Installation

Electrical installation

Cable cross−sections and screw−tightening torques

5

l

25

EDS82ZAFPC201 EN 4.0

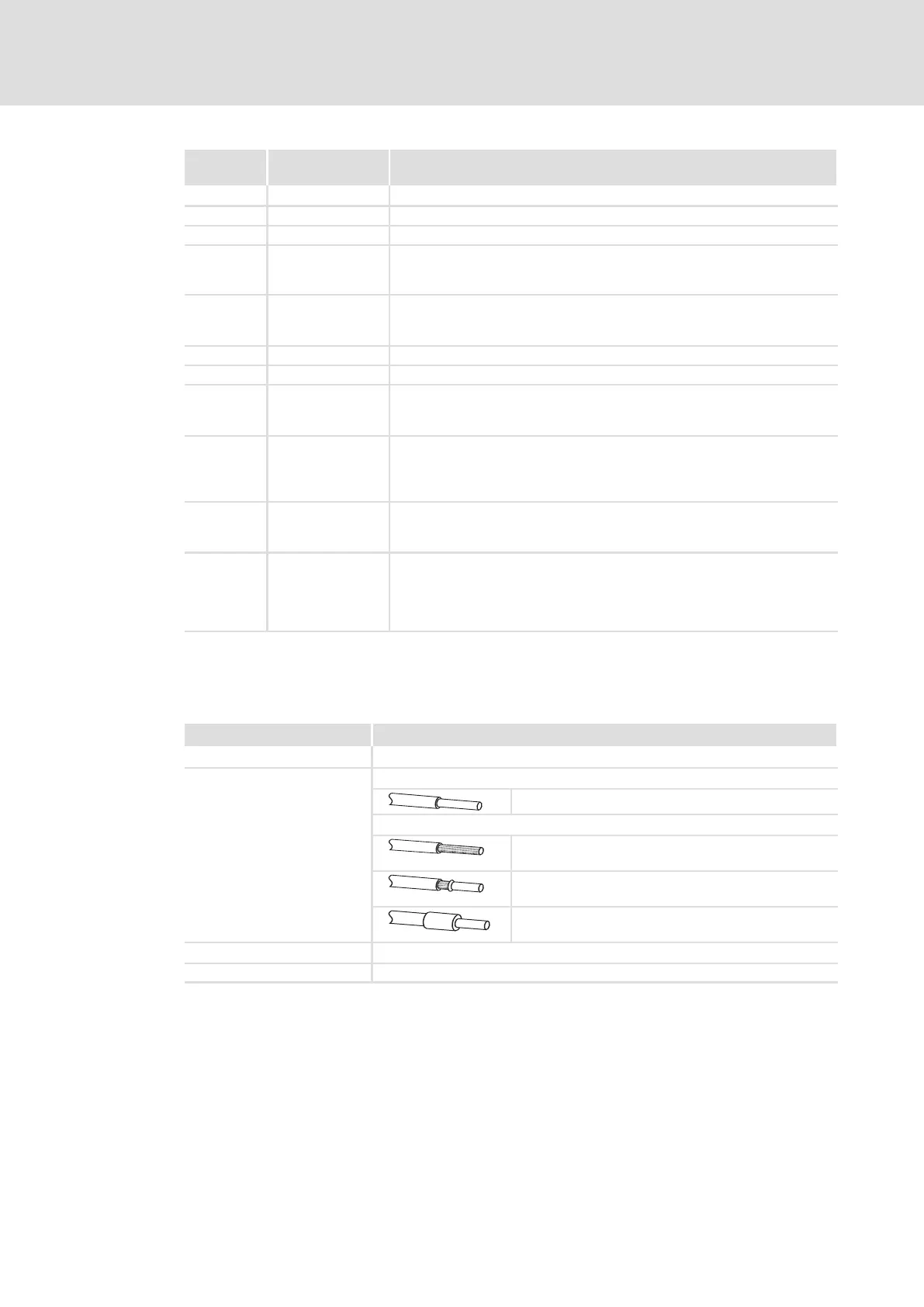

Terminal

X3.2/

Designation Function / level

+ PES Additional HF shield termination

A T/R(A) RS485 data line A

B T/R(B) RS485 data cable B

CN CNTR For function see PROFIBUS standard *)

l Level during data transmission: CNTR = HIGH

(+5 V DC, reference:GND3)

VP For function see PROFIBUS standard *)

l U = +5 V DC (reference:GND3)

l I

max

= 10 mA

40 GND3 Reference potential for PROFIBUS network *)

7 GND1 Reference potential for X3.1/20 and X3.2/20

39 GND2 Reference potential of the

l digital inputs at X3.1/E1 and X3.1/E2

l controller inhibit (CINH) at X3.2/28

28 CINH Controller inhibit

l Start = HIGH (+12 ... +30 V DC)

l Stop = LOW (0 ... +3 V DC)

(reference: GND2)

20 DC voltage source for internal supply of controller inhibit (CINH)

l +20 V DC (reference: GND1)

l I

max

= 20 mA

59 External DC voltage supply for the function module

l +24VDC±10% (reference: GND1)

l Current consumption on 24 V DC: 80 mA

The current for looping through the supply voltage to other nodes via

terminal 59 must be max. 3A.

