PLMNL0286 REV. B, Effective Date: 06/06/19 21 FiberMINI

®

with Auto Focus (AF) Operation Manual

3.4 Electrical Grounding and Noise

The capacitive sensing circuitry contained

in the FiberMINI

®

AF cutting head

measures minute changes in electrical

capacitance between the tip and earth-

ground to determine tip-to-part standoff

distance. In order for this circuit to function

properly, connect the part and the cutting

head to a good earth ground.

The ideal is to establish the ground

from a ground rod (approximately 2

meters in length) located near the

base of the machine and driven into

the ground.

Run a large gauge (1.6mm diameter

or larger) ground wire from the ground

rod to the part.

Run a separate wire from the ground

rod to the FiberMINI

®

AF.

Electrical noise can create height-sensing

issues. Large electric motors, arc welders

and other devices may be a source of

significant electrical noise. In order to

eliminate this noise, it may be necessary

to connect a ground wire to the chassis of

any such device near the process.

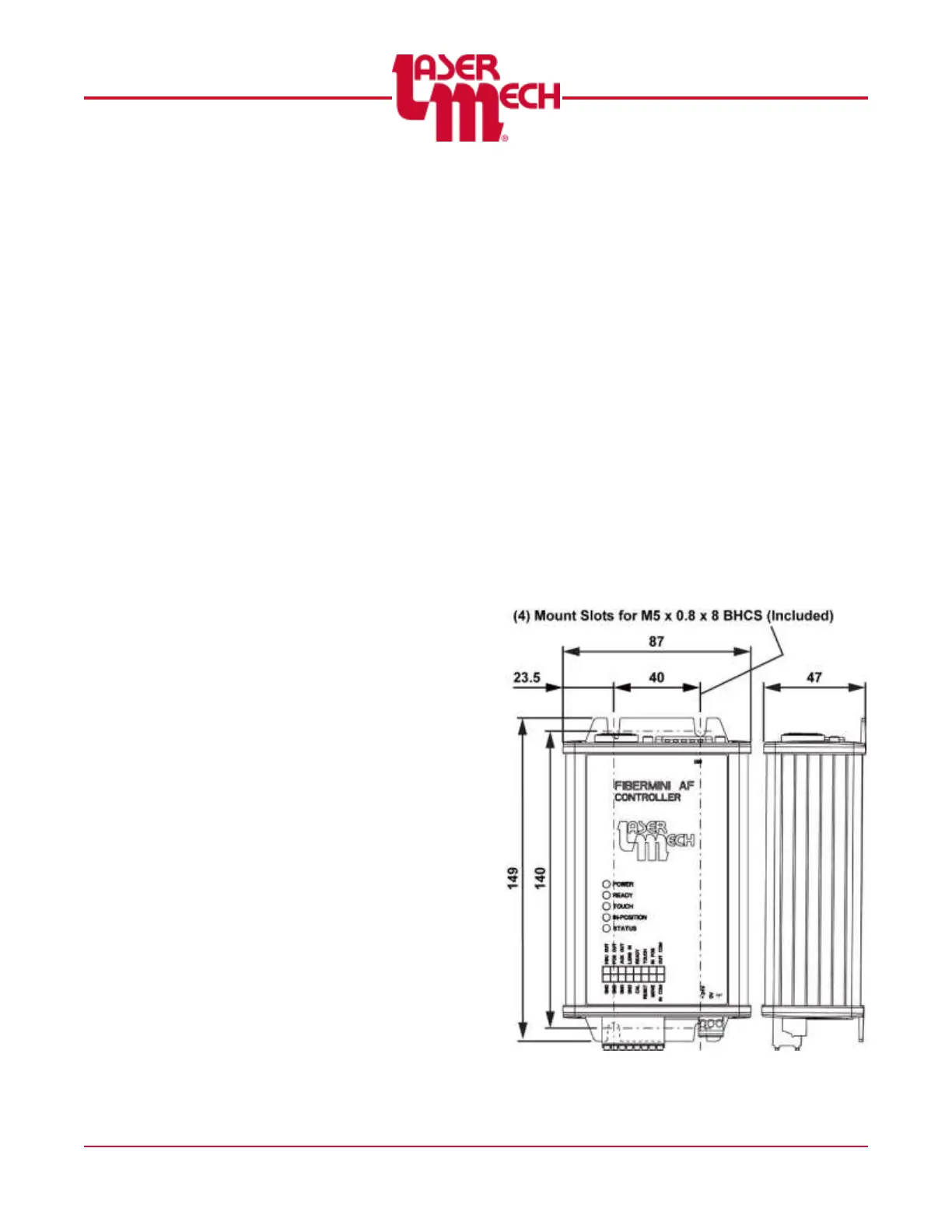

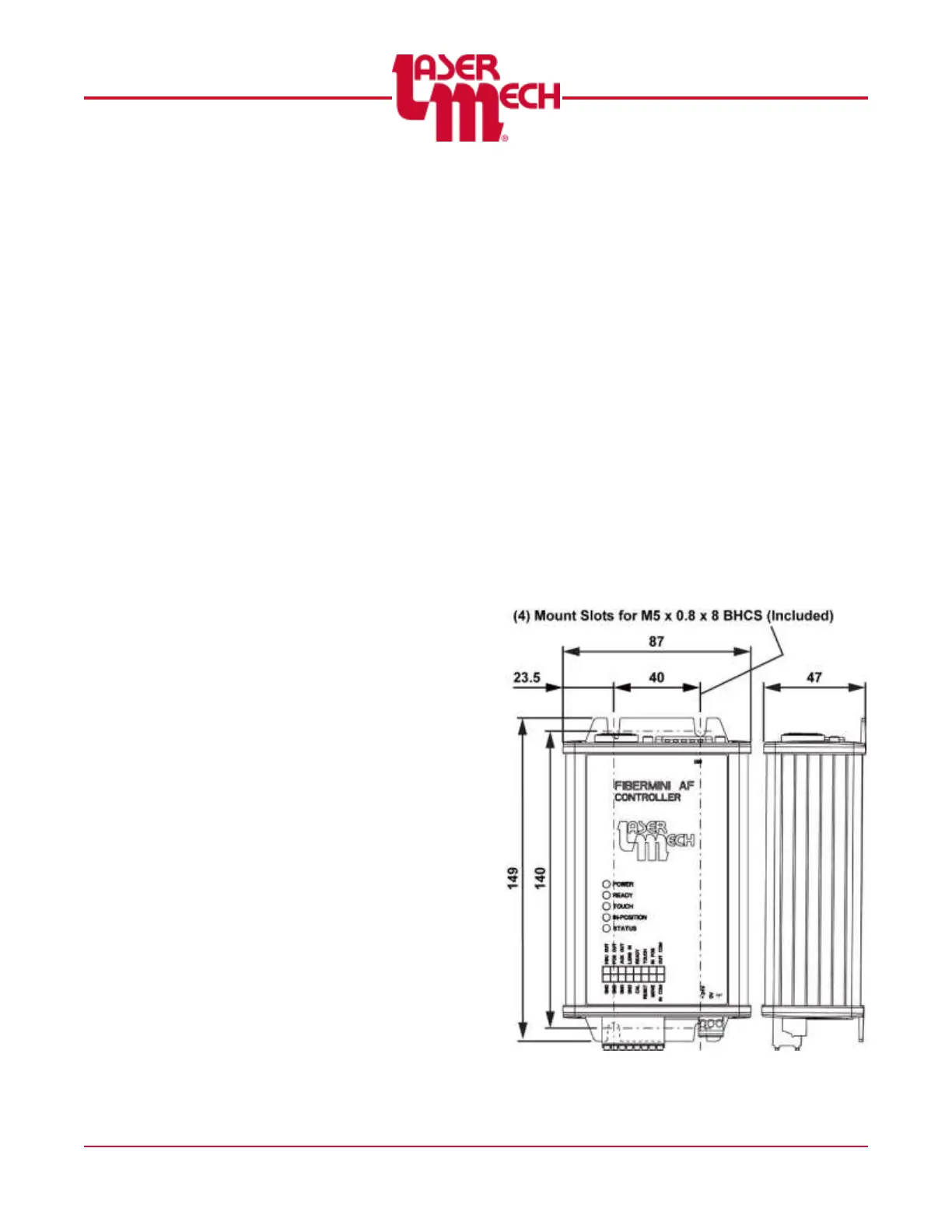

3.5 Control Box Mounting

Figure 20 illustrates the mounting pattern

for any of the control boxes and uses the

discrete I/O control box (PLCSA0081) as

an example.

Important things to consider when

mounting any of the control boxes:

Standard cable length is:

8 meters (PLCAB0608)

OR

20 meters (PLCAB0701).

Easy access for maintenance.

Mounting such that debris from the

process is not directed at the control

box.

Mounting in an area where there are

no water leaks or oils from hydraulic

lines.

Figure 20

Loading...

Loading...