USE AND MAINTENANCE MANUAL – DLC

NET

Series

LOGIC S.r.l. - M0145Db.docx

Mod. L0006A01 of 30/05/2016

2.7 Technical specifications

2.7.1 General

specifications

The conditioner and digital weight transmitter DLC

NET

is designed for interfacing to

strain gauge transducers with collecting data or industrial automation systems via

Profibus-DP

®

or Profinet

®

interface.

The board is calibrated in factory in the range of 0 ÷ 4 mV/V and does not

require no further adjustment by the customer.

The board is available in aluminum case for DIN rail mounting.

The instrument allows the transmission of data weight and diagnostics via fieldbus.

The maximum number of DLC

NET

Profibus-DP

®

is 128. The maximum number of

Profinet

®

nodes is limited by application.

In addition to these functionality, the board can be interfaced with a remote display

as a weight repeater (to be installed in safe or hazardous area) through a serial

port RS-485 (in addition to the fieldbus connection).

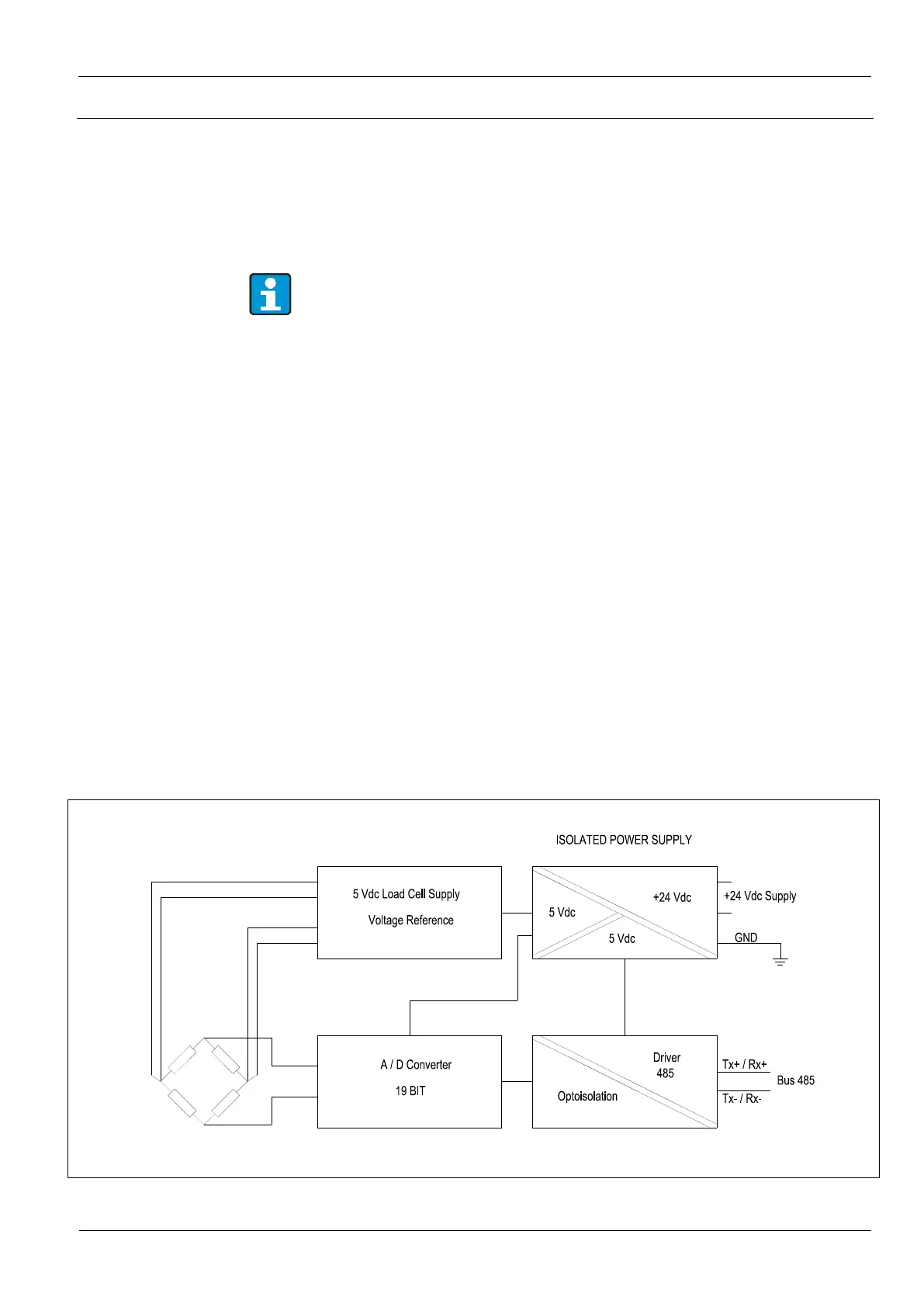

2.7.2 Principle of operation

The DLC

NET

module is a load cells signal amplifier. The supply voltage of the

transducer is 5 Vdc with the possibility of 4 or 6 wire connection. With six-wire

connection, you make a correct voltage drop compensation on the connecting

cables, for greater accuracy.

The fieldbus and power supply of the load cell are galvanically isolated via DC /

DC converter, among the 24 Vdc power supply. This allows the connection of

several weighing systems to a data collection system (PLC or PC) with the use of

the same power supply (+24 Vdc) common to other devices without any kind of

problem.

Figure 2. Diagram of operation and power supplies

Loading...

Loading...