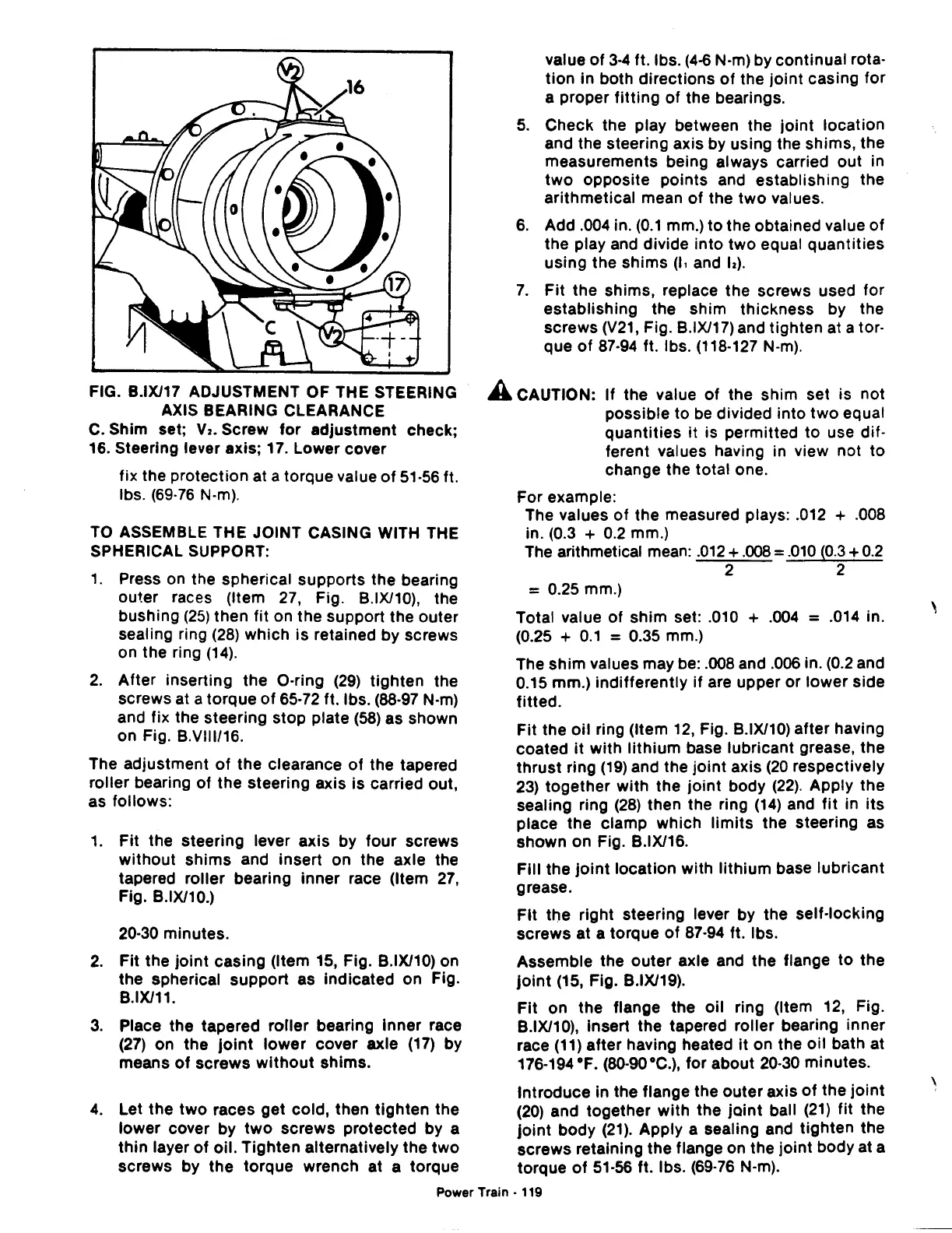

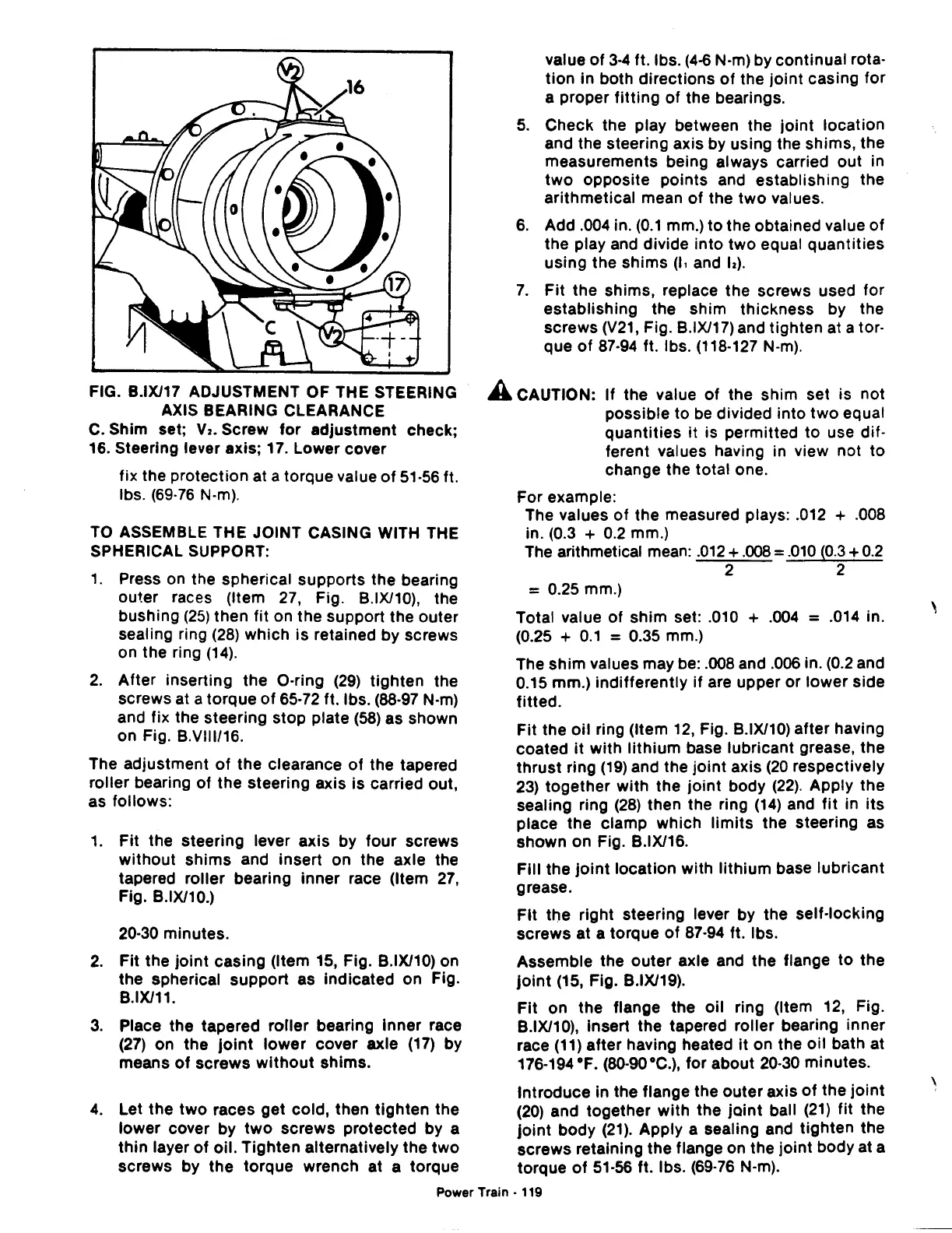

FIG. B.IX/17 ADJUSTMENT OF THE STEERING

AXIS BEARING CLEARANCE

C.

Shim set;

Vz.

Screw

for

adjustment check;

16. Steering lever axis; 17. Lower cover

fix the protection at a torque value

of

51·56 ft.

lbs.

