'

After

assembly, make sure that:

1.

The valves are recessed below

the

cylinder

head lower surface as specified (Fig. A.l/5).

2.

The upper spring·

cup

(Item 17, Fig. A.ll/7)

locks

(Item

18)

seat perfectly in

their

seats.

3.

Valve rod ends are

fitted

with caps (Item

19).

A CAUTION: The fuel shut-off on

this

engine is

spring loaded in the

"FUEL

ON"

position.

When turning the engine by hand,

to

adjust

valves, etc. the fuel

stop

will

have

to

be

held in

the

"OFF"

position which is

out

because under

certain

conditions

the engine could start.

VALVE GAP ADJUSTMENT

Intake:

Exhaust:

.010 in. (0.254 mm.)

.010 in. (0.254 mm.)

Adjustment

of

the gap between valves and

rocker arms can be made on engines installed or

removed from tractor, as follows:

1.

Turn the crankshaft until the first piston is at

T.D.C. at beginning

of

intake stroke and

valves are in balanced position. This position

of

piston 1 is set when the mark "P.M.S.

1"

stamped on the flywheel rim is in register

with

the pointed (Fig. A.ll/12).

2.

Turn the crankshaft one full revolution, bring·

ing the mark "P.M.S.

1"

back

to

the previous

position.

3.

Set the intake and exhaust valve gap on

cylinder 1 using the special wrench and a

feeler gauge (Fig. A.ll/10).

4.

Repeat for all remaining pairs

of

valves,

holding in mind that the stamped mark

"P.M.S.

1"

does not apply

to

pistons

2 and

3.

Consequently mark the position correspon-

ding

to

T.D.C. at intake on the flywheel with

chalk.

TAPPETS, PUSH RODS AND ROCKER ARMS

Tappets and push rods are located in the

left

side

or

crankcase. Removal

of

tappets

must

be

preceded

by

the removal

of

the camshaft and

of

the

oil

sump. Inspections and

checks

are the

following:

1.

Inspect

finish

of

surfaces contacting the

shaft

cams. Smooth

out

scoring,

if

any, with

a fine grained carborundum stone.

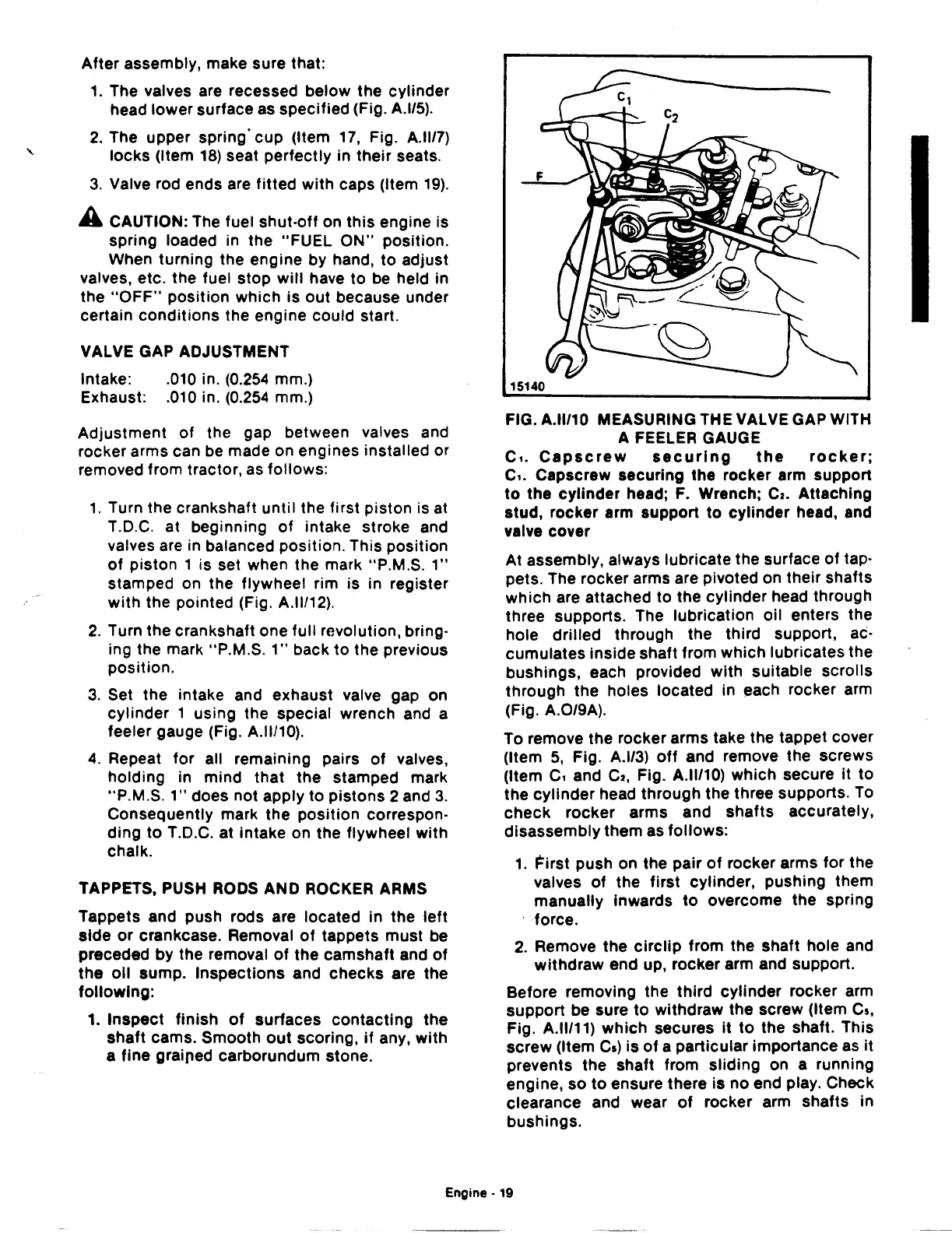

FIG. A.ll/10 MEASURING THE VALVE GAP WITH

A FEELER GAUGE

c,.

Capscrew

securing

the

rocker;

c,. Capscrew securing the rocker arm support

to

the

cylinder

head; F. Wrench;

Cz.

Attaching

stud, rocker arm support

to

cylinder head, and

valve cover

At assembly, always lubricate the surface

of

tap-

pets. The rocker arms are pivoted on their shafts

which are attached to the cylinder head through

three supports. The lubrication oil enters the

hole

drilled

through the third support, ac-

cumulates inside shaft from which lubricates the

bushings, each provided

with

suitable

scrolls

through the holes located in each rocker arm

(Fig. A.0/9A).

To remove the rocker arms take the tappet cover

(Item

5,

Fig. A.l/3)

off

and remove the screws

(Item

c,

and

Cz,

Fig. A.ll/10) which secure

it

to

the

cylinder

head through the three supports. To

check

rocker

arms and

shafts

accurately,

disassembly them as follows:

1.

First push on the pair

of

rocker arms

for

the

valves

of

the

first

cylinder, pushing them

manually Inwards

to

overcome the spring

force.

2.

Remove the

circlip

from the shaft hole and

withdraw end up, rocker arm and support.

Before removing the

third

cylinder rocker arm

support be sure

to

withdraw the screw (Item

Cs,

Fig. A.ll/11) which secures It

to

the shaft. This

screw (Item

Ca)

is

of

a particular importance as

it

prevents the shaft from sliding on a running

engine, so

to

ensure there is

no

end play. Check

clearance and wear

of

rocker arm shafts in

bushings.

Engine·

19

Loading...

Loading...