B.VI FINAL DRIVES AND REAR WHEELS

25297

/

~~~

~--1

.

!),,

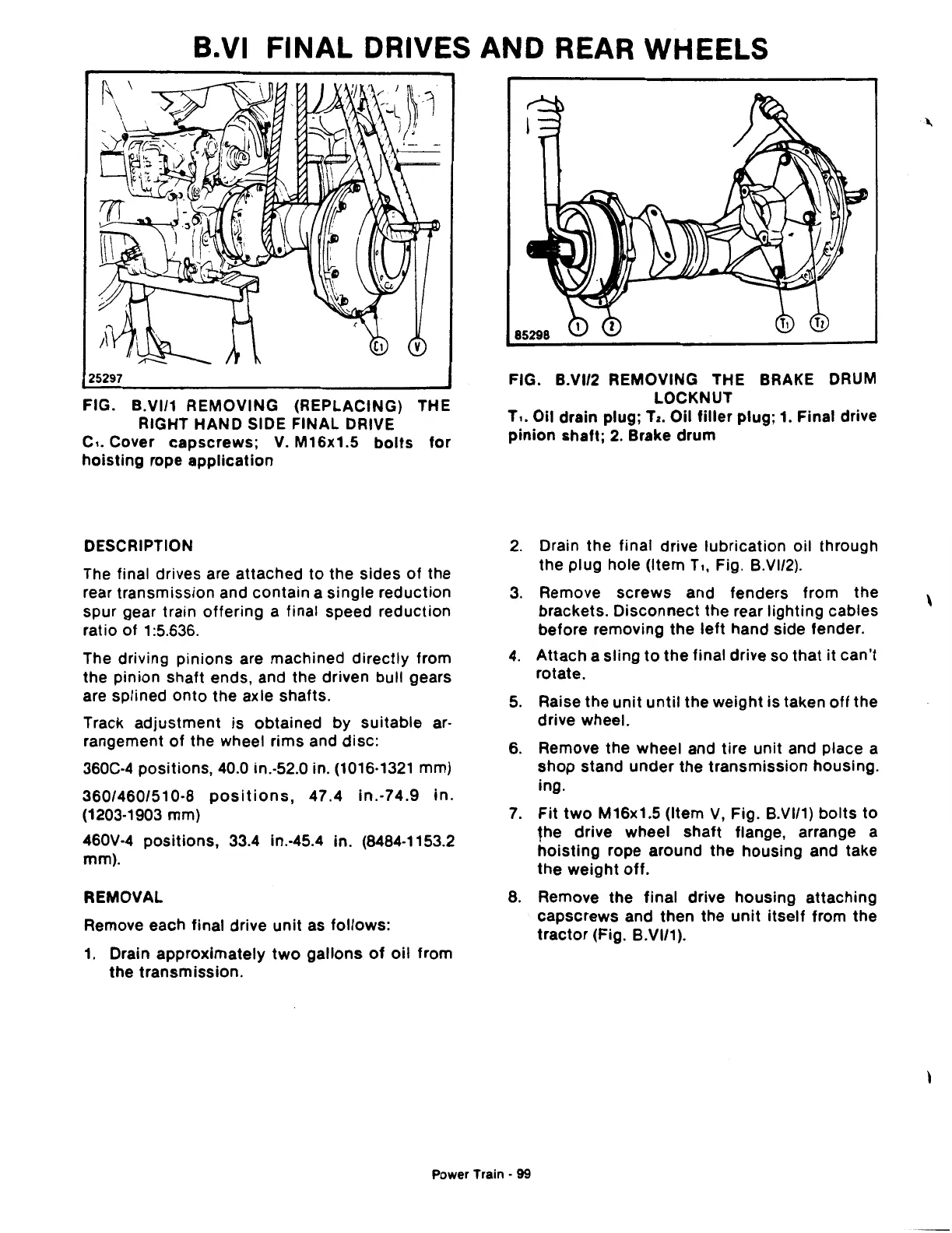

FIG. B.VI/1 REMOVING (REPLACING) THE

RIGHT HAND SIDE FINAL DRIVE

c,. Cover

capscrews;

V. M16x1.5

bolts

for

hoisting

rope

application

DESCRIPTION

The final drives are attached

to

the sides

of

the

rear transmission and contain a

single

reduction

spur gear train

offering

a final speed reduction

ratio

of

1:5.636.

The driving pinions are machined

directly

from

the pinion shaft ends, and the driven bull gears

are splined

onto

the axle shafts.

Track

adjustment

is obtained by suitable ar·

rangement

of

the wheel rims and disc:

360C-4 positions, 40.0 in.-52.0 in. (1016·1321 mm)

360/460/510-8

positions,

47.4

in.-74.9

in.

(1203-1903 mm)

460V-4

positions,

33.4 in.-45.4 in. (8484-1153.2

mm).

REMOVAL

Remove each final drive

unit

as

follows:

1.

Drain

approximately

two

gallons

of

oil

from

the

transmission.

