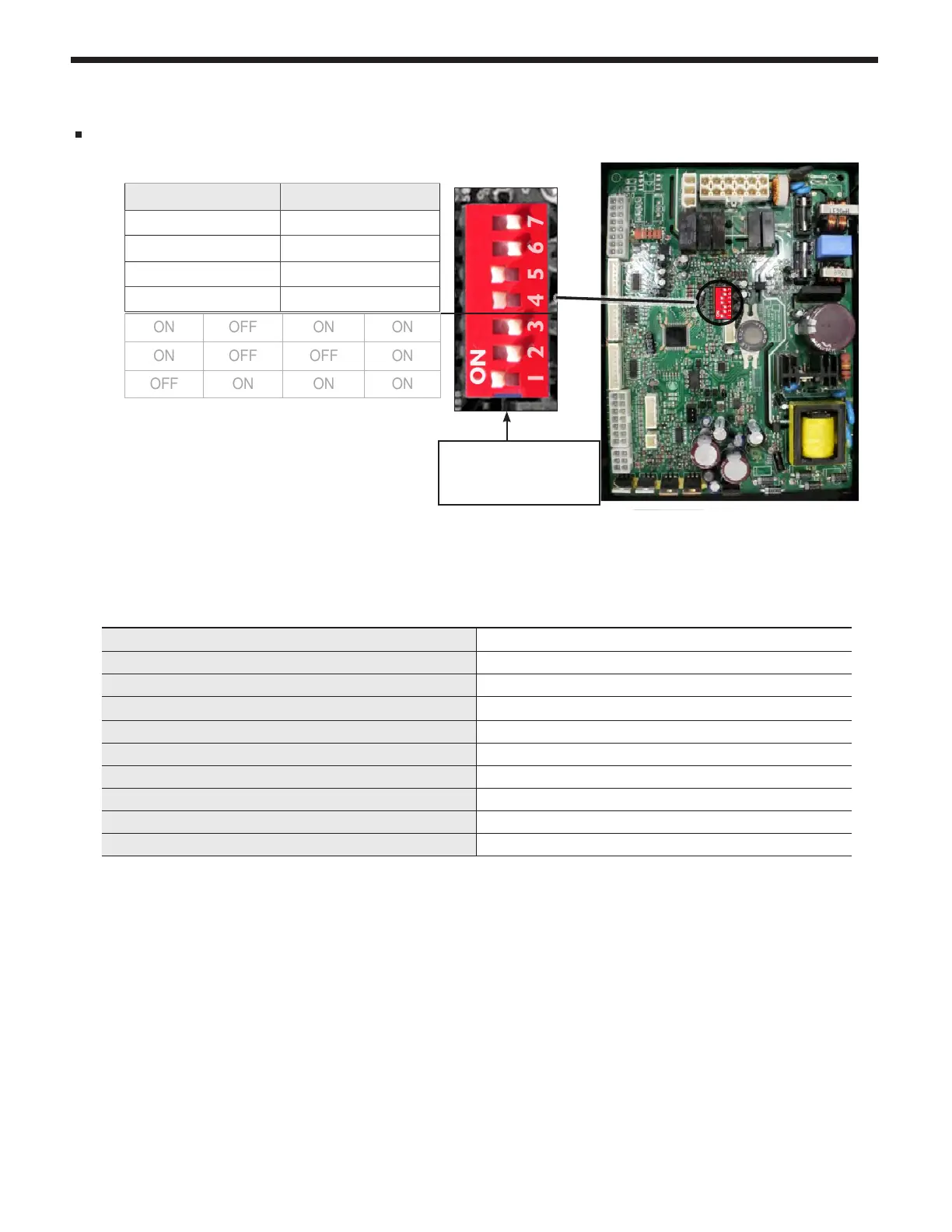

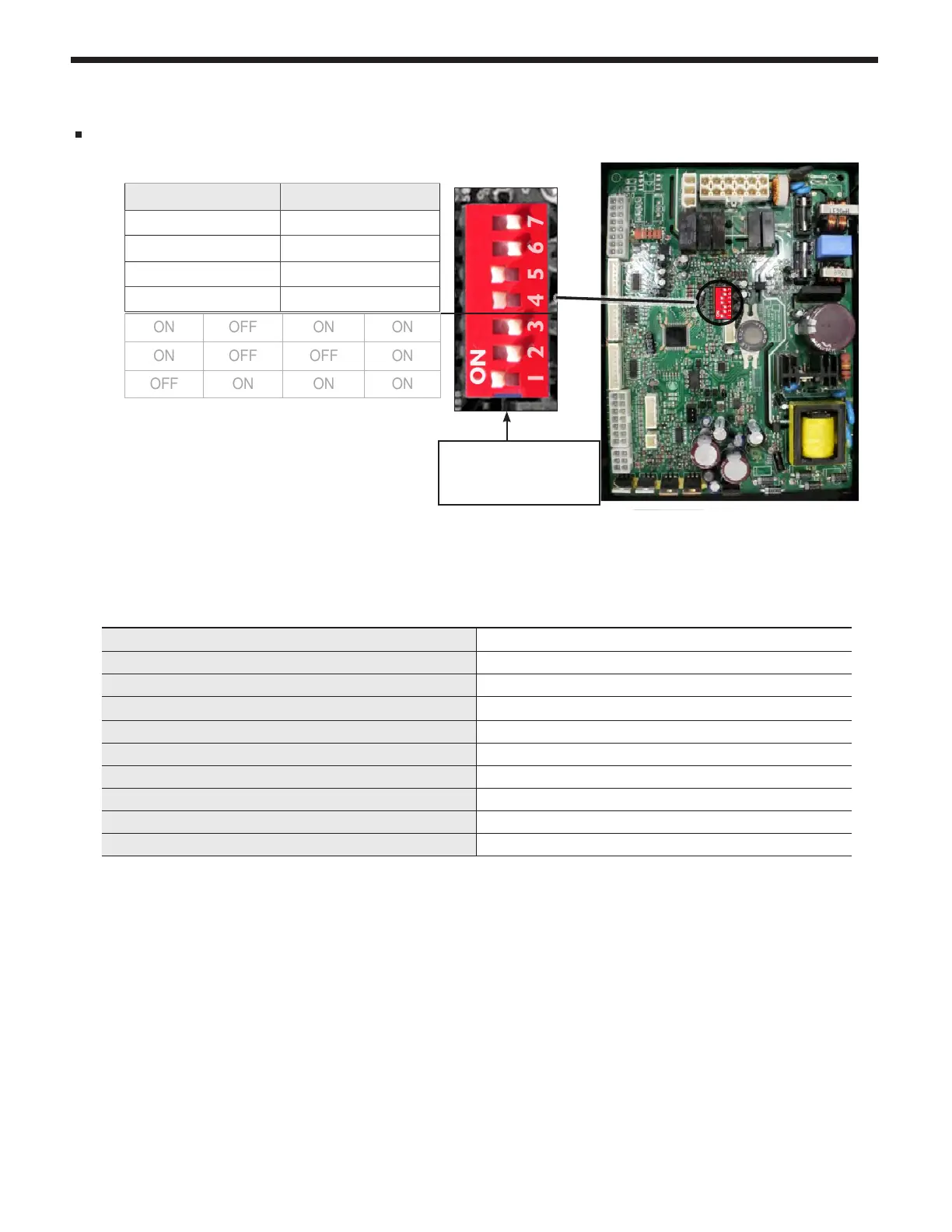

4.18 DIP Switches

System Control Setting

Maximum ame detecting voltage 2.4V

Pre-purge time (Tp) Maximum 10s, minimum 1s

Safety Time (igniting time) (Ts) 3s

Igniting interval time 10s

Post-purge time (Tip) 120S (1st : 60s + 2nd 60s)

Over-heating 1,2,3 protection detection time <3s

Pump1 post circulating time (T1pv) 60s

Pump2 post circulating time (T1pv) 60s

High & Low Water Level detection time <6s

High & Low Water Level Recover time <6s

DIP switches 6 and 7 have to be set in the OFF position when the boiler is running normally.

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355 (Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com

Document 4290C

The FT Series, Floor-Standing, Gas Conversion Kit

pg 3 of 4

Manifold pressure

Gas Type ‘NG’ Gas Type ‘LP’

2" VENT 3" VENT 2" VENT 3" VENT

FTCF140

MAX Fire

-0.15

"

WC -0.216

"

WC -0.15

"

WC -0.216

"

WC

MIN Fire

0

”

WC 0.002

”

WC 0.1

”

WC 0.079

”

WC

FTCF199

MAX Fire

-0.134

”

WC -0.173

”

WC

MIN Fire

-0.015

”

WC -0.015

”

WC

Figure D

15.

Setup your combustion Analyzer and

place the sensor into the combustion test port.

16.

Per Table B for Max Fire

,

change dip switch 6 to ON and 7 to OFF.

The unit will cycle up to MAX re.

17.

WAIT for your combustion Analyzer to stabilize. This may take up to 3 minutes depending on your combustion

