Page 6

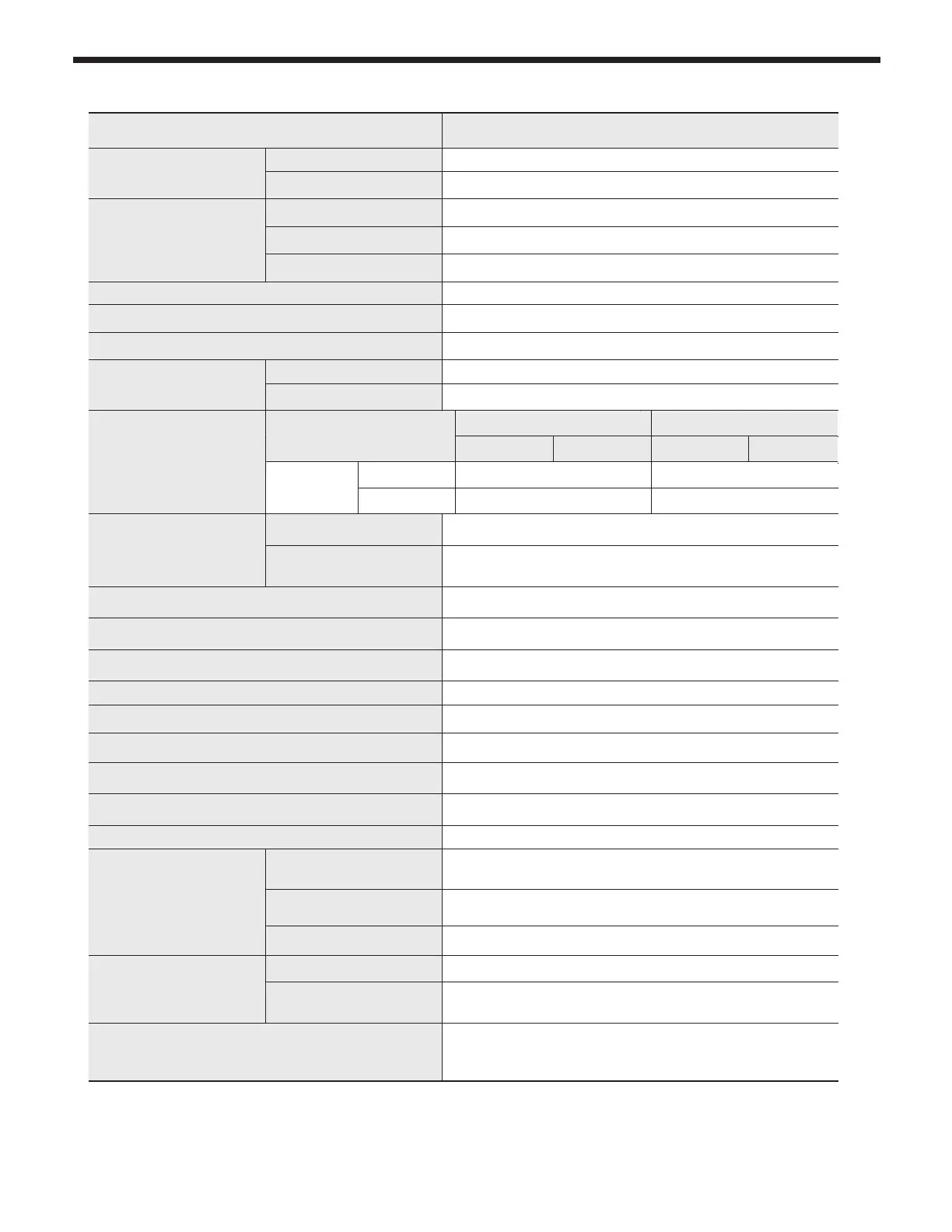

2.2 Specications

Model Name FTCF140

Gas Input Rate

MAX 140,000 Btu/h

MIN 28,000 Btu/h

Hot Water Capacity

35

°F

Rise 7.1 Gal

45

°F

Rise 5.5 Gal

77

°F

Rise 3.2 Gal

Installation Indoor / Floor stand type

Flue System Sealed Combustion Direct / Single / Concentric Vent/ SideWall Vent

Vent Run 2"(50ft) , 3"(100ft) Schedule 40 CPVC, PP

Gas Supply Pressure

NG 3.5" WC to 10.5" WC

LP 8.0" WC to 13" WC

Manifold Pressure

Gas Type LP NG

Vent size 2" VENT 3" VENT 2" VENT 3" VENT

FTCF140

Min re

-0.15

"

