Page 72

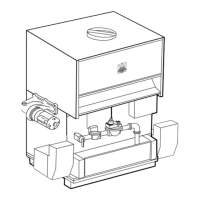

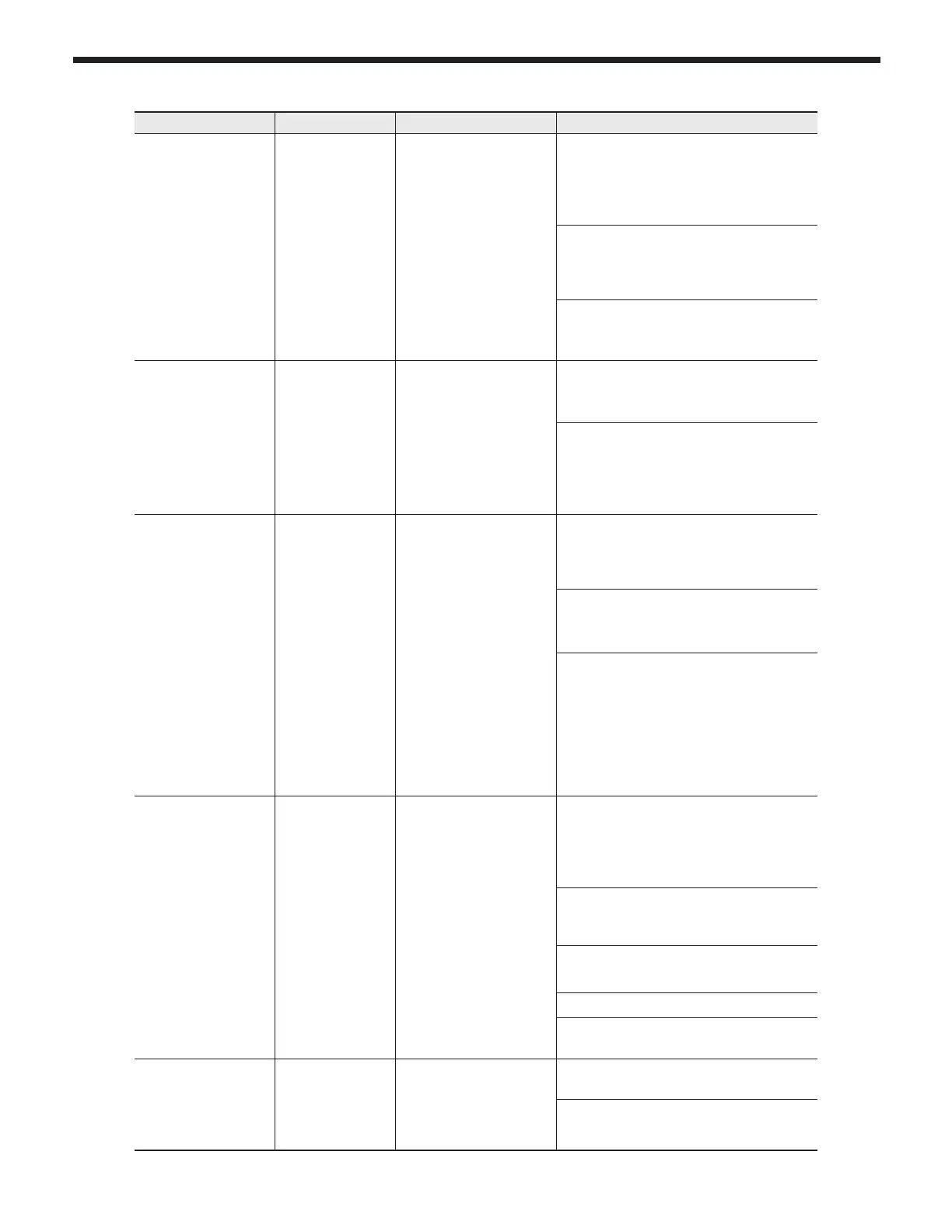

Fault Condition Diagnostic Corrective Action(s)

TEMPERATURE

SENSOR

Occurs when a

temperature

sensor has

electrically

shorted

(SHORT) or has

become

disconnected

(OPEN).

Reset using manual

reset screen on control

panel. (Power button)

Check all the temperature readings of

the boiler on the DIAGNOSTICS

- TEMPERATURES menu to determine

if any sensors are currently displayed

as SHORT or OPEN.

Check wire harness for loose

connections and pin engagement at

sensor Connection and Control

module.

If problem persists after checking items

above replace Control. Refer to repair

parts section for kit number.

FLAME FAULT

Occurs when

ame is

detected when

there should be

no ame.

Reset using manual

reset screen on control

panel.

(Power button)

Burner may be operating too hot due

to incorrect combustion. Inspect ame

and conduct combustion test.

Check for ame at burner via ame

current with burner o. Turn boiler o

and watch ame through observation

port. If ame continues after shutdown

replace gas valve.

BLOWER FAULT

Blower unable

to reach

required speed

or does not

reach 0 RPM

when turned o.

Reset using manual

reset screen on control

panel.

(Power button)

Check wire harness for loose

connections and pin engagement at

blower.

Connections.

Boiler in standby mode and blower not

running. If BLOWER SPEED is not 0

RPM then replace blower.

If blower does not rotate during ignition

sequence check for 120V power at

blower connection. If 120Vac power at

blower motor and it doesn't start

replace blower. Check power at

Control. If 120Vac is not present at

Control when boiler is powered replace

Control.

IGNITION

FAULT

Even if boiler

went through 8

ignitron

attempts, but

cannot detect

ame

Power o and on.

Dirty burner and/or heat exchanger will

cause high back pressure and poor

ignition.

Visual inspection of ue ways often will

not be able to diagnose condition.

Check incoming gas pressure with

boiler o and at Max re. Adjust within

limits on rating label.

Check for ue pipe and intake pipe

restrictions or blockage

Check burner fasteners and gaskets

Check air intake pipe and proper

propane orice

GAS VALVE

FAULT

The Control has

detected a

problem with it

gas valve

output circuit.

Reset using manual

reset screen on control

panel.

(Power button)

Check wire harness connections

between gas valve and Control.

If lockout re-occurs replace Control.

Loading...

Loading...