Information on filling the device

n Refilling during operation is possible.

n Only operate the thermostat if a flow in the consumer system is pos-

sible. Open any shut-o valves in the consumer.

n During filling, the device may overflow if the consumer is positioned

higher than the device and filling is interrupted (e.g. due to a power

failure). There may be even larger amounts of air in the consumer, which

allows the filled liquid to flow back. In case of doubt, a shut-o valve

should be attached to the lower connection of the application.

n A vent valve Fig. 36 can significantly simplify the aeration process. For

this purpose, periodically open the valve carefully and allow gas/air to

escape until liquid escapes from the valve, and then close the vent valve

again. Collect the liquid in a suitable container. Operate the valve again

at regular intervals until no more air escapes.

Notes on fill mode in Integral XT

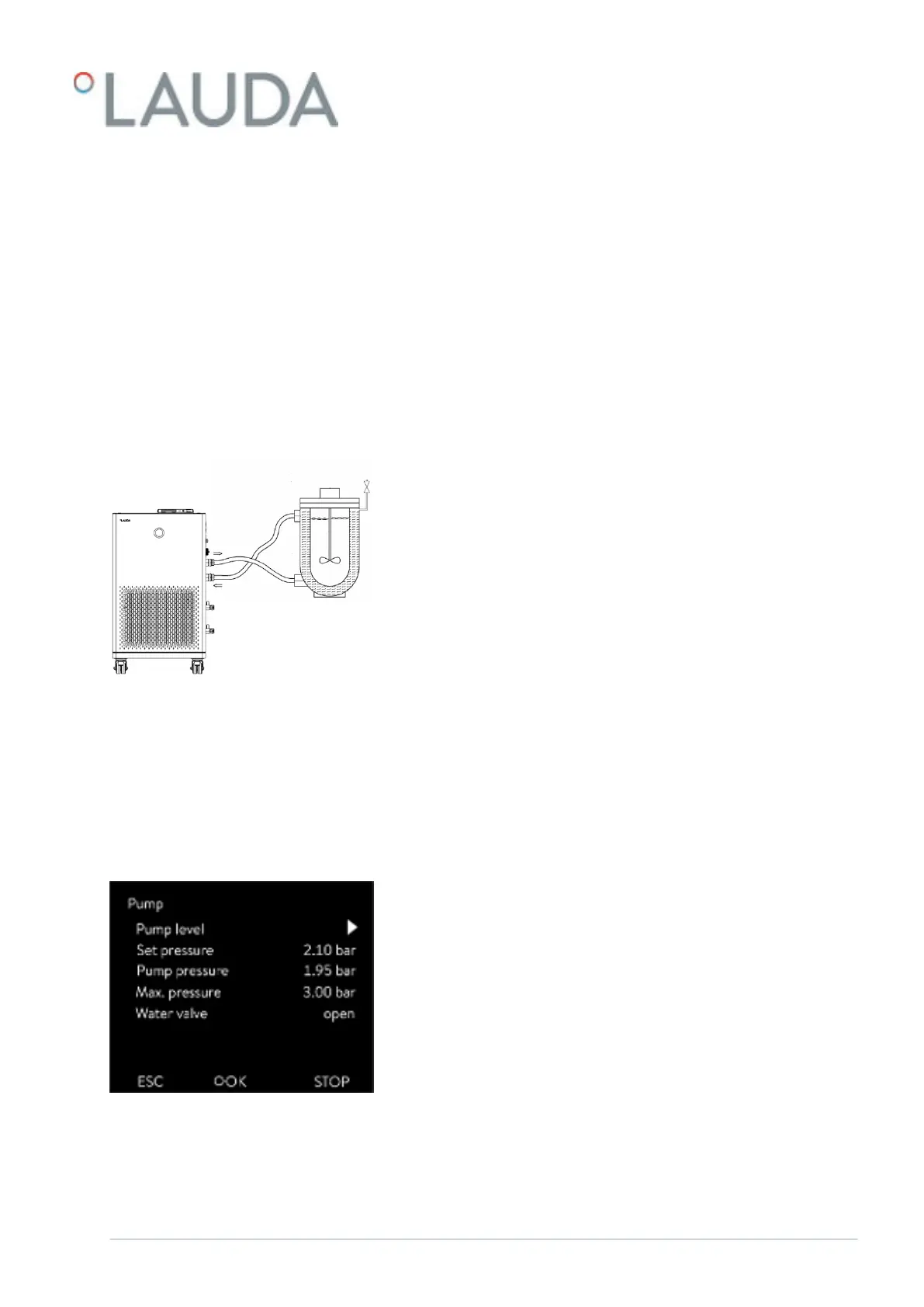

n The fill mode (only in Integral XT) supports you in filling the device.

Messages in the display guide you through the filling process. Follow the

instructions and switch on the display with the [>>] softkey.

n Furthermore, the fill mode removes gas bubbles and air bubbles from

the thermostatic circuit. The pump starts automatically at pump level 2

(IN 2560 XTW/PW: pump level 4) and switches o briefly every

45 seconds for better aeration. Heating and cooling unit are switched

o. Observe the pressure indication and level indication until the level no

longer drops, the pressure indication no longer rises and the degassing

symbol is no longer displayed for at least two minutes. Venting takes

at least a few minutes and can take more than an hour in unfavorable

conditions with large-volume consumers and high viscosity.

n For high-temperature thermostats, the switchover between the indi-

vidual hydraulic paths takes place alternately every 20 seconds. This

produces a buzzing sound of about 5 seconds. The displayed pressure

changes periodically.

Protective equipment:

n

Safety glasses

n

Protective gloves

n

Protective work clothing

1. Close the drain tap or taps. To do this, turn the tap clockwise.

2. Attach a suitable hose (heat transfer liquid/temperature) to the over-

flow connection on the device.

3. Place the end of this hose into a suitable canister to collect the

overflowing heat transfer liquid.

4. Switch on the device.

You can also switch the Integral T into standby.

Only for Integral XT: If the tank is empty (level 0), the fill mode is

started immediately after switching on the device.

5. Remove the tank lid. Use a funnel for filling, if required.

6. Carefully fill the heat transfer liquid. Check the level indicator and do

not overfill the device!

Recommendation: Fill the device up to level 6.

Fig. 36: Application with vent valve

Fill an empty device

Fig. 37: Pump menu in Integral XT

V6 Integral Process Thermostats and High-Temperature Thermostats 73 / 198

Loading...

Loading...