*) E.g. for repeater connection

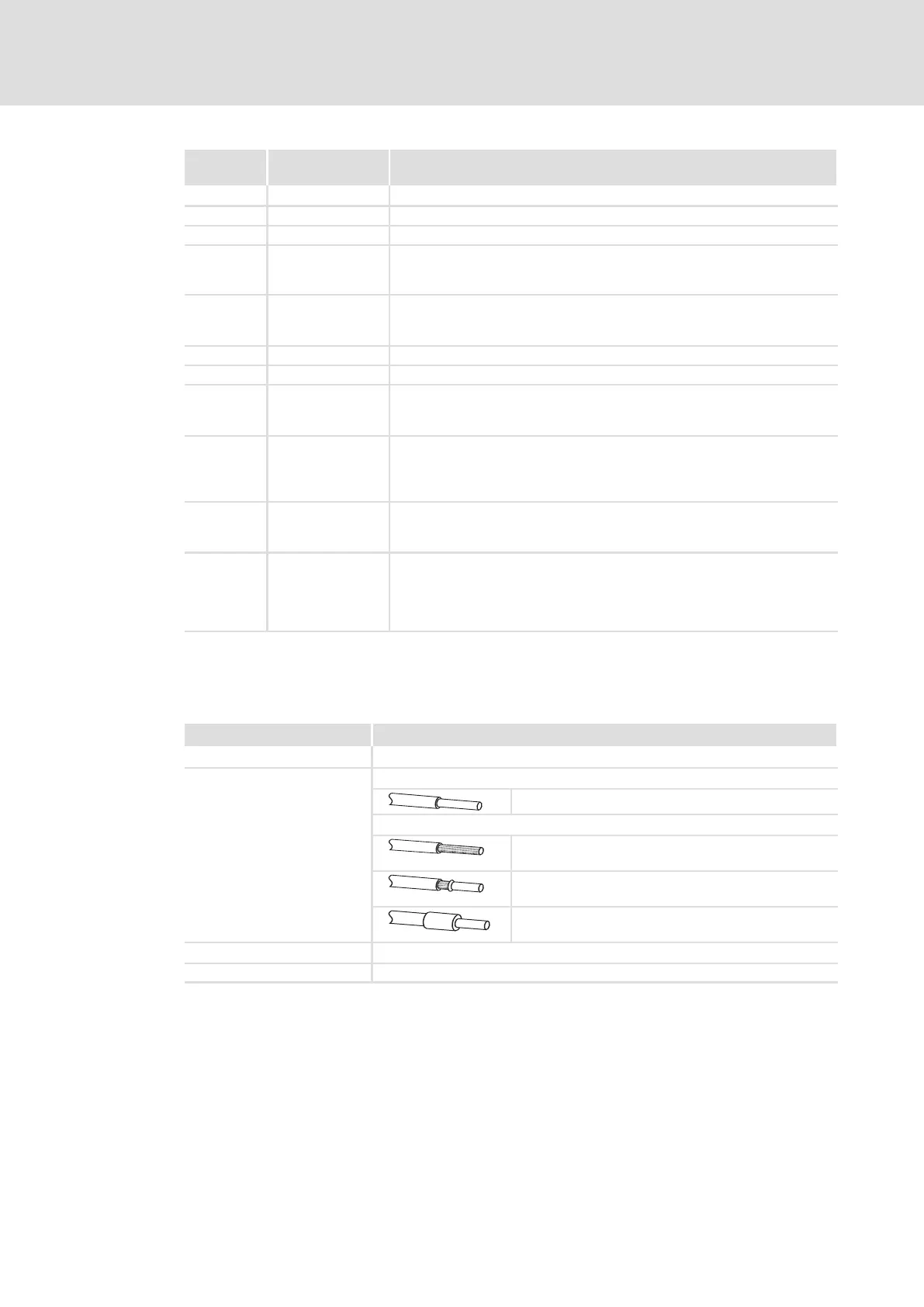

5.2.5 Cable cross−sections and screw−tightening torques

Range Values

Electrical connection Terminal strip with screw connection

Possible connections

rigid:

1.5 mm

2

(AWG 16)

flexible:

without wire end ferrule

1.0 mm

2

(AWG 18)

with wire end ferrule, without plastic sleeve

0.5 mm

2

(AWG 20)

with wire end ferrule, with plastic sleeve

0.5 mm

2

(AWG 20)

Tightening torque 0.22 ... 0.25 Nm (1.9 ... 2.2 lb−in)

Bare end 5 mm

Loading...

Loading...