INJECTION PUMP

DESCRIPTION

Injection

pump maintains pressure

to

injectors.

To aid dependability, pump has been designed

to

eliminate failure- and wear-prone parts such as

gears and springs. Oiling is unnecessary -

pump housing contains fuel oil under pressure

to

prevent airlocks and keep

out

dust, water, and

particles

which

would reduce

efficiency

and

shorten service life.

Pump Is block-mounted, driven by a tapered

shaft

secured by a key, and revolves counter-

clockwise,

as seen from shaft end

of

pump.

Fuel enters

(48,

Fig. A.IV/8)

injection

pump,

passes through pressure-regulating valve in end

plate

(49),

through vane-type transfer pump

(25,

27,

28),

through metering valve

(42)

controlled by

throttle

arm

(36),

and

into

hollow shaft

of

rotor

(46).

Pumping pressure is applied

to

fuel by cam-

operated

pistons

(13).

Fuel then flows

to

distributor

ports

(47),

through outlet ports

(22)

to

.high-pressure connections

(21)

which feed high·

pressure lines

to

injectors.

Fuel

flow

is

controlled by a mechanical governor,

and

automatic

advance device, and by a

hydraulic damper

(97,

Fig. A.IV/7).

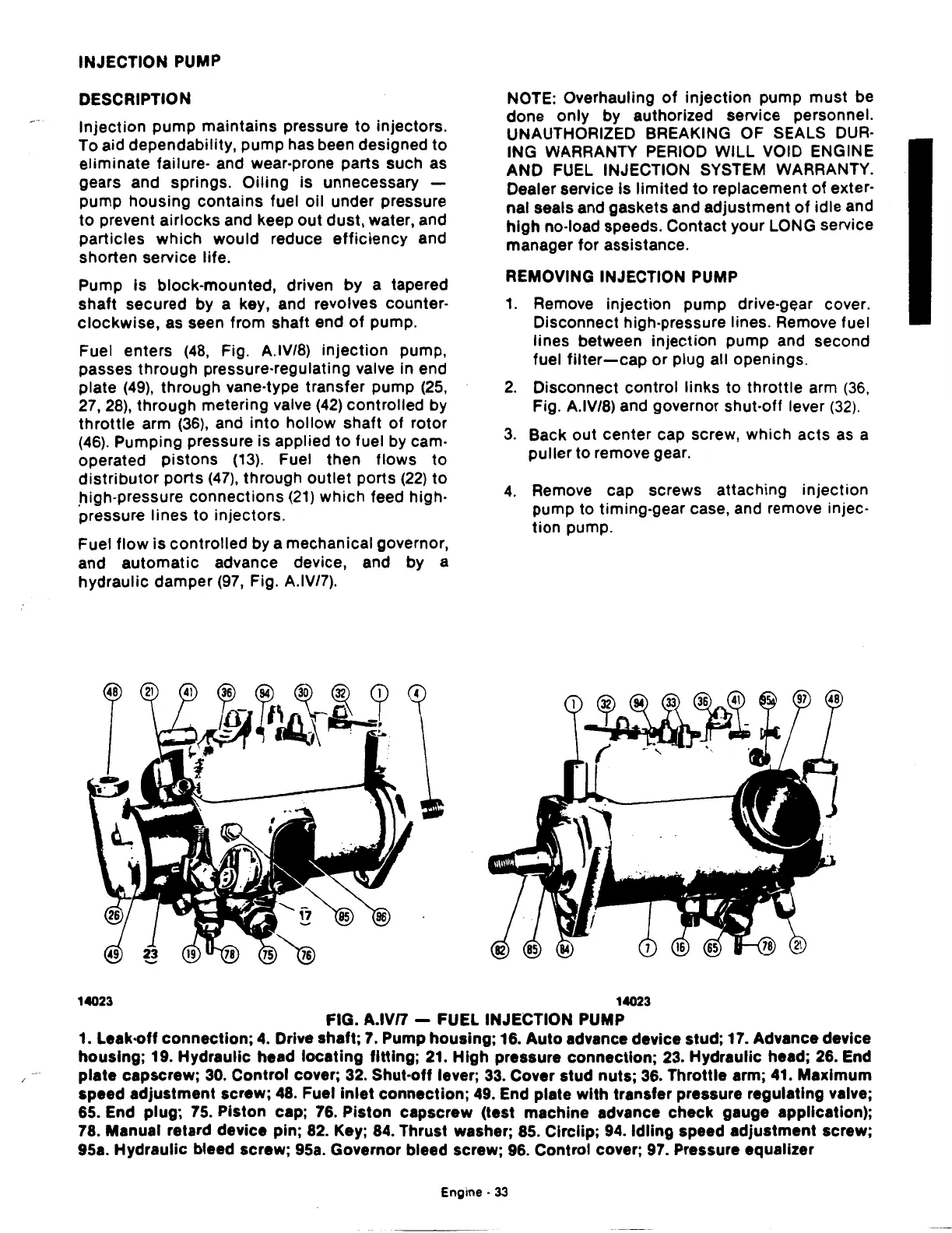

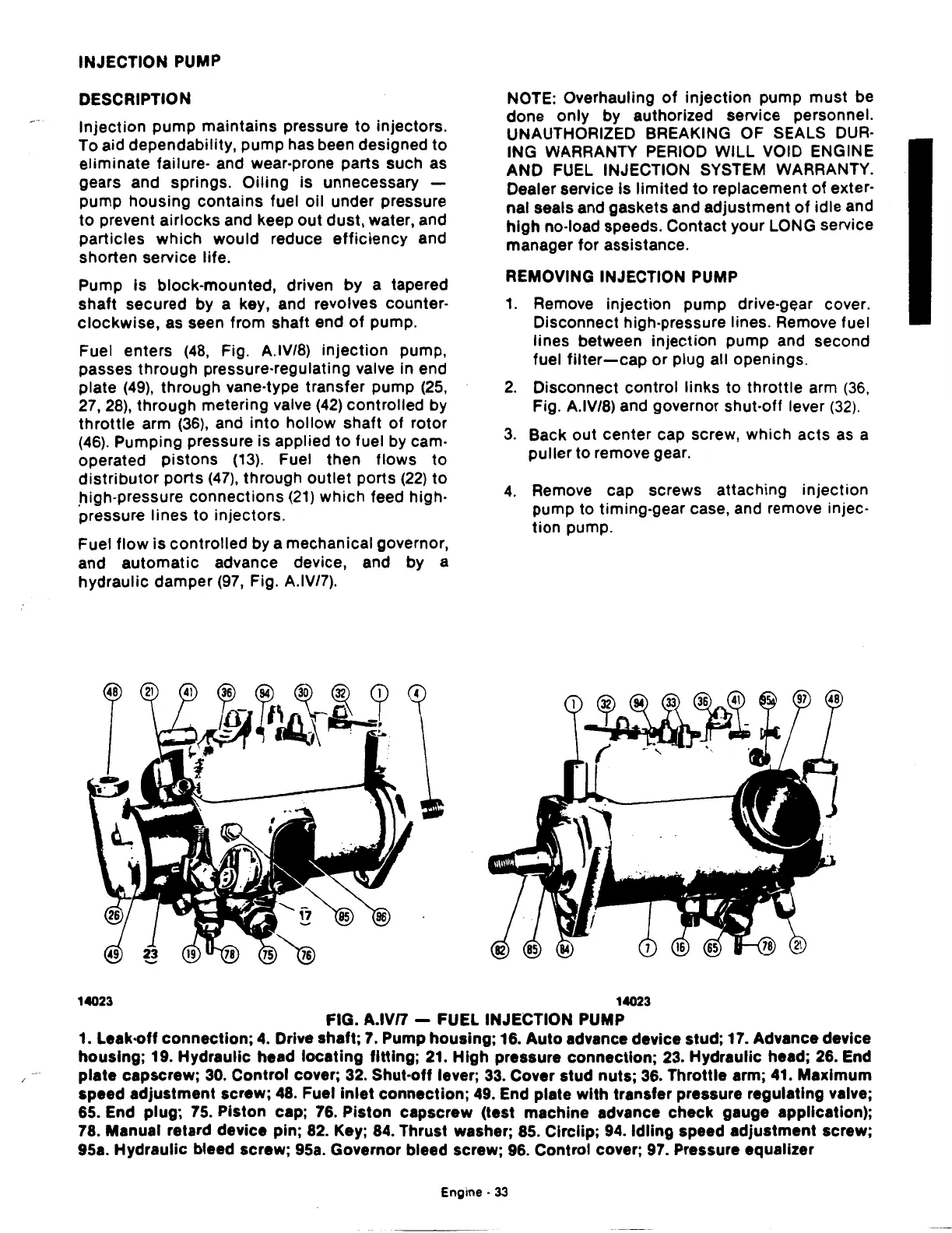

14023

NOTE: Overhauling

of

injection

pump

must

be

done only by authorized service personnel.

UNAUTHORIZED BREAKING OF SEALS

DUR-

ING WARRANTY PERIOD WILL VOID ENGINE

AND FUEL INJECTION SYSTEM WARRANTY.