WC -0.216

"

WC -0.15

"

WC -0.216

"

WC

Low re

0.1

"

WC 0.079

"

WC 0

"

WC 0.002

"

WC

Power Supply

Main Supply 120V 60Hz / 6A

Maximum Power

Consumption

160W

Ignition System Direct Electronic Ignition / Automatic Flame Sensing

Burner System Single Orice Premixed Fuel Modulation Ceramic Infrared

Gas Valve System Combination modulating (Current proportional)

Minimum Flow Rate 0.5 GPM

Dimensions W15.7" - H52.4" – D26.7"

Shipping Weight 230 lbs ( 104 kg )

Sub Heat Exchanger Water Capacity(DHW) Under 15 Gallon

Main Controller / Control Panel GTX-920CP / P-920C

Water Pressure Min 15 ~ Max 150 PSI

Connection Sizes

Cold Water Inlet / Hot

Water Outlet

3/4" NPT

Space Heating

Supply / Return

1" NPT

Gas Inlet 1/2" NPT

Materials

Casing Cold Rolled Carbon Steel

Heat Exchanger

Primary Heat Exchanger : Stainless Steel

Sub Heat Exchanger : Stainless Steel

Safety Devices

Flame Rod, Overheat Cut O Device, Gas Valve Operation

Detector, Exhaust Temperature High Limit Switch, Water

Temperature High Limit Switch

800.900.9276 • Fax 800.559.1583

(Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

(Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com

Document 4290B

The FT Series, Floor-Standing, Gas Conversion Kit

pg 3 of 4

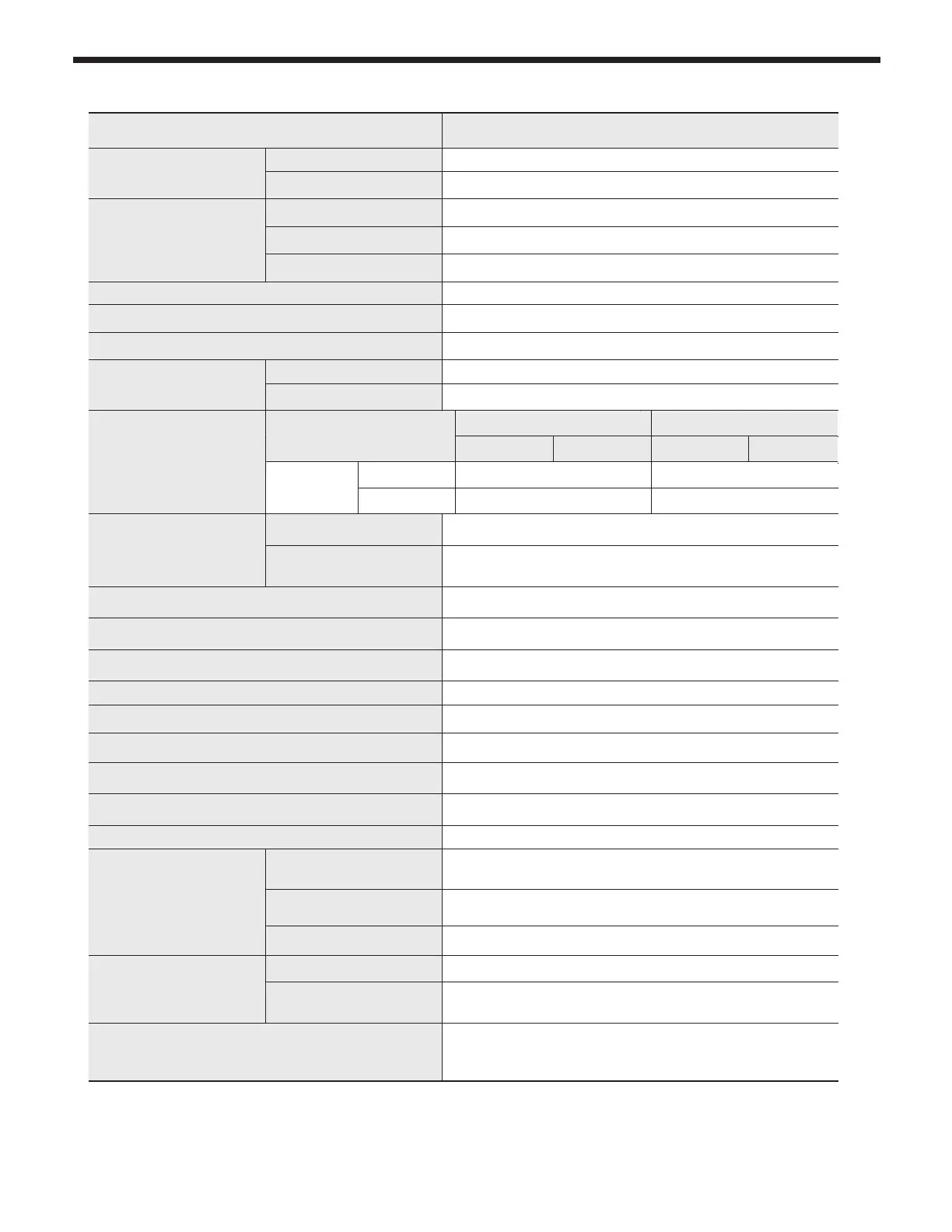

Manifold pressure

‘NG’ type combustibility ‘LP’ type combustibility

2" VENT 3" VENT 2" VENT 3" VENT

FTCF140

MAX Fire

-0.15

"

WC -0.216

"

WC -0.15

"

WC -0.216

"

WC

MIN Fire

0

”

WC 0.002

”

WC 0.1

”

WC 0.079

”

WC

FTCF199

MAX Fire

-0.134

”

WC -0.173

”

WC

MIN Fire

-0.015

”

WC -0.015

”

WC

Figure D

15.