85298

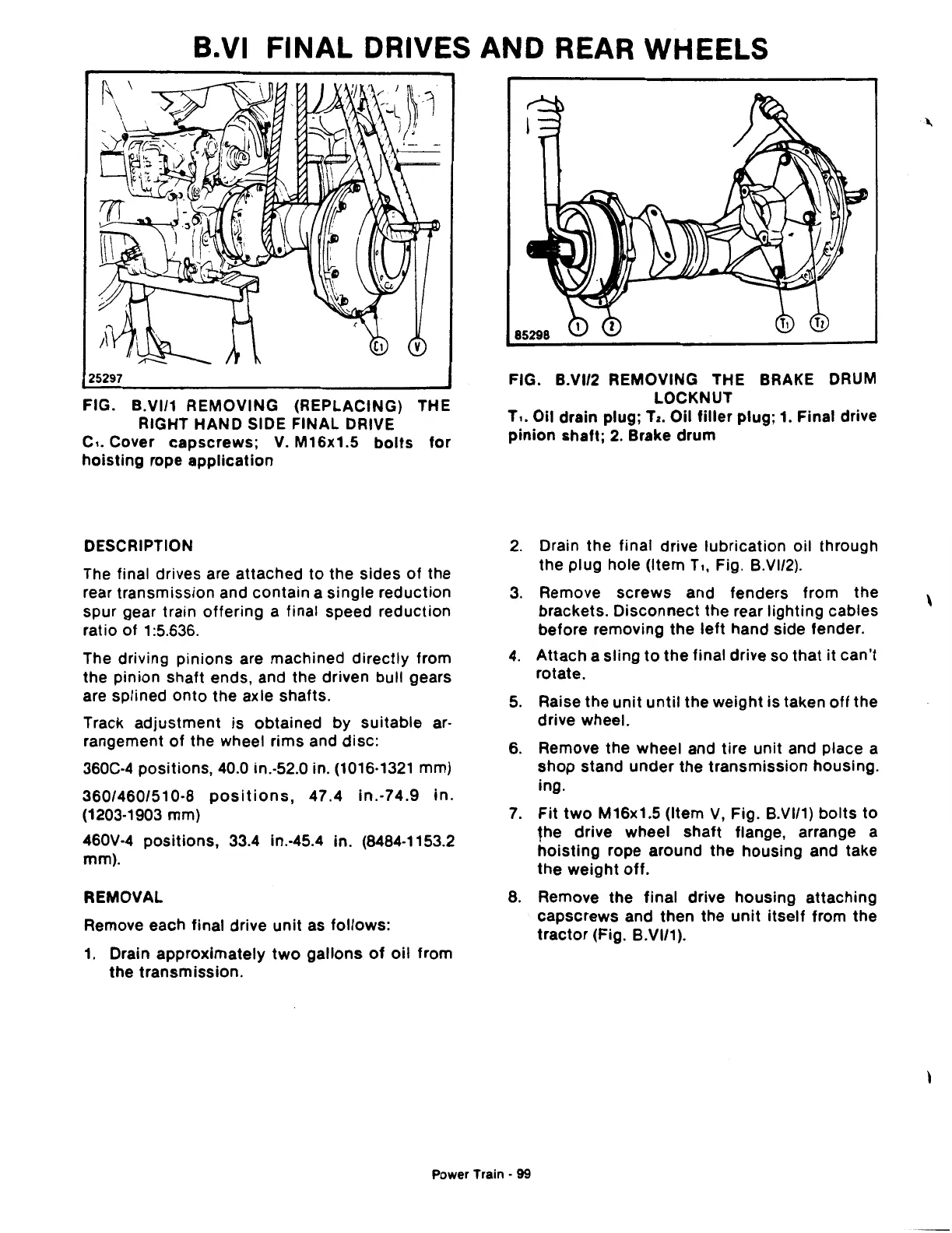

FIG. B.VI/2 REMOVING THE BRAKE DRUM

LOCKNUT

T,. Oil drain plug;

Tz.

Oil

filler

plug;

1.

Final drive

pinion

shaft;

2.

Brake

drum

2.

Drain the final drive lubrication oil through

the plug hole (Item T

,,

Fig. B.VI/2).

3.

Remove

screws

and fenders from

the

brackets.

Disconnect

the rear

lighting

cables

before removing

the

left

hand side fender.

4.

Attach

a

sling

to

the

final drive so

that

it

can't

rotate.

5.

Raise

the

unit

until

the

weight

is taken

off

the

drive wheel.

6. Remove the wheel and tire unit and place a

shop

stand

under

the

transmission

housing.

in

g.

7.

Fit

two

M16x1.5 (Item

V,

Fig. B.VI/1)

bolts

to

fhe drive wheel

shaft

flange, arrange a

hoisting

rope around the housing and take

the

weight

off.

8. Remove the

final

drive housing attaching

capscrews and then the

unit

itself

from the

tractor

(Fig. B.VI/1).

Power Train • 99

\

Loading...

Loading...