INSPECTION

Checks required

for

the

10"

clutch

are as

follows:

1. Functional

efficiency

of

the

disc

friction

lin-

ings (Items

1 and 8, Fig.-8.1/5) and

conditions

of

mating

metallic

surfaces. The

latter

are

polished,

if

necessary. If the

discs

are im-

pregnated

with

oil

it

is

best

to

replace them,

as washing in solvent and

brushing

are

not

enough.

2.

The

friction

surfaces

of

the pressure plates

should be free from scoring

or

signs

of

ab-

normal wear, and if so

it

is

possible

to reface

them by

turning

them down on a lathe (see

"Fits

and

Tolerances"

table).

3.

The hubs of the driven plates should have no

play on the rivets.

4. The side clearance

of

the

disc

hub

splines

with the splined shafts.

5.

The

condition

of

the throw-out collar

thrust

beanng and of the

clutch

shaft

pilot

bearing

in the flywheel.

6.

Loading

spring

strain

values

versus

specifications

in

"Fits·

and Tolerances'"

table.

7. Sliding surface

conditions

of

throw-out

collar

and support. If wear is

still

within

limits.

the

support can be rotated

180

•,

and

if

not.

replace the parts

if

excessive play causes

grease leakage.

10"

CLUTCH ASSEMBLY

Prior

to

assembly, lubricate the

following

items

with

a film of lithium-base grease:

transmission

clutch

release lever pivots, the ball heads

of

the

clutch

release rods (mainly

to

hold them in place

at assembly), the

outer

surfaces

of

the forks

of

the pressure plates (Items 3 and

6.

Fig.

8.115)

and

the inside surface

of

the fork

locations

on the

clutch

cover (Item

10).

Assemble the

clutch

referring

to

the

following

notes:

1. Place the pressure plate (Item

3,

Fig.

8.1/5).

adjusting

screw (Item

7)

supporting

plate.

pressure plate (Item

6)

and

the

clutch

cover

(Item

10)

in

their

original

positions

arranging

them

with

their

assembly marks (scribed at

disassembly) in register.

2.

Install the

transmission

clutch

disc

(Item

8)

with

the

oil

slinger

away from the flywheel.

3.

Tighten the

attaching

cam

screws

(Item

C2,

Fig.

8.1/4)

to

the

torque value

specified

in the

"Torque

Specifications"

table.

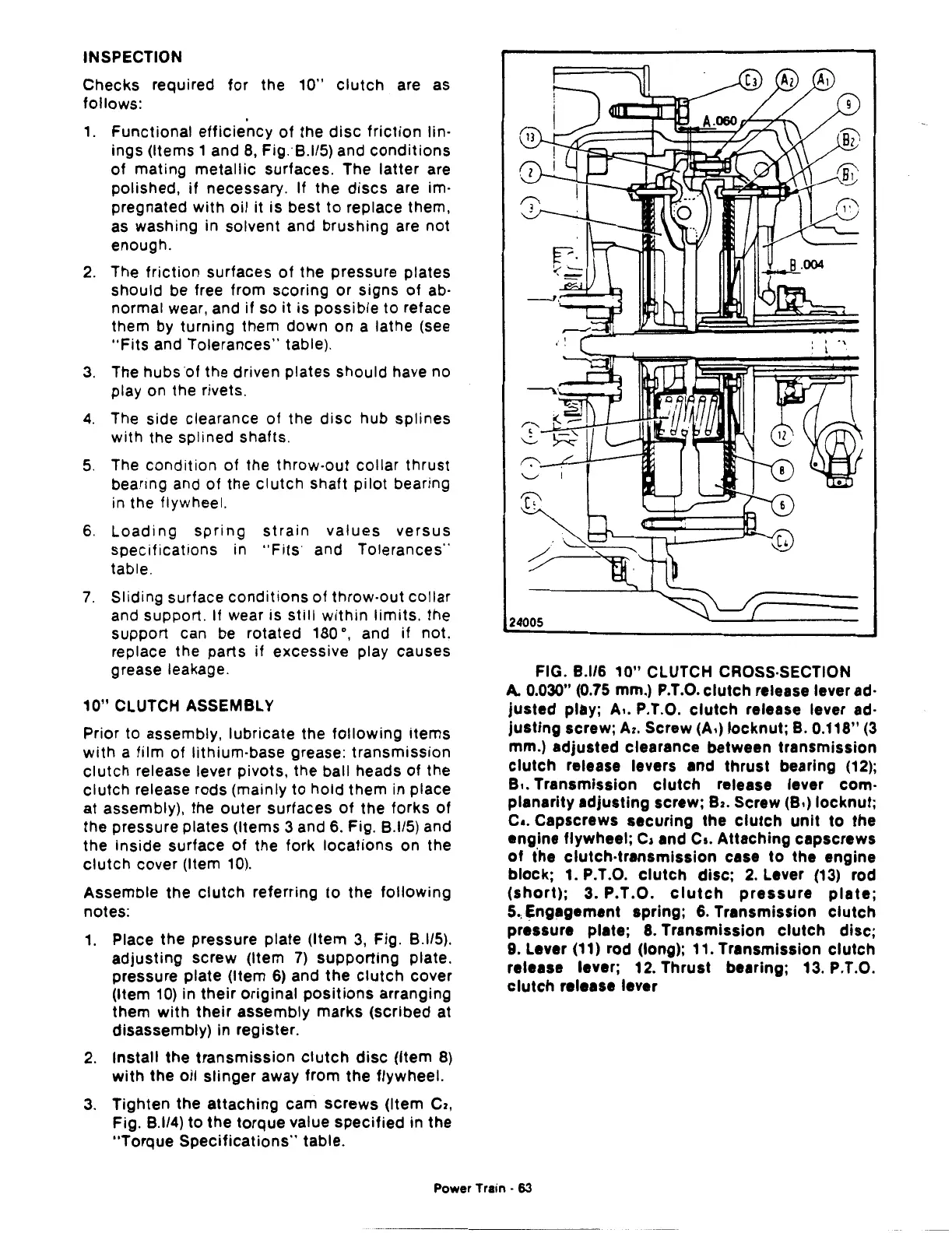

FIG.

8.1/6

10"

CLUTCH CROSS-SECTION

A.

0.030" (0.75 mm.)

P.T.O.

clutch release lever

ad-

justed play; A

•.

P.T.O.

clutch

release lever

ad-

justing screw;

A2.

Screw (A·) locknut;

B.

0.118"

(3

mm.) adjusted clearance between transmission

clutch

release levers and thrust bearing

(12);

B

•.

Transmission

clutch

release lever com-

planarity adjusting screw;

Bz.

Screw (8•) locknut;

c

•.

Capscrews securing the clutch unit to the

eng.ine flywheel;

c, and

Cs.

Attaching capscrews

of

the clutch·transmission case to the engine

block;

1. P.T.O.

clutch

disc;

2.

Lever (13) rod

(short);

3. P.T.O.

clutch

pressure

plate;

5.,

Engagement spring;

6.

Transmission clutch

pressure plate;

8.

Transmission clutch disc;

9.

Lever (11) rod (long); 11. Transmission clutch

release lever;

12. Thrust bearing; 13. P.T.O.

clutch

release lever

Power Train ·

63

Loading...

Loading...