Setup your combustion analyser and place the sensor

into the combustion test port

16.

Per Table B for Max Fire

,

change dip switch 6 to ON and 7 to OFF.

The unit will cycle up to MAX re.

17.

WAIT for your combustion analyser to stabilize. This may take up to 3 minutes depending on your combustion

analyser. Then check the CO

2

measurement for MAX re. Refer to Table D for acceptable MAX re

combustion readings. At this point, just record the CO

2

readings at MAX Fire. Do NOT attempt to adjust

CO

2

at MAX Fire. ONLY in MIN Fire, so...

18.

Per Table B for MIN Fire

,

change dip switch 6 to OFF and 7 to ON. The unit will cycle down to MIN Fire.

19.

WAIT for your combustion analyser to stabilize. Then check the CO

2

measurement at MIN re. Refer to

Table D for acceptable MIN re combustion readings.

20.

If CO

2

readings in Max Fire and MIN re are acceptable, then skip ahead to Step 23. If not, then open the

Gas Valve Adjustment Port by removing the cap screw with a 4mm Allen wrench. See Figure E.

21.

Then use the 4 mm Allen wrench to make a minor adjustment (1/8 turn) to either increase or decrease CO

2

.

Table B DIP Switch Settings

MBH N/A 140 N/A 199

ON OFF

MIN Fire Normal Operation

MAX Fire Normal Operation

NG Natural LP Propane

3” Vent Size

2” Vent Size

ON OFF ON ON

ON OFF OFF ON

OFF ON ON ON

DO

NOT

CHANGE

REFERENCE

ONLY.

CO

2

value

‘NG’ type combustibility ‘LP’ type combustibility

2" VENT 3" VENT 2" VENT 3" VENT

FTCF140

MAX Fire 8.5~10.5% 9.5~11 %

MIN Fire 8~10% 9~10.5 %

FTCF199

MAX Fire 8.5~10.0% 9.5~11 %

MIN Fire 8~10% 9~10.5 %

Table C

Table D

Loading...

Loading...