(69·76

N-m).

TO

ASSEMBLE THE JOINT CASING WITH THE

SPHERICAL SUPPORT:

1.

Press on the spherical supports the bearing

outer races (Item 27, Fig. B.IX/10), the

bushing

(25)

then

fit

on the support the outer

sealing ring

(28)

which

is

retained by screws

on the ring

(14).

2.

After inserting the

0-ring

(29)

tighten the

screws at a torque

of

65·72 ft. lbs.

(88-97

N-m)

and fix the steering stop plate

(58)

as shown

on Fig. B.VIII/16.

The adjustment

of

the clearance

of

the tapered

roller bearing

of

the steering axis is carried out,

as follows:

1.

Fit

the steering lever axis by four screws

without

shims

and insert on the axle the

tapered roller bearing inner race (Item 27,

Fig. B.IX/10.)

20-30 minutes.

2.

Fit the

joint

casing (Item 15, Fig. B.IX/10) on

the spherical support as indicated on Fig.

B.IX/11.

3.

Place the tapered

roller

bearing Inner race

(27)

on the

joint

lower

cover axle

(17)

by

means

of

screws

without

shims.

4.

Let the

two

races get cold, then

tighten

the

lower cover by

two

screws protected by a

thin layer

of

oil. Tighten alternatively the

two

screws by

the

torque wrench at a torque

value

of

3-4ft. lbs.

(4-6

N-m) by continual rota-

tion

in both directions

of

the

joint

casing

for

a proper

fitting

of

the bearings.

5.

Check the play between the

joint

location

and the steering axis by using the shims, the

measurements being always carried

out

in

two

opposite points and establishing the

arithmetical mean

of

the

two

values.

6.

Add .004 in.

(0.1

mm.) to the obtained value

of

the play and divide

into

two

equal

quantities

using the

shims

(1,

and

lz).

7.

Fit

the shims, replace the screws used for

establishing the shim thickness by the

screws

(V21,

Fig. B.IX/17) and tighten at a tor-

que

of

87-94

ft. lbs. (118-127 N-m).

A CAUTION: If the value

of

the shim set is not

possible

to

be

divided

into

two

equal

quantities

it

is permitted

to

use dif-

ferent values having in view not

to

change the total one.

For example:

The values

of

the measured plays: .012 + .008

in. (0.3

+

0.2

mm.)

The arithmetical mean:

.012

+

.008

=

.010

(0.3

+

0.2

2 2

= 0.25 mm.)

Total value

of

shim set: .010 + .004 = .014 in.

(0.25

+

0.1

= 0.35 mm.)

The

shim

values may be: .008 and .006 in.

(0.2

and

0.15 mm.) indifferently

if

are upper or

lower

side

fitted.

Fit the

oil

ring (Item 12, Fig. B.IX/10) after having

coated

it

with

lithium

base lubricant grease, the

thrust

ring

(19)

and the

joint

axis

(20

respectively

23) together

with

the

joint

body

(22).

Apply the

sealing ring

(28)

then the ring

(14)

and

fit

in

its

place

the

clamp which

limits

the steering as

shown on Fig. B.IX/16.

Fill

the

joint

location

with

lithium

base lubricant

grease.

Fit

tt)e right steering lever by the self-locking

screws at a torque

of

87-94

ft. lbs.

Assemble the

outer

axle and the flange

to

the

joint

(15,

Fig. B.IX/19).

Fit

on

the

flange the

oil

ring (Item 12, Fig.

B.IX/10), Insert the tapered roller bearing inner

race

(11)

after having heated

it

on the

oil

bath at

176-194 •F. (80·90·C.), for about 20-30 minutes.

Introduce in the flange the

outer

axis

of

the

joint

(20)

and together

with

the

joint

ball

(21)

fit

the

joint

body

(21).

Apply a sealing and tighten the

screws retaining the flange on the

joint

body at a

torque

of

51·56 ft. lbs.

(69-76

N-m).

Power

Train·

119

Loading...

Loading...