Analyzer. Then check the CO

2

measurement for MAX re. Refer to Table D for acceptable MAX re

combustion readings. At this point, just record the CO

2

readings at MAX Fire. Do NOT attempt to adjust

CO

2

at MAX Fire. ONLY in MIN Fire, so...

18.

Per Table B for MIN Fire

,

change dip switch 6 to OFF and 7 to ON. The unit will cycle down to MIN Fire.

19.

WAIT for your combustion Analyzer to stabilize. Then check the CO

2

measurement at MIN re. Refer to

Table D for acceptable MIN re combustion readings.

20.

If CO

2

readings in Max Fire and MIN re are acceptable, then skip ahead to Step 23. If not, then open the

Gas Valve Adjustment Port by removing the cap screw with a 4mm Allen wrench. See Figure E.

21.

Then use the 4 mm Allen wrench to make a minor adjustment (1/8 turn) to either increase or decrease CO

2

.

Table B DIP Switch Settings

Photo shows a model

140 using 3" venting

and natural gas.

MBH 140 199

ON OFF

MIN Fire Normal Operation

MAX Fire Normal Operation

NG Natural LP Propane

3” Vent Size

2” Vent Size

ON OFF ON ON

ON OFF OFF ON

OFF ON ON ON

REFERENCE

ONLY.

CO

2

value

Gas Type ‘NG’ Gas Type ‘LP’

2" VENT 3" VENT 2" VENT 3" VENT

FTCF140

MAX Fire 8.5~10.5% 9.5~11 %

MIN Fire 8~10% 9~10.5 %

FTCF199

MAX Fire 8.5~10.0% 9.5~11 %

MIN Fire 8~10% 9~10.5 %

Table C

Table D

Loading...

Loading...