Dealer service Is limited

to

replacement

of

exter·

nal seals and gaskets and adjustment

of

idle and

high

no-load speeds. Contact your LONG service

manager for assistance.

REMOVING INJECTION PUMP

1.

Remove injection pump drive-gear cover.

Disconnect high-pressure lines. Remove fuel

lines between

injection

pump and second

fuel

filter-cap

or

plug all openings.

2.

Disconnect control links

to

throttle arm

(36,

Fig. A.IV/8) and governor shut-off lever

(32).

3.

Back out center cap screw, which acts as a

puller to remove gear.

4.

Remove cap screws attaching injection

pump to timing-gear case, and remove injec-

tion

pump.

14023

FIG.

A.IVn

- FUEL INJECTION PUMP

1. Leak·off

connection;

4.

Drive shaft;

7.

Pump housing; 16.

Auto

advance device stud; 17. Advance device

housing;

19. Hydraulic head locating

fitting;

21.

High

pressure connection; 23. Hydraulic head; 26. End

plate

capscrew;

30.

Control

cover; 32. Shut·off lever;

33.

Cover stud nuts; 36. Throttle arm; 41. Maximum

speed

adjustment

screw; 48. Fuel

inlet

connection; 49. End plate

with

transfer pressure regulating valve;

65. End plug;

75.

Piston cap; 76. Piston capscrew (test machine advance check gauge application);

78. Manual retard device pin; 82. Key; 84. Thrust washer; 85. Circlip;

94.

Idling

speed adjustment screw;

95a. Hydraulic bleed screw; 95a. Governor bleed screw; 96. Control cover; 97. Pressure equalizer

Engine·

33

Loading...

Loading...